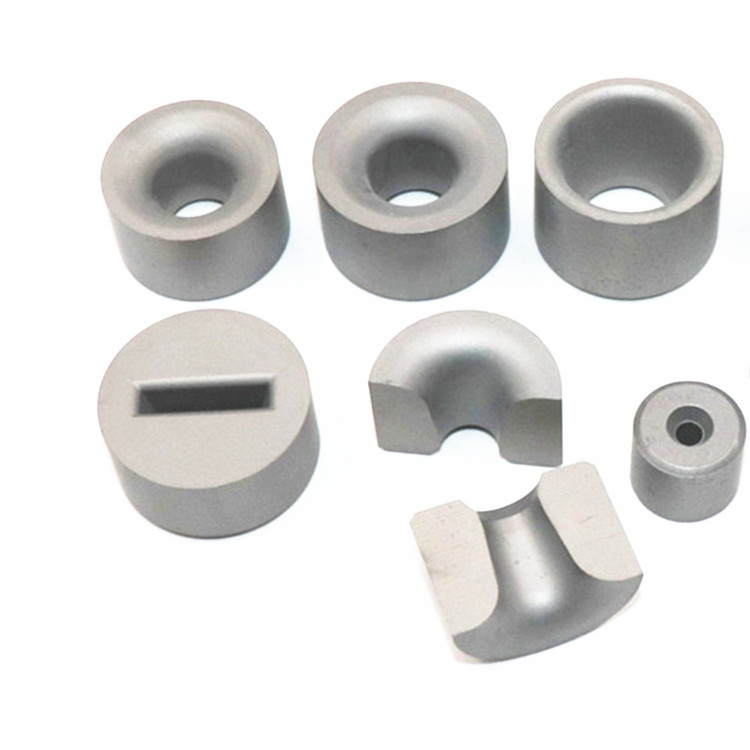

| Tungsten Carbide Cold Forging/heading Dies | |||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. | |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. | |

| GT55 | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. | |

YG22C Tungsten Carbide Cold Heading Dies , Cemented Carbide Pellets For Fastener Tool

Get high-quality YG22C Tungsten Carbide Cold Heading Dies and Cemented Carbide Pellets for Fastener Tool from our factory. Trusted manufacturer of precision tools.

Request a QuotePRODUCTS DETAILS

Hot Products

High quality and competitive price TC rings/tungsten carbide roller

Wholesale Carbide Tungsten Drawing Dies

Best Selling Tungsten Carbide Rollers Carbide Roller with good wear resistance

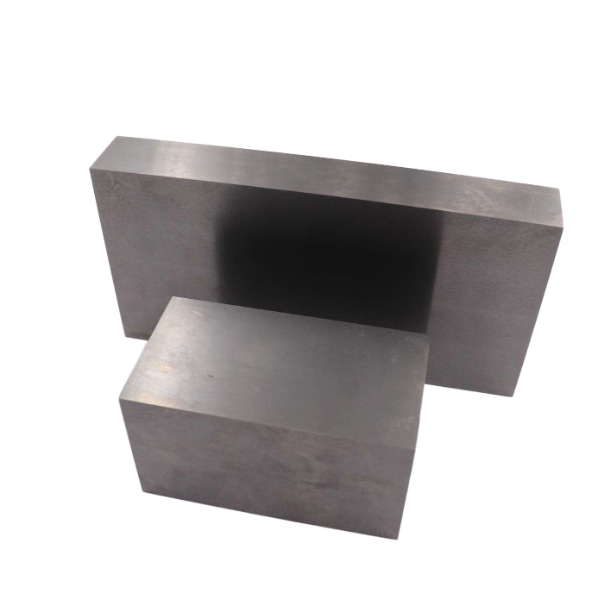

High quality Cemented carbide strips/ Tungsten carbide strips

15% Cobalt YG15 Tungsten Carbide Cold Heading Dies For Cold Heading Machine

YG15 YGH30 Tungsten Carbide Ring Roller for Wire Rod Mills

Factory price high specific gravity tungsten alloy High-density tungsten carbide dies

Customized heat resistant tungsten carbide roller ring in heat treatment furnace

Cemented Tungsten Carbide Cold Heading Pellets For Colding Heading Dies

Wholesale YG8 Tungsten Carbide Wear-Resistance Parts

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours