Screw with Coating for Enhanced Performance - Find Out More

By:Admin

Established in 1995, the company has always been dedicated to providing top-notch products and excellent customer service. They have a team of experienced professionals who are constantly working on research and development to come up with new and improved products.

The Screw Second Punch With Coating is the latest addition to their product line. It is designed to provide superior performance and efficiency in a wide range of applications. The coating on the screw and punch ensures corrosion resistance and longevity, making it an ideal choice for outdoor and industrial use.

One of the key features of the Screw Second Punch With Coating is its precision engineering. The company uses advanced technology and state-of-the-art machinery to manufacture these products with strict quality control measures. This ensures that each and every screw and punch meets the highest standards and specifications.

The coating on the screw and punch not only provides protection against corrosion, but also enhances its overall performance. It reduces friction and wear, resulting in smoother operation and extended lifespan of the product. This is particularly beneficial in heavy-duty applications where the equipment is subjected to harsh conditions.

Furthermore, the Screw Second Punch With Coating is designed for easy installation and maintenance. It comes in various sizes and specifications to cater to different requirements. Whether it's for construction, automotive, or any other industry, the company ensures that their products are versatile and adaptable to various applications.

In addition to the product's technical specifications, the company also emphasizes the importance of sustainability. They use eco-friendly materials and processes in the manufacturing of their products, ensuring that they are not only efficient but also environmentally responsible. This resonates well with their customers who are increasingly conscious of their environmental footprint.

The Screw Second Punch With Coating has already gained recognition and praise from various industries. Customers have reported improved performance and durability with the use of this product, which has ultimately led to cost savings and increased productivity.

In conclusion, Screw Second Punch With Coating has set a new benchmark in the industry with their innovative and high-quality product. With a strong focus on precision, durability, and sustainability, the company continues to lead the way in providing top-notch screws and punches for various industries. Their commitment to excellence and customer satisfaction makes them a reliable and trusted partner for businesses around the world.

Company News & Blog

High-Quality Carbide Drawing Die Factory - All You Need to Know

Carbide Drawing Die Factory Leads the Industry in Innovation and QualityCarbide drawing die factory, a leading producer of carbide drawing dies for the wire and cable industry, has been making waves in the industry with its innovative products and commitment to quality. With a rich history in the industry and a dedication to customer satisfaction, the company has become a trusted name in the production of high-quality drawing dies.The company, based in [location], has been in operation for over [number] years, establishing itself as a top producer in the industry. Specializing in the manufacture of carbide drawing dies, the company has gained a reputation for delivering products that meet the highest standards of quality and performance.Known for its commitment to innovation, the company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By continuously improving its manufacturing processes and materials, the company is able to produce drawing dies that are both durable and efficient, meeting the evolving needs of its clients.One of the key factors that sets the company apart from its competitors is its focus on customer satisfaction. The company understands the importance of building strong relationships with its clients and works closely with them to understand their specific needs and requirements. This customer-centric approach has led to the development of custom solutions that address the unique challenges faced by different businesses in the wire and cable industry.In addition to its commitment to quality and innovation, the company also prioritizes sustainability in its operations. By adhering to strict environmental standards and implementing sustainable practices, the company ensures that its manufacturing processes have minimal impact on the environment. This dedication to sustainability has not only helped the company reduce its carbon footprint but has also resonated with its environmentally conscious clients.The company's dedication to quality and innovation has not gone unnoticed, as it has received numerous accolades and certifications for its performance in the industry. These recognitions serve as a testament to the company's unwavering commitment to excellence and its position as a leader in the production of carbide drawing dies.Looking ahead, the company remains focused on its mission to provide high-quality drawing dies that meet the ever-evolving demands of the wire and cable industry. By continuing to invest in research and development and maintaining its customer-centric approach, the company is poised to remain a driving force in the industry for years to come.In conclusion, carbide drawing die factory has established itself as a leading producer of high-quality drawing dies, known for its innovation, commitment to quality, and dedication to customer satisfaction. With a long-standing history in the industry and a focus on sustainability, the company continues to set the bar for excellence in the production of carbide drawing dies, ensuring that it remains a trusted partner for businesses in the wire and cable industry.

