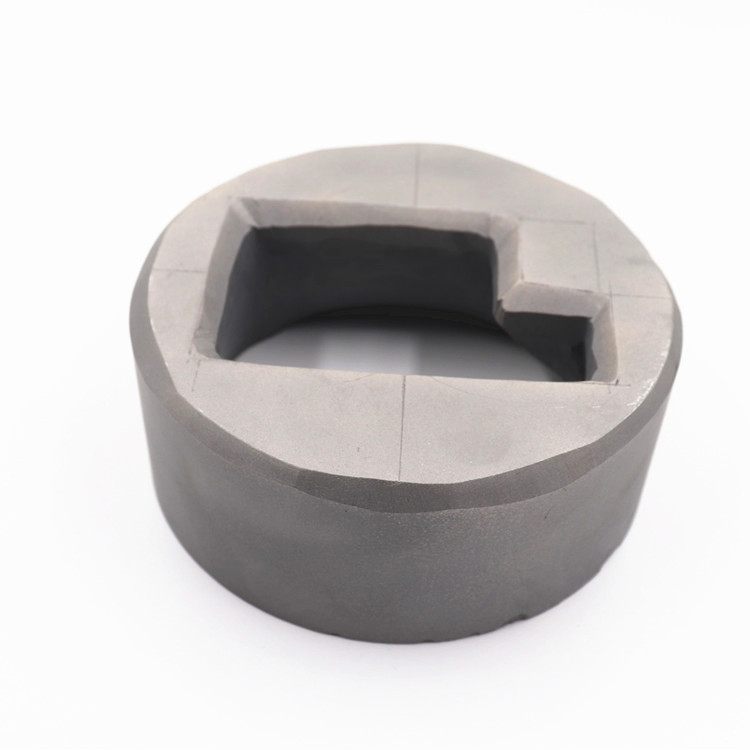

High-Quality YG8 Cemented Carbide Die for Superior Performance

By:Admin

The YG8 cemented carbide die is a cutting-edge tool that is designed to meet the high demands of modern manufacturing processes. It is made from a combination of tungsten carbide and cobalt, resulting in a material that is extremely hard and resistant to wear. This makes it ideal for use in a wide range of applications, including stamping, punching, and forming of various materials such as metals, plastics, and ceramics.

The unique properties of the YG8 cemented carbide die make it stand out in the market, as it offers superior performance and durability compared to traditional tooling materials. Its high hardness and toughness allow for precise and efficient machining, while its resistance to wear ensures a long service life, reducing the need for frequent replacements and maintenance. These characteristics make it a cost-effective solution for manufacturers, as it helps to increase productivity and reduce downtime.

The company behind the YG8 cemented carbide die has a strong reputation in the industry for its commitment to quality and innovation. With decades of experience in precision engineering and tool manufacturing, the company has developed a deep understanding of the needs of its customers and the challenges they face in their production processes. This has led to the development of advanced solutions such as the YG8 cemented carbide die, which is the result of extensive research and development efforts.

In addition to its technical expertise, the company prides itself on its ability to provide customized solutions to meet the specific requirements of its customers. The YG8 cemented carbide die is available in a wide range of sizes and configurations, allowing it to be tailored to the unique needs of different industries and applications. This flexibility has made it a popular choice among manufacturers looking for reliable and efficient tooling solutions.

Furthermore, the company places a strong emphasis on customer support and service, ensuring that its clients receive the assistance they need to maximize the performance of their tools. Whether it is through technical consultations, training programs, or after-sales support, the company is dedicated to building long-term partnerships with its customers and helping them achieve their production goals.

In conclusion, the YG8 cemented carbide die represents a significant advancement in the field of cutting and forming technologies, offering manufacturers a high-performance tool with exceptional durability and reliability. Backed by a company with a strong track record of excellence and a commitment to customer satisfaction, it has quickly become a preferred choice for companies seeking to optimize their production processes and achieve superior results. As the global manufacturing industry continues to evolve, innovative solutions like the YG8 cemented carbide die will play a crucial role in driving productivity and efficiency.

Company News & Blog

Top Benefits of Using Cemented Carbide Bars and Sheets in Manufacturing Processes

