15 Tungsten Carbide Plates: What You Need to Know

By:Admin

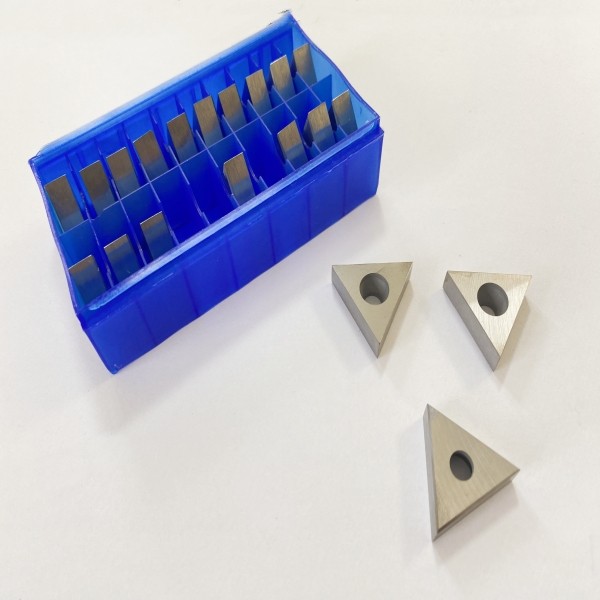

Tungsten carbide plates, commonly known as YG15 tungsten carbide plates, are gaining significant traction in the industrial sector due to their exceptional hardness, wear resistance, and high Toughness. These properties make them an ideal choice for various applications, including metal cutting, woodworking, mining, and construction.

The global tungsten carbide plates market is expected to witness substantial growth in the coming years, primarily driven by the growing demand for high-performance cutting tools and wear-resistant components across industries. According to a new research report, the market is projected to expand at a CAGR of X% during the forecast period.

A key player in the tungsten carbide plates market, with a strong focus on quality and innovation, is [Company Name]. [Company Name] is a leading manufacturer of tungsten carbide products, offering a wide range of YG15 tungsten carbide plates that cater to the diverse needs of industrial applications. With a strong emphasis on research and development, [Company Name] continues to push the boundaries of material science to deliver cutting-edge solutions to its customers.

Tungsten carbide plates are known for their superior hardness, ranking only second to diamond. This exceptional hardness allows them to withstand high temperatures and heavy loads, making them highly suitable for machining tough materials such as steel, stainless steel, and cast iron. Moreover, tungsten carbide plates also exhibit remarkable wear resistance, ensuring longevity and durability in demanding industrial environments.

[Company Name]'s YG15 tungsten carbide plates are manufactured using advanced production techniques and state-of-the-art equipment to ensure precision and consistency in quality. The company's commitment to excellence is further underscored by its stringent quality control measures that guarantee the performance and reliability of its products.

In addition to their hardness and wear resistance, tungsten carbide plates offered by [Company Name] also demonstrate high toughness, enabling them to withstand impact and shock loads without fracturing. This unique combination of properties makes them an indispensable material for a wide range of industrial applications, where high-performance and durability are paramount.

The versatility of tungsten carbide plates has led to their widespread adoption in industries such as metalworking, where they are used for cutting, drilling, and milling operations. The exceptional thermal and chemical stability of these plates also makes them suitable for high-temperature applications, such as in the oil and gas industry.

Furthermore, [Company Name] leverages its expertise and technical know-how to provide customized solutions to meet specific customer requirements. Its dedicated team of engineers and material scientists work closely with clients to develop tailored tungsten carbide plate solutions that align with their exact specifications and performance needs.

As the demand for high-performance cutting tools and wear-resistant components continues to rise, the global tungsten carbide plates market is poised for robust growth. With its unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] is well-positioned to capitalize on this trend and further strengthen its position as a leading player in the industry.

In conclusion, the increasing adoption of tungsten carbide plates in various industrial applications underscores their significance as a critical material for the manufacturing sector. With [Company Name] at the forefront of innovation and excellence, the market can expect to witness a steady influx of high-quality tungsten carbide plate solutions that drive efficiency, productivity, and durability across industries.