Benefits of Cemented Carbide Rolls in Industrial Applications

Cemented Carbide Roll: A Game-Changer In The World Of Industrial ManufacturingIndustrial manufacturing is one of the most important sectors of every economy. It is responsible for the production of goods that are essential to human life, such as automobiles, electronics, and even food products. The manufacturing process involves a wide range of machinery, each of which plays a critical role in ensuring that the products meet the required standards.One of the most crucial components of the machinery used in industrial manufacturing is the roll. A roll is a cylinder-shaped part that helps in shaping and forming materials like sheet metal, plastic, and paper. One of the most advanced rolls in the world of industrial manufacturing is the cemented carbide roll.Introduction to Cemented Carbide RollThe cemented carbide roll is a roll that is widely used in industrial manufacturing. It is hailed as one of the best rolls in terms of performance. The cemented carbide roll is made from tungsten carbide or tungsten carbide and cobalt. These materials make the roll hard and durable, which makes them ideal for use in industrial manufacturing.Cemented carbide rolls are used in various industries, including steel, aluminum, and paper production. They are mostly used in hot rolling mills, where they play a critical role in shaping and forming materials like sheet metal, steel wire, and other similar materials.Features of Cemented Carbide RollOne of the standout features of cemented carbide rolls is their hardness. Cemented carbide rolls are made from materials that have a high melting point, making them extremely resistant to wear, corrosion, and other forms of damage. The rolls can operate in varying temperatures without experiencing any damage.Cemented carbide rolls are also known for their durability. These rolls have a long service life compared to other types of rolls. They can continue working for years without requiring replacement or repairs, which significantly reduces maintenance costs.Another important feature of cemented carbide rolls is their high accuracy. These rolls are made to precision, which ensures that the materials they produce meet the required specifications. The accuracy of cemented carbide rolls results in better quality products, which translates to higher profit margins.Benefits of Cemented Carbide RollCemented carbide rolls have numerous benefits, making them an ideal choice for industrial manufacturing. One of the main benefits of cemented carbide rolls is that they require less frequent replacement and repairs compared to other types of rolls. This significantly reduces maintenance costs, which translates to higher profits for manufacturers.Cemented carbide rolls are also known for their high accuracy, which leads to better quality products. This, in turn, leads to high customer satisfaction and repeat business. Manufacturers that use cemented carbide rolls have a competitive advantage over their competitors who use other types of rolls.Another benefit of cemented carbide rolls is their ability to operate in varying temperatures. These rolls can withstand high temperatures without experiencing any damage, making them ideal for use in hot rolling mills. This ability to operate at high temperatures improves the efficiency of the manufacturing process, which translates to higher productivity and profits.ConclusionIn conclusion, cemented carbide rolls are a game-changer in the world of industrial manufacturing. These rolls are ideal for use in hot rolling mills, where they play a critical role in shaping and forming materials like sheet metal, steel wire, and other similar materials. They are known for their hardness, durability, high accuracy, and ability to operate in varying temperatures. These features and benefits make cemented carbide rolls an ideal choice for manufacturers looking to improve their efficiency, reduce maintenance costs, and produce high-quality products.

