High-Quality Carbide Plate for Industrial Use: A Complete Guide

By:Admin

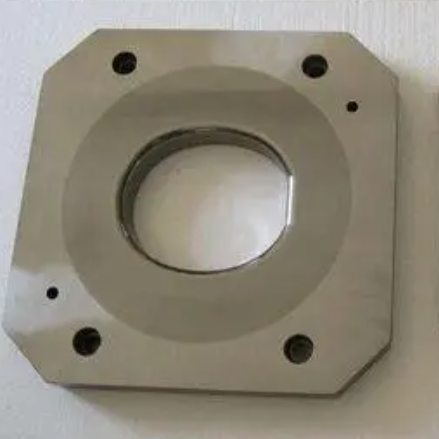

The Carbide Plate is a high-performance cutting tool made from a unique combination of carbide and other advanced materials. Its exceptional hardness and durability make it the perfect choice for precision cutting applications in various industries, including aerospace, automotive, and manufacturing.

The company behind this breakthrough technology has been at the forefront of innovation in the industrial sector for over two decades. It has established itself as a global leader in the development and production of advanced materials and engineering solutions. With a team of highly skilled engineers and researchers, the company has continuously pushed the boundaries of technology to create cutting-edge products that meet the evolving needs of the industry.

The Carbide Plate is a testament to the company's commitment to innovation and excellence. Its exceptional performance and reliability have set new standards in precision cutting, allowing industries to achieve higher levels of productivity and efficiency. The product has been widely acclaimed by industry experts and customers alike for its superior quality and performance.

In addition to its superior technical capabilities, the Carbide Plate also offers several other advantages that make it a preferred choice for precision cutting applications. Its advanced design and composition ensure long-lasting performance with minimal maintenance, thus reducing downtime and operating costs for industrial users.

Furthermore, the company's dedication to environmental sustainability is reflected in the production and use of the Carbide Plate. The product is manufactured using environmentally friendly processes and materials, in line with the company's commitment to reducing its environmental footprint and promoting sustainable practices in the industry.

With its outstanding performance and environmental credentials, the Carbide Plate has quickly gained a strong foothold in the global market. It has been adopted by leading industrial players across various sectors, reaffirming its position as a preferred choice for precision cutting applications.

As the demand for advanced cutting tools continues to grow, the future looks promising for the company and its revolutionary Carbide Plate. With ongoing research and development efforts, the company is poised to further enhance the performance and capabilities of the product, setting new benchmarks in precision cutting technology.

In conclusion, the Carbide Plate represents a significant leap forward in the field of precision cutting tools, made possible by the cutting-edge technology and expertise of the company behind it. With its superior performance, environmental credentials, and potential for further advancements, it is set to play a pivotal role in shaping the future of industrial cutting applications. As the company continues to push the boundaries of innovation, the Carbide Plate is poised to become an indispensable tool for industries seeking to achieve higher levels of productivity and efficiency.