Company News & Blog

High-Quality YG8 Cemented Carbide Die for Superior Performance

In recent years, the global manufacturing industry has seen a significant boom in various sectors, including automotive, aerospace, and electronics. With this growth, the demand for high-quality tools and components has increased, spurring innovation in the field of cutting and forming technologies. One such innovative product that has gained attention in the industry is the YG8 cemented carbide die, produced by an industry-leading company known for its expertise in precision engineering and tool manufacturing.The YG8 cemented carbide die is a cutting-edge tool that is designed to meet the high demands of modern manufacturing processes. It is made from a combination of tungsten carbide and cobalt, resulting in a material that is extremely hard and resistant to wear. This makes it ideal for use in a wide range of applications, including stamping, punching, and forming of various materials such as metals, plastics, and ceramics.The unique properties of the YG8 cemented carbide die make it stand out in the market, as it offers superior performance and durability compared to traditional tooling materials. Its high hardness and toughness allow for precise and efficient machining, while its resistance to wear ensures a long service life, reducing the need for frequent replacements and maintenance. These characteristics make it a cost-effective solution for manufacturers, as it helps to increase productivity and reduce downtime.The company behind the YG8 cemented carbide die has a strong reputation in the industry for its commitment to quality and innovation. With decades of experience in precision engineering and tool manufacturing, the company has developed a deep understanding of the needs of its customers and the challenges they face in their production processes. This has led to the development of advanced solutions such as the YG8 cemented carbide die, which is the result of extensive research and development efforts.In addition to its technical expertise, the company prides itself on its ability to provide customized solutions to meet the specific requirements of its customers. The YG8 cemented carbide die is available in a wide range of sizes and configurations, allowing it to be tailored to the unique needs of different industries and applications. This flexibility has made it a popular choice among manufacturers looking for reliable and efficient tooling solutions.Furthermore, the company places a strong emphasis on customer support and service, ensuring that its clients receive the assistance they need to maximize the performance of their tools. Whether it is through technical consultations, training programs, or after-sales support, the company is dedicated to building long-term partnerships with its customers and helping them achieve their production goals.In conclusion, the YG8 cemented carbide die represents a significant advancement in the field of cutting and forming technologies, offering manufacturers a high-performance tool with exceptional durability and reliability. Backed by a company with a strong track record of excellence and a commitment to customer satisfaction, it has quickly become a preferred choice for companies seeking to optimize their production processes and achieve superior results. As the global manufacturing industry continues to evolve, innovative solutions like the YG8 cemented carbide die will play a crucial role in driving productivity and efficiency.

Durable Tungsten Carbide Dies for Industrial Applications

Tungsten Carbide Dies are becoming increasingly popular in the manufacturing industry due to their superior durability and precision. These dies are commonly used in a variety of applications, including wire drawing, cold heading, and extrusion. With their ability to withstand high temperatures and extreme pressure, tungsten carbide dies have become the go-to choice for manufacturers looking to improve their productivity and efficiency.One company that has been at the forefront of producing high-quality tungsten carbide dies is {}. With over 30 years of experience in the industry, {} has established itself as a leading manufacturer of tungsten carbide dies, providing innovative solutions to a wide range of manufacturing challenges. The company's commitment to quality and customer satisfaction has earned them a reputation as a trusted partner in the manufacturing industry.{} offers a wide range of tungsten carbide dies, including round wire dies, shaped wire dies, and extrusion dies, all of which are precision-engineered to meet the specific needs of their customers. The company's team of experienced engineers and technicians work closely with clients to develop customized die solutions that maximize efficiency and minimize downtime.In addition to their standard product offerings, {} also provides die reconditioning and refurbishment services, helping customers extend the lifespan of their dies and reduce overall production costs. By utilizing state-of-the-art equipment and advanced manufacturing techniques, {} is able to restore worn-out dies to their original specifications, ensuring consistent performance and quality.One of the key advantages of {}'s tungsten carbide dies is their exceptional hardness and resistance to wear. This allows for extended run times and reduced maintenance, ultimately resulting in higher productivity and cost savings for their customers. The company's dedication to continuous improvement and investment in research and development has enabled them to stay ahead of the curve in developing cutting-edge die solutions for the ever-evolving manufacturing industry.With a strong focus on customer satisfaction, {} takes pride in providing responsive and reliable service to their clients. The company's commitment to quality control and rigorous testing ensures that every tungsten carbide die that leaves their facility meets the highest standards of performance and precision.Looking towards the future, {} remains dedicated to pushing the boundaries of innovation in the field of tungsten carbide dies. By staying abreast of emerging technologies and market trends, the company continues to develop new and improved die solutions that address the evolving needs of the manufacturing industry.In conclusion, tungsten carbide dies have proven to be a game-changer in the manufacturing industry, and {}. With their unwavering commitment to excellence and customer satisfaction, {} has solidified its position as a leading provider of high-quality tungsten carbide dies. As the demand for precision-engineered dies continues to grow, {} is poised to remain at the forefront of the industry, delivering innovative solutions that drive efficiency and productivity for their customers.