Discover the Benefits of Tungsten Carbide Studs in Various Applications

Title: Innovations in Tungsten Carbide Stud Technology Revolutionize Industrial ApplicationsIntroduction:Tungsten Carbide Stud, a pioneering material in the realm of industrial applications, is set to redefine the standards of durability and performance in a wide range of sectors. With its exceptional hardness, heat resistance, and overall versatility, Tungsten Carbide Stud has garnered significant attention from various industries looking to enhance their products and processes. As one of the leading manufacturers in this field, our company strives to push the boundaries of this technology by continuously innovating and improving our products, ensuring optimum efficiency and longevity in demanding environments.Body:1. Understanding Tungsten Carbide Stud and its Properties:Tungsten Carbide Stud, also known as cemented carbide or simply carbide, is a composite material comprising tungsten carbide grains mixed with a binder alloy, typically cobalt. This combination results in a material that exhibits exceptional hardness, strength, and overall wear resistance, surpassing those of traditional materials such as steel. Its outstanding thermal conductivity and resistance to extreme temperatures make it invaluable in heavy-duty applications, including mining, drilling, construction, and machining.2. Enhanced Performance: The incorporation of Tungsten Carbide Stud components in industrial tools and equipment has revolutionized their performance, enabling them to withstand high-stress operations for prolonged durations. Cutting tools, such as drill bits, saw blades, and milling cutters, equipped with Tungsten Carbide Stud inserts, exhibit superior cutting speeds, increased tool life, and excellent chip control. This enhanced performance leads to reduced downtime, increased productivity, and ultimately, cost savings for businesses.3. Mining and Drilling Applications:In the mining and drilling sector, Tungsten Carbide Stud components are crucial in ensuring optimal performance and safety. Due to their exceptional hardness and resistance to abrasion, Tungsten Carbide Stud inserts and tips are commonly used in rock drilling bits, thus improving the efficiency and longevity of drilling operations. Moreover, their ability to withstand extreme pressure and temperature variations makes them ideal for use in downhole drilling tools, where reliability is paramount.4. Construction and Infrastructure:Tungsten Carbide Stud's exceptional wear resistance and toughness lend themselves to applications within the construction and infrastructure industries. With their incorporation into wear parts like cutting edges, bucket teeth, and crushers, these components offer extended service life and reduced maintenance costs. Furthermore, Tungsten Carbide Stud is utilized in tool attachments such as road milling teeth and foundation drilling bits, enabling efficient road construction and deep foundation drilling.5. Machining and Manufacturing:The exceptional hardness of Tungsten Carbide Stud has significant implications for machining and manufacturing processes. Utilizing these materials in metal-cutting inserts, die components, and wear-resistant coatings substantially improves tool life, reduces the need for frequent tool changes, and enhances overall manufacturing efficiency. Additionally, Tungsten Carbide Stud finds applications in metal-forming processes, where its high hardness and compressive strength aid in wire drawing dies, cold heading dies, and extrusion tools.6. Ongoing Innovations:As a leader in the Tungsten Carbide Stud industry, our company remains committed to continuous research and development, harnessing the capabilities of this remarkable material to develop customized solutions that cater to our clients' specific needs. We collaborate closely with industry partners and customers to develop novel applications, improve manufacturing processes, and enhance the durability and efficiency of our products. Our dedication to innovation positions us at the forefront of the industry, enabling us to deliver cutting-edge solutions and establish long-term partnerships.Conclusion:Through the remarkable properties offered by Tungsten Carbide Stud, industries can enhance their performance, reduce costs, and optimize their operations. With its exceptional hardness, heat resistance, and versatility, this composite material has become indispensable in various applications across multiple sectors. As an industry-leading manufacturer, we pride ourselves on continuously pushing the boundaries of Tungsten Carbide Stud technology. By constantly innovating and refining our products, we strive to meet the evolving demands of our clients and contribute to the advancement of global industries.

High-Quality Tungsten Carbide Screws and Nuts Dies for Industrial Applications

[Company name], a leading manufacturer of high-quality industrial tools and components, has introduced a new line of Tungsten Carbide Screws and Nuts Dies to enhance its product offerings. With a strong focus on innovation and quality, the company aims to provide its customers with reliable, durable, and high-performance solutions for all their industrial applications.Tungsten carbide is a remarkably tough and wear-resistant material, making it an ideal choice for demanding mechanical and industrial applications. By utilizing this advanced material in the manufacturing of screws and nuts dies, [company name] is able to deliver products that are exceptionally resilient and long-lasting, even in the harshest operating conditions.The new line of Tungsten Carbide Screws and Nuts Dies offers several key advantages over traditional tooling materials. Firstly, tungsten carbide is significantly harder than steel, which results in improved wear resistance and longer tool life. This means that customers can benefit from reduced tool replacement and maintenance costs, ultimately leading to increased efficiency and cost savings.Additionally, tungsten carbide exhibits excellent thermal and chemical resistance, making it suitable for use in a wide range of applications, including those involving high temperatures, corrosive environments, and abrasive materials. This versatility allows [company name] to offer its customers cutting-edge solutions that meet the most demanding performance requirements.Furthermore, the exceptional hardness and strength of tungsten carbide enable [company name] to precision-engineer screws and nuts dies with intricate designs and tight tolerances. This level of precision ensures consistent and accurate results in manufacturing processes, contributing to overall product quality and reliability.As a company dedicated to providing comprehensive solutions to its customers, [company name] offers a wide range of Tungsten Carbide Screws and Nuts Dies to accommodate various industry needs. Whether it is for metalworking, plastic injection molding, extrusion, or any other application, customers can rely on [company name] to deliver high-quality, customized tooling solutions that meet their specific requirements.In addition to the new product line, [company name] continues to uphold its commitment to exceptional customer service and technical support. The company's team of experts is readily available to assist customers in selecting the most suitable screws and nuts dies for their applications and to provide guidance on tooling optimization, maintenance, and troubleshooting.Furthermore, [company name] emphasizes the importance of continuous improvement and innovation in its operations. The introduction of Tungsten Carbide Screws and Nuts Dies is a testament to the company's dedication to staying at the forefront of technological advancements and meeting the evolving needs of the industry.With its extensive experience, technical expertise, and unwavering dedication to quality, [company name] has established itself as a trusted partner for businesses across various sectors. The introduction of Tungsten Carbide Screws and Nuts Dies further solidifies the company's position as a leading provider of high-performance industrial tools and components.In conclusion, the launch of the new Tungsten Carbide Screws and Nuts Dies underscores [company name]'s ongoing commitment to delivering innovative, reliable, and high-quality solutions to its customers. By leveraging the exceptional properties of tungsten carbide, [company name] aims to empower businesses with the tools they need to enhance productivity, reduce costs, and achieve superior performance in their operations. The company's dedication to excellence, combined with its customer-centric approach, continues to set [company name] apart as a preferred supplier of industrial tooling solutions.