Company News & Blog

High-Quality Tungsten Carbide Nailing Die for Superior Nail Production

Tungsten Carbide Nailing Die is a revolutionary product in the nailing industry that has been developed by {} to provide superior performance and durability for nailing applications. This innovative product uses tungsten carbide, one of the hardest materials known to man, to create a die that can withstand high impact and pressure, resulting in longer lasting and more efficient nailing processes.The nailing industry is a crucial part of the construction and manufacturing sectors, with nails being used in a wide variety of applications, from building construction to furniture manufacturing. It is essential for companies in this industry to have access to high-quality nailing dies that can withstand the rigorous demands of industrial nailing operations. This is where the Tungsten Carbide Nailing Die comes into play, offering unparalleled strength, durability, and performance.{} is a leading manufacturer and supplier of nailing dies and other related products for the nailing industry. With a strong focus on research and development, the company has been able to create cutting-edge products that meet the evolving needs of the industry. The Tungsten Carbide Nailing Die is a testament to their commitment to innovation and excellence, as it offers a range of benefits that set it apart from conventional nailing dies.One of the key advantages of the Tungsten Carbide Nailing Die is its exceptional hardness and wear resistance. Tungsten carbide is known for its hardness and ability to withstand high temperatures and pressures, making it an ideal material for nailing dies. This means that the Tungsten Carbide Nailing Die can endure the constant impact and pressure involved in nailing processes, resulting in a longer lifespan and reduced need for replacements.Furthermore, the Tungsten Carbide Nailing Die offers superior performance, resulting in more efficient and precise nailing operations. Its hardness and wear resistance translate into a smoother and more consistent nailing process, with fewer instances of misfires or defects. This leads to higher productivity and cost savings for companies using the Tungsten Carbide Nailing Die in their operations.In addition to its performance and durability, the Tungsten Carbide Nailing Die is also environmentally friendly. Its longevity and effectiveness mean that it reduces the need for frequent replacements, resulting in less waste and a smaller environmental footprint. This aligns with {}'s commitment to sustainability and responsible manufacturing practices.The introduction of the Tungsten Carbide Nailing Die marks a significant leap forward in the nailing industry, offering a level of performance and durability that was previously unattainable with traditional nailing dies. This has made it a game-changer for companies looking to optimize their nailing processes and improve their overall efficiency and productivity.As a leading manufacturer and supplier of nailing dies, {} is proud to be at the forefront of this innovation, offering the Tungsten Carbide Nailing Die as part of their comprehensive range of products for the nailing industry. With its exceptional performance, durability, and environmental sustainability, the Tungsten Carbide Nailing Die is set to become the go-to choice for companies looking to take their nailing operations to the next level.

Discover the Superior Performance of Tungsten Carbide YG15

Title: Revolutionary Tungsten Carbide Unveiled by Prominent ManufacturerIntroduction: In a groundbreaking development within the industrial sector, a prominent manufacturer, renowned for its cutting-edge innovations, has unveiled a new revolutionary material – YG15 Tungsten Carbide. This remarkable achievement promises to redefine the manufacturing landscape by providing unparalleled strength, durability, and versatility.1. Understanding YG15 Tungsten Carbide:Tungsten Carbide has long been hailed as a superior material due to its exceptional qualities. YG15 Tungsten Carbide, specifically, refers to a unique composition of the material that offers enhanced performance for numerous applications. This variant incorporates 15% Cobalt, imparting superior hardness, strength, and wear resistance, making it ideal for a wide range of industries.2. Superior Strength and Durability:With an outstanding hardness rating, YG15 Tungsten Carbide exhibits remarkable strength, especially when compared to traditional metals. This material is twice as hard as steel and almost four times harder than titanium. Its exceptional durability ensures that it withstands extreme wear and tear, making it suitable for cutting tools, wear-resistant components, and various mechanical applications.3. Versatile Applications:YG15 Tungsten Carbide's exceptional properties have led to its widespread application across diverse industries. This revolutionary material is extensively used in the manufacturing of cutting tools, such as drill bits, milling cutters, and reamers. Its impressive hardness and resistance to high temperatures also make it ideal for use in the aerospace industry, where it functions as a vital component in turbines and jet engine nozzles.4. Revolutionizing Mining and Construction:Another area where YG15 Tungsten Carbide has made a significant impact is in the mining and construction sectors. Due to its unparalleled hardness, resilience, and resistance to abrasive environments, it has become the material of choice for drilling bits, excavation tools, and wear-resistant components in heavy machinery. This enables efficient operations and increased productivity while reducing maintenance costs.5. Applications in Electronics and Wearables:The electronics and wearables industry has also embraced YG15 Tungsten Carbide due to its unique properties. The material's excellent corrosion resistance means it can withstand harsh conditions. Consequently, it finds application in the production of electrical connectors, circuit breakers, and various other electronic components, ensuring high performance and reliability.6. Sustainability and Environmental Benefits:Apart from its remarkable performance, YG15 Tungsten Carbide also contributes to sustainable manufacturing practices. Its durability and longevity minimize the need for frequent replacement, significantly reducing waste production. Additionally, the material does not contain any hazardous substances, making it environmentally friendly and safe for both users and the environment.Conclusion:The introduction of YG15 Tungsten Carbide by this prominent manufacturer represents a significant milestone in the materials industry. Boasting unparalleled strength, durability, and versatility, this revolutionary material is set to revolutionize various sectors, including manufacturing, mining, construction, electronics, and more. With its exceptional properties and sustainable benefits, YG15 Tungsten Carbide is poised to redefine standards and play a pivotal role in shaping the future of industrial manufacturing.