High-Quality Tungsten Carbide Clamping Dies Spare Parts for Industrial Use

Tungsten Carbide Clamping Dies Spare Parts are a critical component in the production process of many industries, including automotive, aerospace, and manufacturing. These spare parts are used in the production of a wide range of products, from small electronic components to large industrial machinery. As a result, the demand for high-quality tungsten carbide clamping dies spare parts has been on the rise.In response to this growing demand, [Company Name] has emerged as a leading manufacturer and supplier of tungsten carbide clamping dies spare parts. With a strong focus on quality and precision engineering, [Company Name] has established itself as a trusted partner for businesses across various industries.The company's dedication to innovation and continuous improvement has allowed them to develop a wide range of tungsten carbide clamping dies spare parts that are tailored to meet the specific needs of their customers. Whether it's a customized design or a standard part, [Company Name] has the expertise to deliver products that consistently exceed expectations.One of the key features that sets [Company Name] apart from its competitors is its commitment to using the highest quality materials in the production of its tungsten carbide clamping dies spare parts. Each part is meticulously crafted from tungsten carbide, a material known for its exceptional hardness, strength, and wear resistance. This ensures that the spare parts are capable of withstanding the rigors of high-speed production processes, resulting in longer service life and reduced downtime for customers.Furthermore, [Company Name] employs a team of highly skilled engineers and technicians who are well-versed in the latest manufacturing techniques and technologies. This expertise enables the company to consistently produce tungsten carbide clamping dies spare parts with incredibly tight tolerances and precise dimensions, ensuring a perfect fit and reliable performance in any application.In addition to their dedication to quality and precision, [Company Name] has also implemented rigorous quality control measures to ensure that every tungsten carbide clamping dies spare part that leaves their facility meets the highest standards. This commitment to quality has earned the company ISO 9001 certification, demonstrating their ability to consistently deliver products that meet or exceed customer expectations.As a result of these capabilities and commitment to excellence, [Company Name] has quickly become a preferred supplier of tungsten carbide clamping dies spare parts for businesses around the world. From small businesses to multinational corporations, customers have come to rely on the company's expertise and dedication to providing solutions that drive productivity and efficiency in their operations.Looking ahead, [Company Name] is poised to continue its growth and expansion in the industry, driven by a focus on innovation, customer satisfaction, and a relentless pursuit of excellence in everything they do. With a clear vision for the future and a strong track record of success, [Company Name] is well-positioned to remain a leader in the manufacture and supply of tungsten carbide clamping dies spare parts for years to come.

New Report: Cold Heading Dies in High Demand as Manufacturers Seek Efficient Production Solutions