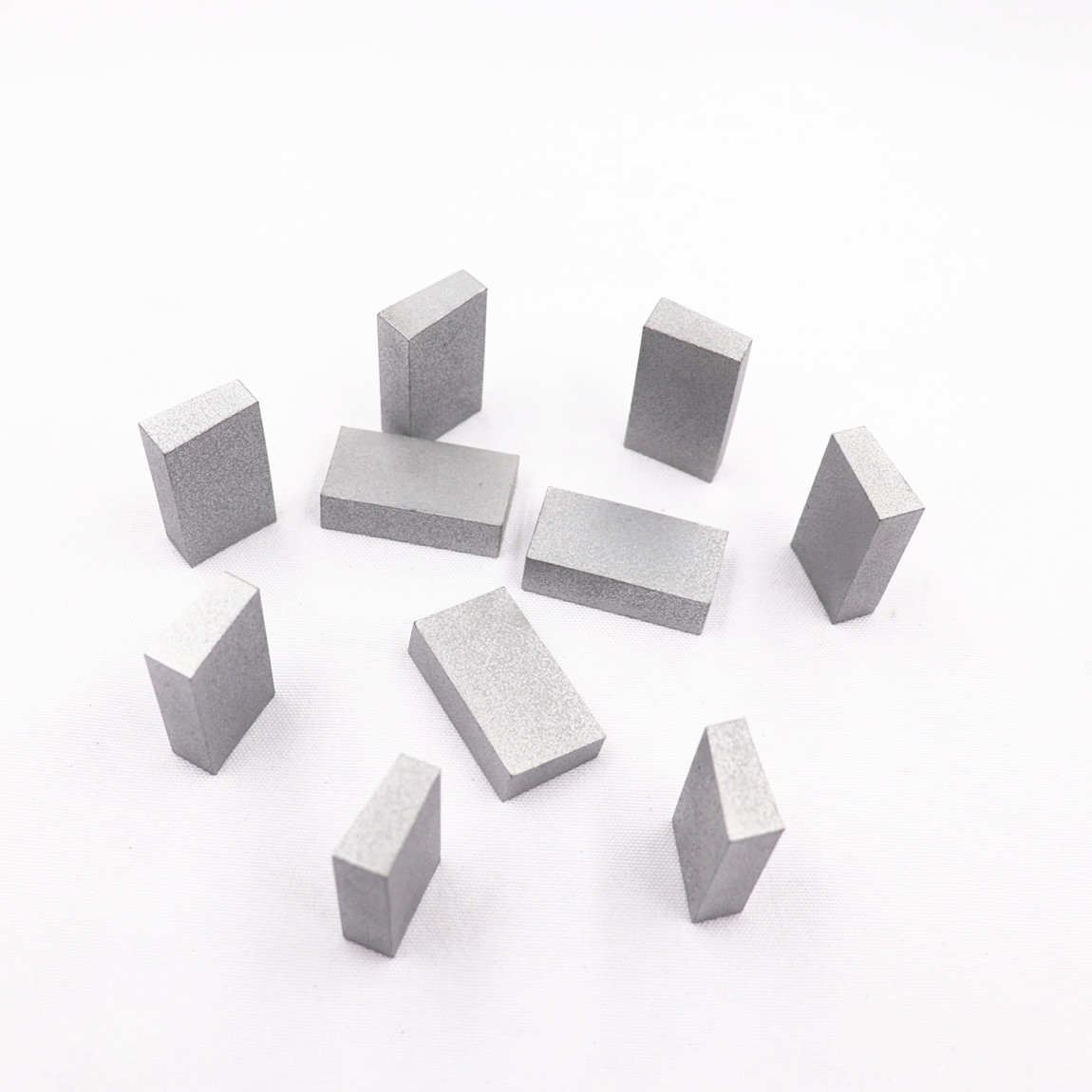

Cemented Carbide Pallets: A Leading Solution for Durable Industrial Applications

Title: Innovative Cemented Carbide Pallets Revolutionize Industrial ApplicationsIntroduction:In the constantly evolving landscape of industrial tools and materials, cemented carbide pallets have emerged as a game-changer. These exceptionally durable and versatile tools have gained immense popularity for their ability to withstand extreme conditions, enhance productivity, and improve manufacturing processes across various industries.Company Introduction:{Company Name} is a renowned leader in the development and production of cemented carbide pallets. With years of experience and a proven track record of delivering high-quality solutions, {Company Name} has established itself as a trusted provider of innovative tools for diverse industrial applications. Combining cutting-edge technology, meticulous research, and a commitment to excellence, {Company Name} continues to set new benchmarks in the manufacturing industry.[Paragraph 1 - Cemented Carbide Pallets Overview]Cemented carbide pallets, also known as hard metal pallets, are manufactured from a combination of metal carbide and binder metals. This unique composition results in a superior material that is incredibly resistant to wear, corrosion, and heat. The exceptional strength and hardness of these pallets make them ideal for use in a wide range of industrial applications where traditional tools fall short.[Paragraph 2 - Unmatched Durability]One of the key features that sets cemented carbide pallets apart from conventional tools is their unparalleled durability. Thanks to their exceptional hardness, these pallets can withstand extreme conditions and abrasive materials without losing their effectiveness. They can endure high temperatures, heavy impacts, pressure, and exposure to corrosive agents, ensuring robust performance and prolonged tool life.[Paragraph 3 - Enhanced Productivity]With cemented carbide pallets, industries can optimize their efficiency and maximize productivity. The superior hardness and wear resistance of these pallets eliminate the need for frequent tool changes, reducing downtime and increasing operational speed. This results in improved manufacturing processes and significant cost savings, making cemented carbide pallets a preferred choice for various industries, including automotive, aerospace, mining, and manufacturing.