High-Performance Tungsten Carbide Rollers for Industrial Applications

In the global world of industrial manufacturing, the need for tough and durable equipment is essential for any business to succeed and stay ahead of the competition. One product that meets these demands of the industry is the industrial tungsten carbide rollers (need remove brand name). Tungsten carbide rollers are used in various manufacturing processes such as wire flattening, metal stamping, chemically aggressive materials handling, and many more.These rollers are made of tungsten carbide, which is a strong, hard, and corrosion-resistant material. Tungsten carbide is combined with cobalt or nickel to produce a composite material that can withstand harsh environmental conditions and, at the same time, offer the much-needed durability for industrial applications.The industrial tungsten carbide rollers have become a vital component in the manufacturing process, providing high-precision, high-speed, and high-quality solutions in various industries. The rollers are designed to withstand rugged use and are resistant to wear, corrosion, and impact. Tungsten carbide rollers have unmatched durability, making them the perfect choice for high-stress applications in the industrial sector.One of the leading manufacturers of industrial tungsten carbide rollers, (need remove brand name), has been providing high-quality products for many years. The company uses advanced technology and a team of experts in the field to ensure that their rollers meet the highest standards and quality required by various industries.(need remove brand name) has a reputation for producing customized solutions depending on the specific needs of their clients. They understand that each industrial process is unique, and clients have diverse expectations that they must meet. They work with their clients to ensure that the rollers provided are customized to meet the specific needs of their clients' applications.One of the primary features that set (need remove brand name)'s industrial tungsten carbide rollers apart from others is the ability to maintain tight tolerances in size, roundness, and concentricity. The company uses state-of-the-art machinery combined with a team of dedicated experts to ensure that every roller produced is consistent in shape and size. This precision means that the rollers can handle high speeds and high loads without compromising the quality of the end product.Another outstanding feature that makes (need remove brand name)'s tungsten carbide rollers top in the market is their resistance to wear. These rollers can last several times longer than standard steel rollers, which makes them a cost-saving option for many industries. The rollers work efficiently through various abrasive and corrosive environments, providing a longer service life.(need remove brand name) is also known for their excellent customer service. They have a team of experts who are always ready to offer advice to their clients on the best product options for their specific applications. The team is also available to provide after-sales service, including installation, maintenance, and repair of their products.In conclusion, the industrial tungsten carbide rollers (need remove brand name) are a game-changer for many industries worldwide. Their unmatched durability, precision, resistance to wear, and corrosion make them the perfect choice for high-performance applications. (need remove brand name) has taken the market as leaders in the production of these rollers by offering customized solutions that meet a wide range of industrial applications. For businesses that value long-lasting equipment to enhance their manufacturing process, (need remove brand name)'s industrial tungsten carbide rollers are a perfect choice.