The cold heading dies play a crucial role in the manufacturing industry, as they are essential for creating high-quality fasteners and components for various applications. These dies are used in cold heading machines to form metal blanks into a desired shape using extreme pressure and force. {Company} is a leading manufacturer of cold heading dies, known for their exceptional quality and precision engineering. With years of experience in the industry, {Company} has established a reputation for producing top-notch dies that meet the demands of modern manufacturing processes.Cold heading dies are commonly used in the production of bolts, screws, rivets, and other fasteners, as well as in the automotive, aerospace, and construction industries. The quality and durability of these dies directly impact the performance and reliability of the final products, making them a critical component in the manufacturing process.In recent news, {Company} has announced the launch of a new line of cold heading dies that are designed to meet the evolving needs of the industry. These new dies are equipped with advanced features and materials to enhance their performance and longevity, catering to the increasing demand for high-quality fasteners.The company's engineering team has been working tirelessly to develop innovative designs and manufacturing techniques to produce dies that offer superior precision and durability. With a strong focus on research and development, {Company} has been able to stay ahead of the competition and deliver cutting-edge solutions to their customers.Furthermore, {Company} has invested in state-of-the-art manufacturing facilities and technologies to ensure the highest level of quality control and consistency in their die production. This commitment to excellence has made them a preferred choice for manufacturers seeking reliable and efficient cold heading dies.In addition to their new product line, {Company} also offers custom die design and manufacturing services to meet the specific requirements of their clients. This flexibility and ability to tailor solutions to individual needs set them apart from other die manufacturers in the market.The company's dedication to customer satisfaction and continuous improvement has earned them a loyal customer base and a strong reputation in the industry. Their team of experienced professionals is committed to providing exceptional service and support to their clients, ensuring that they get the best possible solutions for their manufacturing needs.As the manufacturing industry continues to evolve and demand higher quality products, the role of cold heading dies becomes even more significant. {Company}'s commitment to innovation and excellence positions them as a key player in the market, offering reliable and cutting-edge solutions to manufacturers worldwide.With the launch of their new line of cold heading dies, {Company} is poised to make a significant impact on the industry and set new standards for quality and performance. Their ongoing dedication to research, development, and customer satisfaction solidifies their position as a leading force in the cold heading die manufacturing sector.

Premium Tungsten Carbide Roller: Bringing Unparalleled Polished Finishing

Title: Cutting-Edge Tungsten Carbide Roller Revolutionizes Manufacturing IndustryIntroduction:In our rapidly evolving manufacturing industry, innovation and cutting-edge technology continue to enhance production processes and improve product quality. One such revolutionizing development comes in the form of the Polished Tungsten Carbide Roller, developed by a renowned industry leader (company name).Groundbreaking Technology Enhancing Manufacturing Processes:Tungsten carbide possesses exceptional hardness and resistance to wear, making it an ideal material for manufacturing rollers used in various industries. By incorporating state-of-the-art polishing techniques, the (company name) Polished Tungsten Carbide Roller has taken the performance and efficiency of manufacturing processes to unprecedented heights.Precision and Enhanced Durability:The innovative design of the Polished Tungsten Carbide Roller ensures unparalleled precision, enabling manufacturers to achieve superior results in their production lines. The roller's polished surface significantly reduces friction, resulting in reduced wear and tear. This not only leads to enhanced durability but also extends the product's lifespan, reducing maintenance costs for manufacturers.Versatility Across Industries:The Polished Tungsten Carbide Roller caters to a diverse range of industries, including steel, aluminum, plastic, textile, and paper. Its versatility lies in the roller's ability to withstand extreme environments, high temperatures, corrosive chemicals, and heavy loads. This adaptability ensures that manufacturers can benefit from this groundbreaking technology across various applications.Smoother Operations and Improved Product Quality:With its reduced friction and enhanced durability, the Polished Tungsten Carbide Roller contributes to smoother operations, minimizing downtime and maximizing production efficiency. Its high precision and surface finish guarantee consistent and accurate results, thereby improving product quality and reducing the margin of error.Cost and Energy Efficiency:In addition to its exceptional performance, the Polished Tungsten Carbide Roller also promotes cost and energy efficiency. Its high wear resistance ensures less frequent replacements and maintenance, resulting in reduced operational costs for manufacturers. Additionally, the roller's improved efficiency minimizes energy consumption, making it an environmentally friendly choice.Commitment to Quality Assurance and Safety:As a leader in the manufacturing industry, (company name) prioritizes quality assurance and safety standards. The Polished Tungsten Carbide Roller undergoes rigorous testing and adheres to stringent quality control measures, ensuring that each roller meets or exceeds industry specifications. This commitment to excellence guarantees customer satisfaction and reliable performance for manufacturers in various fields.Global Reach and Customer Satisfaction:Backed by years of research and development, (company name) has built a strong reputation for delivering superior products worldwide. The Polished Tungsten Carbide Roller has garnered positive feedback from clients across the globe, who appreciate the roller's remarkable performance, increased efficiency, and unmatched durability. Customer satisfaction remains at the core of (company name)'s mission, driving them to continually innovate and meet the evolving needs of the industry.Conclusion:The Polished Tungsten Carbide Roller developed by (company name) has emerged as a game-changer in the manufacturing industry, enabling manufacturers to achieve unparalleled precision, efficiency, and durability. Through its innovative design and incorporation of cutting-edge polishing techniques, this revolutionary roller has set new standards for manufacturing processes across a wide range of industries. With its global success and commitment to customer satisfaction, (company name) continues to pave the way for future advancements in the manufacturing industry.