[Paragraph 4 - Versatile Applications]The versatility of cemented carbide pallets is another aspect that makes them invaluable to industries. These pallets are available in a range of shapes and sizes, tailored to meet the specific requirements of different machining operations. From cutting, drilling, and shaping to grinding and milling, cemented carbide pallets can handle a variety of tasks with precision. Their exceptional performance in tooling applications enables industries to achieve greater accuracy and finer finishes.[Paragraph 5 - Sustainability]In addition to their remarkable performance, cemented carbide pallets contribute to sustainable manufacturing. The long lifespan of these pallets reduces waste generated from frequent tool replacements, minimizing the environmental impact. Furthermore, their improved efficiency and reduced energy consumption significantly lower carbon emissions during the manufacturing process. By opting for cemented carbide pallets, industries can align their operations with sustainable practices and contribute to a greener future.[Paragraph 6 - Ongoing research and development]{Company Name} recognizes the importance of continuous innovation and investment in research and development. Committed to staying ahead of the curve, the company consistently explores new materials, advanced manufacturing techniques, and improved designs for cemented carbide pallets. This ensures that their customers always have access to the latest technologies and solutions to address their evolving needs and challenges.[Paragraph 7 - Conclusion]Cemented carbide pallets have revolutionized the industrial landscape, offering exceptional durability, enhanced productivity, versatility, and sustainability. With {Company Name} leading the way in their development and production, industries can embrace these innovative tools to optimize their processes and achieve unprecedented results. As the demand for reliable and high-performance tools continues to grow, cemented carbide pallets are set to become an indispensable asset across a myriad of industries, driving progress and shaping the future of manufacturing.