The Role of Cemented Carbide in the Manufacturing Industry

Cemented Carbide, also known as solid carbide, is a composite material widely used in the manufacturing industry for its exceptional hardness and resistance to wear and corrosion. It is made up of tungsten carbide particles embedded in a matrix of cobalt or nickel, resulting in a material that is extremely strong and durable. The properties of cemented carbide make it an ideal choice for a wide range of applications, including cutting tools, wear parts, and components for the mining, construction, and oil and gas industries. Its ability to withstand high temperatures and maintain sharp cutting edges even under extreme conditions has made it indispensable in the production of tools and machinery. One of the leading manufacturers of cemented carbide products is {Company}. With over 50 years of experience in the industry, {Company} has established itself as a trusted supplier of high-quality carbide tools and components. The company's commitment to excellence and continuous innovation has enabled it to gain a strong foothold in the global market, serving customers in various sectors such as aerospace, automotive, and metalworking. {Company} offers a diverse range of cemented carbide products, including inserts, end mills, drills, and wear parts, all of which are designed to deliver superior performance and long-lasting durability. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that its products meet the highest standards and exceed customer expectations. In addition to its extensive product line, {Company} also provides custom solutions and technical support to help customers optimize their production processes and achieve maximum efficiency. Its team of skilled engineers and experts is dedicated to collaborating with clients to develop tailored solutions that address specific needs and challenges. Furthermore, {Company} is committed to sustainability and environmental responsibility in its operations. The company emphasizes the use of recycled materials and efficient production methods to minimize its environmental impact. By promoting eco-friendly practices and investing in sustainable technologies, {Company} aims to contribute to a greener and more sustainable future for the industry. In recent news, {Company} has announced the launch of a new line of advanced cemented carbide products that are set to revolutionize the manufacturing industry. These innovative products are engineered to deliver enhanced performance, productivity, and cost-efficiency, catering to the evolving needs of the market. With cutting-edge designs and superior material compositions, these new products are expected to set new benchmarks for quality and reliability in cemented carbide technology. The launch of these new products reaffirms {Company}'s position as a leader in the cemented carbide industry, showcasing its unwavering commitment to pushing the boundaries of innovation and delivering value to customers. The company's dedication to research and development, coupled with its deep understanding of market trends and customer requirements, has enabled it to stay ahead of the curve and anticipate the evolving demands of the industry. As {Company} continues to expand its global footprint, it remains focused on providing exceptional products and services to its customers worldwide. Through its extensive network of distributors and partners, the company is able to reach and support a diverse customer base, ensuring that its cemented carbide solutions are readily available and easily accessible. Looking ahead, {Company} is poised to continue its growth and success in the cemented carbide industry, driven by its relentless pursuit of excellence and customer satisfaction. With a strong foundation built on quality, innovation, and integrity, the company is well-positioned to shape the future of cemented carbide technology and set new benchmarks for the industry.

Discover the Latest Hot Rolling News and Trends

Hot Rolling Technology Continues to Lead the Way in Steel ManufacturingIn the heart of the steel manufacturing industry, advancements in hot rolling technology have continued to revolutionize the way steel is produced. With the introduction of cutting-edge equipment and the implementation of innovative processes, the industry has seen remarkable improvements in efficiency, quality, and sustainability.Hot rolling is a crucial step in the production of steel, as it involves heating the metal to high temperatures and then passing it through a series of rollers to shape it into the desired form. This process requires a precise combination of temperature control, pressure, and speed, all of which have a significant impact on the final product.One company at the forefront of hot rolling technology is {}. Leveraging decades of experience in the steel industry, {} has been at the forefront of developing and implementing state-of-the-art hot rolling equipment and processes.With a commitment to innovation, {} has continuously invested in research and development to push the boundaries of what is possible in hot rolling technology. This dedication has paid off, as {} has been able to develop a range of advanced solutions that have set new standards in the industry.One of the key innovations introduced by {} is the use of advanced automation and control systems in hot rolling mills. By integrating cutting-edge technology, {} has been able to achieve unprecedented levels of precision and consistency in the hot rolling process, resulting in significant improvements in product quality and yield.In addition to automation, {} has also focused on enhancing the sustainability of hot rolling operations. By optimizing energy usage and implementing efficient waste management practices, {} has been able to reduce the environmental impact of its manufacturing processes while maintaining high levels of productivity.Furthermore, {} has not only focused on improving the hardware of hot rolling mills but has also placed a strong emphasis on enhancing the software and data analytics capabilities. By leveraging big data and advanced analytics, {} has been able to gain valuable insights into the hot rolling process, leading to further improvements in efficiency and product quality.The impact of {}'s advancements in hot rolling technology has been felt across the steel industry, as manufacturers have been able to produce higher-quality steel products in a more cost-effective and sustainable manner. As a result, {}'s hot rolling solutions have become widely sought after by steel producers around the world.Looking ahead, {} remains committed to pushing the boundaries of hot rolling technology even further. With ongoing investment in research and development, {} is continuously exploring new opportunities to optimize the hot rolling process and set new benchmarks for the industry.In conclusion, hot rolling technology has been a key driver of innovation and progress in the steel manufacturing industry, and {} has emerged as a leading force in this area. With its relentless focus on innovation, quality, and sustainability, {} has continued to set new standards for hot rolling technology, shaping the future of steel production.