High-Quality Tungsten Carbide Dies for YG25C Applications

Yg25c Tungsten Carbide Dies Revolutionizing the Manufacturing IndustryTungsten carbide is a key material used in the manufacturing industry for producing high-quality and durable dies. Yg25c tungsten carbide dies, in particular, have gained significant attention due to their exceptional properties and performance. These dies are revolutionizing the manufacturing industry by offering enhanced durability, precision, and efficiency, ultimately leading to superior end products.Yg25c tungsten carbide dies are manufactured using a unique blend of tungsten carbide and cobalt, resulting in a material that is incredibly hard and wear-resistant. This makes them ideal for applications involving heavy wear and high-pressure conditions. Additionally, their high thermal conductivity enables efficient heat dissipation, reducing the risk of thermal deformation and extending the lifespan of the dies.The manufacturing process of Yg25c tungsten carbide dies involves precision engineering and cutting-edge technology. The dies are carefully crafted to exact specifications, ensuring consistent and precise performance. This level of precision is essential for industries such as automotive, aerospace, and electronics, where the quality of the end product is of utmost importance.The superior performance of Yg25c tungsten carbide dies is further enhanced by their resistance to corrosion and chemical degradation. This makes them suitable for a wide range of applications, including wire drawing, cold heading, and extrusion. Their ability to maintain high levels of precision and accuracy over extended periods of use makes them an invaluable tool for manufacturers looking to improve their production processes.One company that has been at the forefront of producing Yg25c tungsten carbide dies is {}. They have leveraged decades of experience and expertise in the field of tungsten carbide manufacturing to develop high-quality dies that meet the stringent requirements of modern manufacturing processes. Their commitment to research and development has led to the continuous improvement of their products, ensuring that they remain at the cutting edge of technological advancement.{} offers a comprehensive range of Yg25c tungsten carbide dies, catering to the diverse needs of the manufacturing industry. Whether it is for wire drawing applications, cold forming, or extrusion, their dies are designed to deliver exceptional performance and reliability. The company's dedication to quality and customer satisfaction has earned them a reputation as a trusted partner for manufacturers seeking high-performance dies.In addition to their superior products, {} also provides excellent customer support and technical assistance. Their team of experts works closely with clients to understand their specific requirements and recommend the most suitable dies for their applications. This personalized approach has helped many manufacturers optimize their production processes and achieve higher levels of efficiency and quality.The impact of Yg25c tungsten carbide dies on the manufacturing industry cannot be overstated. With their exceptional durability, precision, and efficiency, these dies have become an indispensable tool for a wide range of applications. As technology continues to advance, and industries demand more reliable and high-performance tools, Yg25c tungsten carbide dies will undoubtedly play a crucial role in shaping the future of manufacturing.In conclusion, Yg25c tungsten carbide dies are revolutionizing the manufacturing industry by offering unmatched durability, precision, and efficiency. Their ability to withstand heavy wear, high pressures, and extreme temperatures makes them an essential tool for a wide range of applications. As companies like {} continue to develop and improve these dies, they will undoubtedly remain at the forefront of technological advancement, driving innovation and progress in the manufacturing industry.