The Advantages and Applications of Cemented Carbide YG15: A Comprehensive Guide

In recent news, a cemented carbide manufacturer has made significant progress in the development of their product - YG15 (brand name removed). The YG15 cemented carbide is a highly durable and wear-resistant material that is widely used in the manufacturing industry for various components.The YG15 cemented carbide is an alloy made from a combination of tungsten carbide and cobalt powder, which is blended together and then subjected to a sintering process to produce a solid, hard-wearing material. The YG15 cemented carbide has been tested against various types of wear and tear, including abrasion, corrosion, and impact, and has been found to be highly resistant against all forms of wear and tear.One of the unique features of YG15 cemented carbide is its excellent resistance to abrasion. Abrasion is a type of wear that is caused by the rubbing or scraping of two surfaces against each other, which can result in the surface becoming rough and dull. This type of wear can be particularly problematic in industrial applications, where components are subjected to constant abrasion, leading to high levels of wear and tear.YG15 cemented carbide is also highly resistant to corrosion, which is the process of materials gradually deteriorating due to exposure to environmental factors such as moisture, temperature, and chemicals. This makes YG15 cemented carbide an ideal material for use in harsh environments, such as those found in the oil and gas industry, where components are exposed to corrosive fluids.In addition to its excellent resistance to wear and tear, YG15 cemented carbide is also known for its high strength and durability. This makes it an ideal material for use in high-stress applications, such as those found in the aerospace and automotive industries.One of the key benefits of YG15 cemented carbide is its ability to be shaped and formed into various components. This makes it a versatile material that can be used to manufacture a wide range of products, including cutting tools, wear parts, and industrial machinery components.The manufacturer of YG15 cemented carbide prides itself on producing a high-quality product that is consistently reliable and meets the needs of its customers. The company has invested heavily in research and development to ensure that its products are at the forefront of technological advancements.In addition to providing high-quality products, the manufacturer of YG15 cemented carbide places a great deal of emphasis on customer service and support. This includes providing expert advice on product selection, as well as offering technical support and troubleshooting services to help customers get the most out of their products.Overall, YG15 cemented carbide is a highly durable and wear-resistant material that is widely used in the manufacturing industry for various components. Its excellent resistance to abrasion and corrosion, as well as its high strength and durability, make it an ideal material for use in high-stress applications. With its consistent reliability and commitment to customer service and support, the manufacturer of YG15 cemented carbide is a trusted and respected name in the industry.

Discover the Superior Performance of Tungsten Carbide YG15

Title: Revolutionary Tungsten Carbide Unveiled by Prominent ManufacturerIntroduction: In a groundbreaking development within the industrial sector, a prominent manufacturer, renowned for its cutting-edge innovations, has unveiled a new revolutionary material – YG15 Tungsten Carbide. This remarkable achievement promises to redefine the manufacturing landscape by providing unparalleled strength, durability, and versatility.1. Understanding YG15 Tungsten Carbide:Tungsten Carbide has long been hailed as a superior material due to its exceptional qualities. YG15 Tungsten Carbide, specifically, refers to a unique composition of the material that offers enhanced performance for numerous applications. This variant incorporates 15% Cobalt, imparting superior hardness, strength, and wear resistance, making it ideal for a wide range of industries.2. Superior Strength and Durability:With an outstanding hardness rating, YG15 Tungsten Carbide exhibits remarkable strength, especially when compared to traditional metals. This material is twice as hard as steel and almost four times harder than titanium. Its exceptional durability ensures that it withstands extreme wear and tear, making it suitable for cutting tools, wear-resistant components, and various mechanical applications.3. Versatile Applications:YG15 Tungsten Carbide's exceptional properties have led to its widespread application across diverse industries. This revolutionary material is extensively used in the manufacturing of cutting tools, such as drill bits, milling cutters, and reamers. Its impressive hardness and resistance to high temperatures also make it ideal for use in the aerospace industry, where it functions as a vital component in turbines and jet engine nozzles.4. Revolutionizing Mining and Construction:Another area where YG15 Tungsten Carbide has made a significant impact is in the mining and construction sectors. Due to its unparalleled hardness, resilience, and resistance to abrasive environments, it has become the material of choice for drilling bits, excavation tools, and wear-resistant components in heavy machinery. This enables efficient operations and increased productivity while reducing maintenance costs.5. Applications in Electronics and Wearables:The electronics and wearables industry has also embraced YG15 Tungsten Carbide due to its unique properties. The material's excellent corrosion resistance means it can withstand harsh conditions. Consequently, it finds application in the production of electrical connectors, circuit breakers, and various other electronic components, ensuring high performance and reliability.6. Sustainability and Environmental Benefits:Apart from its remarkable performance, YG15 Tungsten Carbide also contributes to sustainable manufacturing practices. Its durability and longevity minimize the need for frequent replacement, significantly reducing waste production. Additionally, the material does not contain any hazardous substances, making it environmentally friendly and safe for both users and the environment.Conclusion:The introduction of YG15 Tungsten Carbide by this prominent manufacturer represents a significant milestone in the materials industry. Boasting unparalleled strength, durability, and versatility, this revolutionary material is set to revolutionize various sectors, including manufacturing, mining, construction, electronics, and more. With its exceptional properties and sustainable benefits, YG15 Tungsten Carbide is poised to redefine standards and play a pivotal role in shaping the future of industrial manufacturing.