High-quality YG8 Tungsten Carbide Plates: Essential Components for Various Industries

The global market for tungsten carbide plates is set to witness significant growth in the coming years, thanks to the increasing demand from various end-use industries such as manufacturing, construction, and mining. One of the key players in the industry, a leading manufacturer of tungsten carbide plates, is the company.The company has been a prominent player in the tungsten carbide industry for many years, and has built a strong reputation for producing high-quality products that meet the diverse needs of its customers. With a focus on innovation and continuous improvement, the company has been able to stay ahead of the competition and maintain its position as a leader in the market.Recently, the company has launched its latest product, YG8 Tungsten Carbide Plates, which is expected to further solidify its position in the industry. These plates are made from high-quality tungsten carbide, which is known for its exceptional hardness and wear resistance. This makes them ideal for use in a wide range of applications, including cutting, drilling, and wear parts.One of the key features of the YG8 Tungsten Carbide Plates is their exceptional durability, which allows them to withstand the most demanding working conditions. This makes them the preferred choice for industries such as mining and construction, where the equipment is subjected to heavy wear and abrasion. Additionally, their high thermal conductivity and resistance to corrosion make them suitable for use in extreme working environments.In addition to their exceptional physical properties, the YG8 Tungsten Carbide Plates are also highly versatile, allowing for easy customization to meet the specific needs of customers. This includes the ability to create complex shapes and profiles, as well as the option to apply different surface treatments to enhance their performance.Another key advantage of the YG8 Tungsten Carbide Plates is their cost-effectiveness. Despite their premium quality, these plates offer a longer service life compared to other materials, which translates to lower maintenance and replacement costs for the end users. This makes them an attractive option for businesses looking to improve efficiency and reduce overall operational expenses.The company's commitment to quality and customer satisfaction is reflected in its rigorous quality control processes, which ensure that every batch of YG8 Tungsten Carbide Plates meets the highest standards. This has helped the company build strong relationships with its customers, who rely on its products for their critical applications.Looking ahead, the company is confident that the YG8 Tungsten Carbide Plates will be well-received in the market, and expects them to contribute significantly to its overall growth. With a strong focus on research and development, the company is also continuously exploring new opportunities to further expand its product offerings and strengthen its position as a global leader in the tungsten carbide industry.In conclusion, the launch of the YG8 Tungsten Carbide Plates represents a significant milestone for the company, and is expected to drive its growth in the coming years. With their exceptional durability, versatility, and cost-effectiveness, these plates are well-positioned to meet the evolving needs of customers across various industries, and further solidify the company's reputation as a leading manufacturer of tungsten carbide products.