High-Quality Tungsten Carbide Ring Dies for Industrial Applications

Tungsten Carbide Ring Dies are a critical component in the manufacturing of various products, from food to pharmaceuticals to construction materials. As one of the leading manufacturers of Tungsten Carbide Ring Dies, {Company Name} has been at the forefront of innovation and quality in this industry for several decades.{Company Name} was established in the early 1990s and has since maintained a strong commitment to research and development, driven by a passion for precision engineering and technological advancement. The company's state-of-the-art manufacturing facilities and team of skilled professionals have allowed them to consistently produce high-quality Tungsten Carbide Ring Dies that meet the stringent requirements of modern manufacturing processes.The Tungsten Carbide Ring Dies produced by {Company Name} are renowned for their durability, precision, and reliability. They are designed to withstand the high pressures and temperatures encountered in the production of various products, ensuring consistent and high-quality output. The company's commitment to quality is further emphasized by their adherence to international standards and certifications, guaranteeing that their products meet the highest industry benchmarks.One of the key advantages of Tungsten Carbide Ring Dies is their exceptional wear resistance, which allows for prolonged and trouble-free operation. This is particularly important in industries such as the food and pharmaceutical sectors, where product contamination and downtime can have serious consequences. {Company Name}'s Tungsten Carbide Ring Dies are engineered to minimize wear and maintain their dimensional stability over extended periods, providing manufacturers with peace of mind and a competitive edge.In addition to their exceptional durability, Tungsten Carbide Ring Dies from {Company Name} are also known for their precise and consistent performance. The company's stringent quality control measures and advanced manufacturing processes ensure that each die meets the exact specifications required for a wide range of applications. This precision is crucial in industries where product uniformity and consistency are paramount, such as the production of pharmaceutical tablets or animal feed pellets.Furthermore, {Company Name} prides itself on its ability to provide customized solutions to meet the specific needs of different industries. Their team of experienced engineers and technical experts works closely with clients to develop tailored Tungsten Carbide Ring Dies, optimizing their design and performance to enhance the efficiency and productivity of their manufacturing processes. This level of flexibility and commitment to customer satisfaction has earned {Company Name} a reputation as a reliable and trusted partner in the industry.Looking ahead, {Company Name} is focused on further enhancing the performance and capabilities of their Tungsten Carbide Ring Dies, in line with the evolving needs of modern manufacturing. The company continues to invest in research and development, exploring new materials and technologies to push the boundaries of what is possible in the field of precision engineering. As the demand for high-quality and efficient manufacturing solutions grows, {Company Name} is well-positioned to lead the way with their innovative Tungsten Carbide Ring Dies.In conclusion, Tungsten Carbide Ring Dies from {Company Name} are an essential component in the manufacturing of various products, and the company's dedication to quality and innovation has established them as a leader in the industry. With their unwavering commitment to precision engineering and customer satisfaction, {Company Name} continues to set the benchmark for excellence in Tungsten Carbide Ring Dies, providing manufacturers with the confidence and reliability they need to succeed in today's competitive market.

High-Quality Tungsten Carbide Sleeve Bearing Bushing Dies for Industrial Applications