Tungsten Carbide Production Skyrockets in China: Discover the Latest Updates and Trends

Title: China's Tungsten Carbide Industry Poised for Steady GrowthIntroduction:China has been a global leader in various industrial sectors, and its thriving tungsten carbide industry is no exception. Tungsten carbide, a versatile and highly valuable material, is used extensively in sectors such as manufacturing, construction, mining, and aerospace due to its exceptional hardness and wear resistance properties. As China continues its progression as an industrial powerhouse, the demand for tungsten carbide products is expected to soar. In this article, we delve into the flourishing tungsten carbide industry in China, its market prospects, and its contribution to the country's economic growth.Overview of Tungsten Carbide China:Tungsten carbide China has emerged as one of the leading suppliers of this crucial material globally. Companies such as [Company name] have established themselves as the key players in the industry, consistently delivering high-quality tungsten carbide products to meet the growing demands of both domestic and international markets.With state-of-the-art manufacturing facilities and advanced research and development capabilities, industry leaders in China have been able to maintain a competitive edge, offering a wide range of tungsten carbide products and solutions tailored to specific customer requirements.Growing Demand and Expanding Markets:The increasing application of tungsten carbide in various industries has been driving the demand for this specialized material. From cutting tools and wear parts to drilling and mining equipment, tungsten carbide plays a pivotal role in enhancing productivity and efficiency across industries.China's rapid urbanization and infrastructure development have fueled the demand for tungsten carbide in construction machinery and tools. As the government continues to invest heavily in transportation infrastructure, including railways and highways, the demand for tougher and wear-resistant tools will increase further.Moreover, the mining sector, which plays a crucial role in China's economy, relies on tungsten carbide for its drilling and cutting operations. The material's strength and durability make it ideal for mining tools, enabling efficient and safe exploration of mineral resources.In addition, the aerospace industry is another significant consumer of tungsten carbide in China. The material's exceptional hardness and capability to withstand high temperatures have made it indispensable in aircraft manufacturing. China's burgeoning aerospace sector is expected to drive the demand for tungsten carbide even higher.Government Support and Technological Advancements:China's government has recognized the importance of the tungsten carbide industry and has provided support to foster its growth. Favorable policies, tax incentives, and investments in research and development have enabled domestic companies to develop innovative products and expand their market reach. Moreover, the establishment of specialized tungsten carbide research institutions has further boosted technological advancements in this field.Environmental Concerns and Sustainable Practices:As the tungsten carbide industry grows, so does the focus on sustainable practices and environmental stewardship. China's leading suppliers have been actively adopting advancements in manufacturing processes to minimize waste, reduce energy consumption, and recycle materials. The industry is dedicated to balancing economic growth with sustainable development, ensuring a greener and more eco-friendly future.Exports and Global Market Expansion:China's tungsten carbide industry has experienced significant growth in exports, catering to the increasing demand from international markets. With its competitive pricing, robust quality control systems, and efficient logistics infrastructure, China has established itself as a reliable supplier of tungsten carbide products worldwide. This expansion into global markets has not only bolstered the country's economy but also enhanced China's reputation as a technologically advanced manufacturer.Conclusion:China's Tungsten Carbide industry, led by companies such as [Company name], is poised for steady growth in the coming years. With increasing demands from various sectors, coupled with government support, technological advancements, and a commitment to sustainable practices, China is set to solidify its position as a global leader in the production and export of tungsten carbide products. As this industry continues to thrive, it will contribute significantly to China's economic growth and reinforce its industry dominance on the global stage.