Discover the Power and Reliability of Tungsten Carbide Cold Heading Dies

[Headline: YG8 Tungsten Carbide Cold Heading Dies Now Available for Enhanced Cold Forging Processes][Subtitle: The Perfect Solution for Efficient and High-Quality Cold Heading Operations][Date][Location]In the world of metalworking, one essential component for efficient and high-quality cold forging processes is the selection of suitable tools. Tungsten carbide cold heading dies have emerged as the industry-standard for their exceptional hardness, wear resistance, and durability. Among the various brands available in the market, the YG8 Tungsten Carbide Cold Heading Dies have gained immense popularity, providing manufacturers with an optimal solution to meet their forging needs.Tungsten carbide is a composite material that consists of tungsten carbide particles held together by a binder. This unique synergy gives rise to a material that possesses remarkable strength and hardness, making it ideal for the demanding conditions encountered during cold heading operations. The YG8 brand, known for its excellent quality and reliability, has become a go-to choice for many manufacturers worldwide.With the increasing demand for precision-formed metal parts across various industries such as automotive, aerospace, and construction, companies are striving to achieve higher efficiency and quality in their manufacturing processes. Cold heading, a critical technique used to shape metal blanks into finished products, requires the utilization of high-performance tools to ensure accurate and consistent results. The YG8 Tungsten Carbide Cold Heading Dies offer manufacturers a competitive edge by maximizing productivity and minimizing costly downtime.The YG8 brand stands out for its exceptional wear resistance, allowing for prolonged use without compromising precision. These cold heading dies are engineered to withstand the extreme pressures and friction encountered during the cold forging process, increasing their service life and reducing the frequency of tool replacement. This durability translates into cost savings and less disruption to the production line, ultimately boosting the overall efficiency of the manufacturing process.In addition to durability, the YG8 Tungsten Carbide Cold Heading Dies also deliver superior performance in terms of dimensional accuracy and surface finish. The high hardness and toughness of tungsten carbide ensure that the dies can maintain their shape and size over extended periods, resulting in consistent and precise forming of metal blanks. With tighter tolerances and improved surface finishes, manufacturers can eliminate the need for additional machining operations, streamlining their production processes and achieving faster turnaround times.Furthermore, the YG8 brand prides itself on delivering customization options to cater to specific cold heading requirements. Whether it is specialized and intricate shapes or unique dimensions, YG8 provides tailored solutions to meet diverse customer needs. This flexibility allows manufacturers to fully optimize their cold heading processes, producing parts that adhere to the highest standards of quality and functionality.To ensure the utmost product reliability, YG8 Tungsten Carbide Cold Heading Dies undergo stringent quality control measures during the manufacturing process. This includes rigorous testing for hardness, toughness, and dimensional accuracy. By adhering to the highest quality standards, YG8 guarantees that only top-notch products reach the hands of its customers, enabling them to achieve unparalleled results in their cold forging operations.As the demand for precision metal components continues to rise, the importance of selecting the right tools and materials cannot be overstated. The YG8 Tungsten Carbide Cold Heading Dies stand as a testament to the commitment of providing manufacturers with innovative and high-quality solutions. With their exceptional durability, accuracy, and customization options, the YG8 brand is poised to revolutionize the cold forging industry, enabling manufacturers to stay ahead of the competition and meet the evolving needs of their customers.