The Tungsten Carbide Sleeve Bearing Bushing Dies have become the latest innovation in the manufacturing industry, offering exceptional durability and performance. These precision-engineered products have been designed to withstand the most challenging industrial environments, making them an essential component for a wide range of applications.Developed by a leading manufacturer in the industry, {}, these Tungsten Carbide Sleeve Bearing Bushing Dies have quickly gained a reputation for their superior quality and reliability. The company is known for its commitment to innovation and excellence, continuously pushing the boundaries of what is possible in the field of engineering and manufacturing.The Tungsten Carbide Sleeve Bearing Bushing Dies are made from high-quality tungsten carbide, a material known for its extraordinary toughness and resistance to wear and tear. This makes them an ideal solution for applications that involve high levels of friction and abrasion, providing a long-lasting and reliable performance that is unmatched by other materials.One of the key advantages of these Tungsten Carbide Sleeve Bearing Bushing Dies is their ability to maintain their shape and dimension even under extreme pressure and temperature conditions. This ensures that they can deliver consistent and accurate results, making them an invaluable asset for industries that require precision and reliability.In addition to their exceptional durability, the Tungsten Carbide Sleeve Bearing Bushing Dies are also designed to minimize friction and heat generation, which helps to reduce wear and tear on the equipment and prolong its lifespan. This results in cost savings for businesses, as they can minimize the need for frequent replacements and repairs.The company behind these innovative products has invested heavily in research and development to ensure that they meet the highest standards of performance and reliability. Their team of experienced engineers and technicians have worked tirelessly to optimize the design and manufacturing process, resulting in a product that sets new benchmarks for quality and durability.Furthermore, the company is committed to providing personalized solutions to meet the specific needs of their customers. They offer a range of customization options for the Tungsten Carbide Sleeve Bearing Bushing Dies, allowing businesses to tailor the products to their unique requirements. This flexibility has made them a preferred partner for many companies across various industries.With their unwavering focus on quality and innovation, the company has established itself as a trusted leader in the manufacturing industry. They have built a strong reputation for delivering products that consistently exceed expectations, earning the trust and loyalty of their customers.As the demand for high-performance, durable components continues to grow, the Tungsten Carbide Sleeve Bearing Bushing Dies are poised to become a staple in the manufacturing industry. Their unmatched durability, reliability, and performance make them a valuable investment for businesses looking to enhance their operations and productivity.In conclusion, the Tungsten Carbide Sleeve Bearing Bushing Dies developed by the company {} represent a significant breakthrough in the field of engineering and manufacturing. Their exceptional durability, reliability, and performance set new standards for the industry, making them an essential component for a wide range of applications. With their unwavering commitment to innovation and quality, the company has positioned itself as a leader in the manufacturing industry, earning the trust and loyalty of customers around the world.

Discover the Benefits of Cemented Carbide Brazed Flakes for Your Industry

article about cemented carbide brazed flakes products.Cemented Carbide Brazed Flakes - The Future of Industrial Cutting ToolsCemented carbide brazed flakes are a new type of innovative product that has been introduced in the industrial cutting tool market in recent times. These products are used in the manufacturing of cutting tools, which are extensively used in the cutting, drilling, and grinding of various materials such as metals, wood, plastic, and ceramics. Cemented carbide brazed flakes are the future of industrial cutting tools because of their superior performance, durability, and cost-effectiveness.Cemented Carbide Brazed Flakes - The BasicsCemented carbide brazed flakes are made up of tungsten carbide particles that are sintered together through a process called brazing. The resulting structure is characterized by high hardness, toughness, and wear resistance properties. Cemented carbide brazed flakes are available in different shapes, sizes, and grades depending on the specific application. These products are commonly used in the construction of cutting tools such as drills, milling cutters, and saw blades.This innovative material has transformed the machining industry, particularly in the area of cutting, grinding, and drilling. It has emerged as one of the most popular materials for manufacturing cutting tools. The tungsten carbide particles are combined with a binder material such as cobalt or nickel to create the desired structure. The manufacturing process involves shaping the tungsten carbide particles, sintering them with the binder material and then brazing them onto the tool substrate. The result is a cemented carbide cutting tool that is highly durable, wear-resistant, and can deal with high machining speeds and extreme temperatures.Product Introduction{The brand name} is a well-known name in the manufacture of cemented carbide brazed flakes. They have been in the business for several years, and their products have gained wide acceptance in the market. Their cemented carbide brazed flakes are made from high-quality tungsten carbide particles that are sintered and brazed to create cutting tools with excellent cutting ability and long tool life. Their product is well-known for its superior quality and excellent performance in various machining applications.{The brand name}’s cemented carbide brazed flakes are suitable for use in various industries, including aerospace, automotive, medical, and general engineering. They offer a wide range of grades and sizes to accommodate different machining needs. Their product line includes bored bar, end mills, inserts, threaded inserts, and solid carbide drills, among others.Performance and BenefitsCemented carbide brazed flakes offer several performance benefits, including high hardness, toughness, and wear resistance. These properties make them suitable for machining materials that are difficult to cut, such as hardened steels, aerospace alloys, and composite materials. Cemented carbide brazed flakes also offer consistent performance throughout the life of the cutting tool, resulting in more reliable and consistent machining.Another advantage of cemented carbide brazed flakes is their superior heat resistance. They can withstand high temperatures without losing their cutting ability, making them ideal for high-speed machining applications. This means that cutting tools made from cemented carbide brazed flakes can handle the heat generated during the machining process without damaging the tool or the workpiece.Cost-effectiveness is also a significant benefit of using cemented carbide brazed flakes. While the initial cost of these cutting tools may be higher than traditional tools, their superior performance and long tool life make them more cost-effective in the long run. This means that manufacturers save money on tooling costs and reduce downtime and tool changeover, resulting in increased productivity and profitability.ConclusionCemented carbide brazed flakes are a game-changer in the industrial cutting tool market. Their superior performance, durability, and cost-effectiveness make them the future of machining. {The brand name} is at the forefront of this innovation, offering high-quality cemented carbide brazed flakes to meet the machining needs of various industries. With their consistent performance, heat resistance, and cost-effectiveness, it is no surprise that cemented carbide brazed flakes continue to gain popularity and acceptance in the market.