Top 5 Durable and Efficient Tools for Your Workshop

[Company Name] Introduces Superior Tungsten Carbide Tools for Enhanced Efficiency and Productivity[City name, Date] - [Company Name], a leading manufacturer of cutting-edge industrial tools, has unveiled its latest line of premium-quality tungsten carbide tools. Leveraging its extensive expertise in tool manufacturing, the company aims to cater to the increasing demand for high-performance tools in diverse industries.With a strong commitment to delivering innovative solutions, [Company Name] has invested significant resources into research and development, resulting in the creation of state-of-the-art tungsten carbide tools. These tools are designed to not only enhance efficiency and productivity but also deliver unparalleled precision and durability.Tungsten carbide is a compound known for its exceptional hardness and resistance to wear and tear, making it an ideal material for tool manufacturing. By combining tungsten carbide with other sophisticated alloys, [Company Name] has created a wide range of tools suitable for various applications, including cutting, drilling, grinding, and milling.One of the key highlights of [Company Name]'s tungsten carbide tools is their exceptional cutting-edge retention. Unlike conventional tools, which often need frequent sharpening, these tools possess remarkable wear resistance, extending their lifespan and reducing downtime significantly. This advantage allows businesses to optimize their operations and streamline their production processes.Additionally, the advanced composition of [Company Name]'s tungsten carbide tools provides increased heat resistance, allowing for higher operating speeds. This feature leads to faster production cycles and higher throughput, resulting in improved overall efficiency. Furthermore, the enhanced heat resistance decreases the risk of tool deformation, ensuring consistent and reliable performance over prolonged periods.The versatility of [Company Name]'s tungsten carbide tools enables them to cater to a wide range of industries, including automotive, aerospace, construction, and mining. From precision cutting tools used in the automotive industry to heavy-duty tools required for mining operations, [Company Name] offers a comprehensive selection to meet various industrial needs.In addition to their durability and reliability, [Company Name]'s tungsten carbide tools are also designed for ease of use and operator comfort. Ergonomics are considered during the tool design process, ensuring that workers can handle the tools efficiently and safely for prolonged periods.To meet diverse customer requirements, [Company Name] offers customization options for its tungsten carbide tools. The company's team of experienced engineers works closely with clients to understand their specific needs and develops tailor-made solutions. This personalized approach sets [Company Name] apart from its competitors, as it strives to deliver customer-centric products and services.Furthermore, [Company Name] maintains a robust distribution network, ensuring that its tungsten carbide tools are readily available to customers worldwide. Alongside providing high-quality tools, the company offers comprehensive technical support and after-sales services to ensure customer satisfaction at every stage.Speaking about the latest product line, [Name], [Company Name]'s spokesperson, highlighted the company's commitment to innovation and customer success. He stated, "We are excited to introduce our new range of tungsten carbide tools that reflect our dedication to providing cutting-edge solutions to our customers. Through continuous research and development, we have created tools that not only meet but exceed industry standards, enabling our clients to achieve enhanced productivity and efficiency."With its innovative range of tungsten carbide tools, [Company Name] is poised to revolutionize the industrial tooling landscape. As businesses increasingly recognize the importance of utilizing high-performance tools, [Company Name] stands ready to meet their needs, ensuring they stay ahead in today's competitive market.About [Company Name]:[Company Name] is a renowned manufacturer of industrial tools with a strong focus on innovation and customer satisfaction. With a global presence, the company serves diverse industries, delivering cutting-edge solutions and exceptional customer service. Through continuous research and development, [Company Name] aims to set new standards in the tool manufacturing industry.

Durable Tungsten Carbide Sleeve Bushing for High-Performance Machinery

Tungsten Carbide Sleeve Bushing: The Future of High-Quality ManufacturingIn the world of modern manufacturing, there is little room for error. Every component, every piece, and every part must be meticulously designed and manufactured to meet exacting standards. That's where tungsten carbide comes in.Tungsten carbide is a material that has been used for many years to create high-quality machine parts. Its hardness, durability, and resistance to wear make it an ideal choice for a wide range of applications. One of the most popular uses for tungsten carbide is in the manufacturing of sleeve bushings, which are used as bearings in industrial machinery.The benefits of tungsten carbide sleeve bushings are clear. They provide excellent wear resistance and can withstand high impact loads and harsh environments. They are also highly corrosion-resistant, making them ideal for use in chemical or acidic environments. Additionally, they have a longer lifespan than other types of bushings, which reduces maintenance costs and improves overall efficiency.One company that has been at the forefront of manufacturing tungsten carbide sleeve bushings is the world-renowned brand name. With decades of experience in the manufacturing industry, they have become a trusted supplier of tungsten carbide products to businesses across a wide range of industries.Their tungsten carbide sleeve bushings are made using advanced manufacturing techniques and state-of-the-art equipment, ensuring that every product meets the high standards of quality and performance that their customers demand. Each bushing is carefully designed and engineered to deliver maximum performance and longevity, making it an integral part of any industrial machinery.But what sets this company apart from the competition is their commitment to customer service. They work closely with their clients to ensure that every product meets their specific needs and requirements. They offer a wide range of customization options, including different sizes, shapes, and materials, to ensure that their products are the perfect fit for their clients' machinery.Furthermore, they are constantly innovating, developing new products that utilize the latest in tungsten carbide technology. They are committed to staying ahead of the curve and providing their customers with the most advanced products on the market. This dedication to innovation has made them a leader in the industry and a trusted supplier to businesses around the world.In conclusion, tungsten carbide sleeve bushings are an essential component of modern manufacturing. They offer unparalleled durability, wear resistance, and performance, making them ideal for a wide range of industrial applications. And with the world-renowned company's commitment to quality, innovation, and customer service, businesses can be confident that they are getting the very best in tungsten carbide products.