How Cemented Carbide Drawing Dies are Made and Used

Cemented Carbide Drawing Die Proves to Be a Game-Changer in ManufacturingThe manufacturing industry has seen significant growth over the years, with new technologies constantly emerging in the market. One of the recent groundbreaking inventions in the industry is the Cemented Carbide Drawing Die - a product that has revolutionized the manufacturing of wires, tubes, and steel bars. This remarkable invention has shown to be a game-changer in the industry, offering manufacturers the ability to produce high-quality products efficiently and effectively.Cemented Carbide Drawing Die is a product made from a combination of tungsten carbide and cobalt. Through advanced engineering, technicians can create a mold that helps draw and shape a wide range of metals into the desired shape and size. Drawing is the process of reducing the diameter of metal rod or coiled wire by pulling them through a series of dies. The final product produced is usually used for different industrial applications.Cemented Carbide Drawing Die is an excellent example of how advanced engineering and technology can provide manufacturers with outstanding results. This innovative product boasts of several benefits, including efficiency, durability, strength, and high resistance to wear and tear. In addition, cemented carbide drawing dies make it possible for manufacturers to produce metal products that are perfectly shaped, with high precision and accuracy. This feature is crucial in ensuring the production of high-quality metal products.One of the companies that have embraced the use of cemented carbide drawing dies is the company (name removed). The company has been in operation for several years and has established itself as a leader in the manufacturing industry. The company prides itself on offering high-quality wire and tube drawing dies, rolls, and other metal forming tools.The use of cemented carbide drawing dies has enabled (name removed) to produce products that meet their clients' specific needs and requirements. The company's die manufacturing division uses advanced techniques and state-of-the-art equipment to produce high-quality products. By utilizing cutting-edge technologies, the company ensures that their dies carry out their function effectively and efficiently.Cemented carbide drawing dies have allowed (name removed) to reduce production cycle times, improve process efficiency and produce high-quality metal products. The quality of the final product produced is a result of the precision and accuracy of the cemented carbide drawing dies. The dies ensure that the wire and tube products produced by the company match the exact specifications given by the client.The high resistance to wear and tear of cemented carbide drawing dies ensures durability and reduces production costs. This quality makes it possible for (name removed) to produce products that outlast their competitors' products in the market.The cemented carbide drawing die also shows a significant improvement in terms of the shape and size of the final product produced. The dies give a high level of precision and accuracy, resulting in high-quality products.(Name removed) believes that the adoption of cemented carbide drawing dies has given them a competitive edge in the market. The product has enabled them to meet the high demands of their customers, produce high-quality products efficiently, and maintain cost-efficiency.The market for wire and tube drawing dies products is highly competitive, with many companies jostling for market share. In such a market, companies must adopt innovative and advanced technologies to gain a competitive edge. The cemented carbide drawing die is a product that has given (name removed) this edge and will continue to be a game-changer in the industry.In conclusion, the cemented carbide drawing die is one of the most significant innovations in the manufacturing world. Its efficiency, durability, strength, and high resistance to wear and tear make it an essential tool for the production of high-quality metal products. Companies that have adopted this product, such as (name removed), have been able to take advantage of the benefits that this product offers. Cemented carbide drawing dies will continue to transform the manufacturing industry, offering companies an opportunity to meet the high demands of their clients effectively.

Enhance Your Turning Applications with High-Performance Carbide Inserts

Carbide Inserts for Turning Applications Offer Enhanced Durability and PrecisionCarbide inserts for turning applications have emerged as one of the popular cutting tools in the manufacturing industry. These inserts are designed with high-performance materials, which enhance their durability and precision capabilities. Carbide inserts are cutting-edge technology tools that can be used for turning, milling, drilling, and other cutting applications.A leading manufacturer and supplier of carbide inserts has recently introduced a range of carbide inserts for turning applications. The company's new products are designed to cater to the needs of all manufacturing industries, ensuring that clients receive superior quality and precision tools.The company has been providing the manufacturing industry with premium quality carbide inserts for more than a decade. Their team of experts has vast experience in the field of machining technology, and they employ innovative techniques to produce cutting-edge products that cater to the needs of the clients.Carbide inserts are widely used in turning applications because of their superior quality and precision capabilities. They are made from a combination of tungsten carbide and cobalt, which makes them harder than high-speed steel. Carbide inserts are also resistant to high temperatures, ensuring that they can withstand the heat generated during the cutting process.The company's new line of carbide inserts for turning applications is designed to offer improved performance, higher durability, and precision. The new range is available in different grades and designs, making it suitable for multiple turning applications, from roughing to finishing. The range includes inserts, inserts with chipbreakers, and inserts for heavy-duty roughing, among others.The company's carbide inserts for turning applications are highly versatile and can be used for a wide range of materials. They are ideal for cutting hard materials like steel, stainless steel, cast iron, and exotic alloys. The inserts' smooth finish and stable performance ensure that there is no chipping or breakage during the cutting process, which makes them ideal for industrial applications.Carbide inserts are designed to provide high accuracy and precision. The inserts' cutting edge produces a smooth finish, making it ideal for applications that require a high degree of precision. Additionally, carbide inserts are designed to produce chips that are easy to manage and dispose of, thus reducing the machine's downtime.The new range of carbide inserts for turning applications from the company is also cost-effective. Carbide inserts are designed to last longer than high-speed steel, which reduces the need for frequent changes and replacement. Additionally, the company's cost-effective pricing policy ensures that clients can obtain high-quality, reliable carbide inserts at an affordable price.The company's carbide inserts for turning applications are also environmentally friendly. Carbide inserts produce chips that can be recycled, which reduces manufacturing waste and environmental pollution. The company's products are designed with environmental responsibility in mind, and they are committed to reducing the carbon footprint associated with manufacturing.The company's carbide inserts for turning applications are easy to use and maintain. The inserts' high-performance materials make them resistant to wear and tear, which means less maintenance is required. Additionally, the company provides extensive technical support to ensure that clients can achieve the best results from their products.The company's commitment to client satisfaction is evident in the quality of their products and services. They have a team of experts who are always available to provide technical support and advice on the best carbide inserts for specific applications. The company also offers customized carbide inserts, ensuring that clients can obtain products that cater to their specific needs.In conclusion, carbide inserts for turning applications from the company are a game-changer in the manufacturing industry. They offer enhanced durability, precision, and versatility, making them ideal for a wide range of turning applications. The company's commitment to quality and affordability ensures that clients can obtain high-quality products at an affordable price, while their eco-friendly approach reduces manufacturing waste and environmental pollution.