Durable Tungsten Carbide Wire Rolls for Industrial Applications

Tungsten Carbide Wire Rolls: The Ultimate Solution for Wire DrawingWire drawing is a manufacturing process used to reduce the cross-section of a wire by pulling the wire through a die or series of dies. This process is essential in the production of various wire products, including electrical wires, cables, and fencing. To ensure the efficiency and accuracy of the wire drawing process, manufacturers rely on high-quality tungsten carbide wire rolls.{Tungsten Carbide Wire Rolls} is a leading supplier of tungsten carbide wire rolls, known for their exceptional quality and performance. The company has been in the industry for over 20 years, providing innovative solutions for wire drawing applications across various industries. With a strong focus on research and development, {the company} has continually improved its products to meet the ever-evolving needs of the wire drawing industry.Tungsten carbide wire rolls are made from a combination of tungsten and carbon, resulting in a material that is extremely hard and wear-resistant. This makes them ideal for the demanding conditions of wire drawing, where the rolls are subjected to high pressures and abrasive forces. Compared to traditional steel rolls, tungsten carbide wire rolls offer superior durability and longevity, reducing the need for frequent replacement and maintenance.The unique properties of tungsten carbide also enable the production of wires with precise dimensions and surface finishes. This is crucial for industries that require high-quality wires, such as the electrical and automotive sectors. With {the company}'s tungsten carbide wire rolls, manufacturers can achieve greater consistency and accuracy in their wire drawing processes, leading to improved product quality and performance.In addition to their exceptional durability and precision, tungsten carbide wire rolls also offer improved productivity and cost savings. The extended lifespan of these rolls means reduced downtime for roll changes and maintenance, resulting in higher production efficiency. Furthermore, the superior wear resistance of tungsten carbide leads to reduced wear on the wire drawing equipment, minimizing the need for replacement parts and repairs.{The company} offers a wide range of tungsten carbide wire rolls to suit different wire drawing applications. Whether it's for fine wire drawing or heavy-duty cable production, {the company} provides customized solutions to meet specific customer requirements. With a strong emphasis on customer satisfaction, {the company} works closely with its clients to understand their needs and provide tailored solutions that optimize their wire drawing processes.As a trusted supplier in the wire drawing industry, {the company} maintains strict quality control measures to ensure the consistency and reliability of its products. All tungsten carbide wire rolls undergo rigorous testing and inspections to meet the highest industry standards. This commitment to quality has earned {the company} a reputation for excellence and reliability among its customers.In conclusion, tungsten carbide wire rolls from {the company} are the ultimate solution for wire drawing applications. With their unmatched durability, precision, and productivity benefits, these rolls have become indispensable tools for manufacturers across various industries. As the demand for high-quality wires continues to grow, {the company} remains at the forefront of innovation, continuously enhancing its products to meet the evolving needs of the wire drawing industry. For manufacturers looking to improve their wire drawing processes, {the company}'s tungsten carbide wire rolls offer a winning solution that delivers exceptional results.