High Quality Tungsten Carbide Wire Drawing Die for Industrial Use

Tungsten Carbide Wire Drawing Die is a crucial component in the wire drawing process, used to pull a metal wire through a specific shape and size. This die is essential in various industries such as automotive, aerospace, electronics, and construction, where high precision and quality wire products are required. With the increasing demand for high-performance wire drawing dies, {Company Name} continues to be a leading provider of tungsten carbide wire drawing dies, offering superior quality and reliable performance.{Company Name} has been a pioneering force in the development and manufacturing of tungsten carbide wire drawing dies for many years. The company has established a strong reputation for delivering high-quality products that meet and exceed the expectations of its customers. With a dedicated team of engineers, technicians, and experts, {Company Name} is committed to continuous innovation and improvement in the design and production of tungsten carbide wire drawing dies.The tungsten carbide wire drawing dies offered by {Company Name} are known for their exceptional strength, wear resistance, and durability. These qualities make them the ideal choice for demanding wire drawing applications, where the die needs to withstand high stress, pressure, and temperature. The superior hardness and toughness of tungsten carbide ensure that the wire drawing dies maintain their shape and dimensions, resulting in consistent and precise wire products.{Company Name} takes great pride in its state-of-the-art manufacturing facilities, equipped with advanced machinery and technology for producing tungsten carbide wire drawing dies of the highest quality. The company's production processes are carefully controlled and monitored to ensure that each die meets the strictest standards for performance and reliability. Additionally, {Company Name} conducts thorough quality testing and inspection to guarantee that every wire drawing die leaving its facility is flawless and ready for use.One of the key advantages of {Company Name}'s tungsten carbide wire drawing dies is their versatility and compatibility with a wide range of metals and alloys. Whether it's steel, aluminum, copper, or any other metal, these dies are designed to deliver exceptional results across different wire drawing applications. This flexibility makes them a preferred choice for manufacturers and producers in various industries who rely on high-quality wire products for their operations.{Company Name} understands the importance of providing superior customer support and service. The company's dedicated team of experts is always available to assist customers with their specific requirements and technical inquiries. Whether it's custom die designs, material recommendations, or troubleshooting assistance, {Company Name} is committed to ensuring that its customers receive the highest level of support and satisfaction.In conclusion, {Company Name} continues to be at the forefront of the industry as a leading provider of tungsten carbide wire drawing dies. With a focus on innovation, quality, and customer satisfaction, the company has established a strong presence and reputation in the market. By offering superior products and exceptional service, {Company Name} remains the preferred choice for businesses and industries seeking high-performance wire drawing dies for their operations.