Cemented Carbide is a versatile and highly durable material that finds extensive applications in various industrial sectors. Its exceptional hardness and wear resistance make it an ideal choice for cutting tools, molds, and wear parts. One such prominent player in the cemented carbide industry is a company focused on producing top-quality Cemented Carbide Bar Sheets (brand name omitted).Cemented Carbide Bar Sheets, also known as tungsten carbide bar sheets, are manufactured using a process called powder metallurgy. The company employs advanced technology and state-of-the-art machinery to produce these versatile sheets. Tungsten carbide powder, along with a small percentage of binder metal, is compacted using high pressure and temperature, resulting in a dense and hard material.The exceptional characteristics of Cemented Carbide Bar Sheets are attributed to the properties of tungsten carbide, which has a melting point of 2,870 degrees Celsius and a hardness comparable to that of diamond. The addition of a binder metal, such as cobalt or nickel, enhances the toughness and strength of the material, making it well-suited for a wide range of applications.These Cemented Carbide Bar Sheets come in various shapes and sizes, catering to the specific needs of different industries. The company offers a comprehensive range of bar sheets, including flat bar sheets, square bar sheets, and round bar sheets, among others. Moreover, they can customize the dimensions and specifications of the bar sheets as per customer requirements.One of the prominent applications of Cemented Carbide Bar Sheets is in the manufacturing of cutting tools. The high hardness and wear resistance of these sheets make them ideal for producing drills, end mills, and turning tools. The company ensures precise manufacturing processes and stringent quality control measures to guarantee the superior performance and durability of their bar sheets.In addition to cutting tools, Cemented Carbide Bar Sheets are widely used in the molding industry. These sheets enable the production of precise and intricate molds for various applications, including injection molding and die-casting. The excellent dimensional stability and high thermal conductivity of cemented carbide make it an optimal choice for mold-making applications.Furthermore, Cemented Carbide Bar Sheets are also utilized in wear parts, such as wear plates and wear rings. These sheets offer outstanding resistance to abrasion, erosion, and impact, thereby increasing the lifespan and performance of machinery and equipment. Industries such as mining, oil and gas, and construction rely on these wear parts for their demanding operations.The company producing these Cemented Carbide Bar Sheets is renowned for its dedication to quality and customer satisfaction. They operate a state-of-the-art production facility equipped with the latest technology and machinery. Stringent quality control measures are implemented throughout the manufacturing process to ensure that each bar sheet meets the highest standards.Apart from quality, the company is committed to environmental sustainability. They adhere to strict guidelines and regulations to minimize their environmental footprint. By implementing energy-efficient practices and recycling methods, the company aims to contribute to a greener future.With a strong focus on research and development, the company continuously strives to innovate and improve its products. They collaborate with industry experts and invest in cutting-edge technologies to stay at the forefront of the cemented carbide industry. Through their relentless pursuit of excellence, the company aims to exceed customer expectations and establish long-lasting partnerships worldwide.In conclusion, Cemented Carbide Bar Sheets produced by this renowned company offer exceptional hardness, wear resistance, and versatility. With applications in cutting tools, molding, and wear parts, these bar sheets cater to the needs of various industries. The company's commitment to quality, sustainability, and innovation sets them apart in the cemented carbide industry. Their relentless pursuit of excellence ensures that customers receive top-quality products that meet the highest standards.

Chinese Company Develops New Carbide Technology

Carbide China, a leading provider of high-quality carbide products, has recently announced a significant expansion of its manufacturing facilities to meet the growing demand for its products in the global market. The company, which has been in operation for over 20 years, is known for its advanced technology, exceptional product quality, and reliable customer service.Carbide China offers a wide range of carbide products, including carbide inserts, end mills, drills, and other cutting tools. These products are widely used in the aerospace, automotive, medical, and oil and gas industries, among others. The company's products are known for their durability, precision, and high performance, making them a popular choice among manufacturers and industry professionals around the world.The expansion of Carbide China's manufacturing facilities comes as a response to the increasing demand for its products, both domestically and internationally. The company has experienced steady growth in recent years, thanks to its commitment to excellence and innovation in the carbide industry. By expanding its production capacity, Carbide China aims to better serve its existing customers while also reaching new markets and customers worldwide.In addition to expanding its manufacturing facilities, Carbide China is also investing in research and development to further enhance the quality and performance of its products. The company is committed to staying at the forefront of technological advancements in the carbide industry, and its R&D efforts are focused on developing new and improved products that meet the evolving needs of its customers."We are excited to announce the expansion of our manufacturing facilities as part of our strategic growth plan," said the spokesperson of Carbide China. "This expansion will allow us to increase our production capacity and meet the growing demand for our high-quality carbide products. We are also investing in research and development to ensure that we continue to offer innovative and reliable solutions to our customers."The expansion of Carbide China's manufacturing facilities is expected to create new job opportunities in the region and contribute to the local economy. The company is committed to supporting the community and providing a safe and productive working environment for its employees. By expanding its operations, Carbide China aims to strengthen its position as a leading provider of carbide products and contribute to the growth and development of the carbide industry.With its expanded manufacturing facilities and ongoing investment in research and development, Carbide China is well-positioned to meet the growing demand for high-quality carbide products in the global market. The company's dedication to excellence, innovation, and customer satisfaction has earned it a strong reputation in the industry, and the expansion of its operations is a testament to its commitment to meeting the needs of its customers.As Carbide China continues to expand its presence in the global market, industry professionals and manufacturers can expect to have access to a wider range of high-quality carbide products that offer precision, durability, and exceptional performance. With its focus on innovation and customer satisfaction, Carbide China is poised to remain a leader in the carbide industry for years to come.

Carbide Mold Industry Sees Shift in Market Demand

Carbide Mold: Revolutionizing the Manufacturing IndustryCarbide molds have emerged as a game-changer in the manufacturing industry, offering advanced precision and durability. As demand for high-quality, complex products continues to grow, the importance of reliable and efficient mold technology cannot be overstated. With the development of carbide molds, manufacturers have achieved significant advancements in their production processes, leading to improved efficiency and product quality.The use of carbide molds has become increasingly popular across a wide range of industries, including automotive, aerospace, electronics, and medical devices. Their ability to withstand high temperatures and pressures, along with their exceptional wear resistance, makes them an ideal choice for the production of complex and intricate parts.One company at the forefront of carbide mold technology is {}. With over [X number of] years of experience in the manufacturing industry, the company has established itself as a leading provider of carbide molds, offering innovative solutions for complex manufacturing challenges.The company's commitment to research and development has led to the creation of a diverse range of carbide mold products, catering to the specific needs of its customers. By leveraging the latest advancements in materials science and engineering, {} has been able to deliver cutting-edge solutions that have revolutionized the manufacturing process for its clients.One of the key factors that sets {} apart from its competitors is its focus on customization. The company works closely with its clients to understand their unique requirements and then develops tailored carbide mold solutions that meet their exact specifications. This approach has enabled {} to build long-standing relationships with its customers, who value the company's commitment to delivering high-quality, reliable products.In addition to its innovative product offerings, {} also provides comprehensive support services to its customers. From initial design and development to ongoing maintenance and support, the company is dedicated to ensuring that its clients get the most out of their carbide mold investments. This level of support has earned {} a reputation for excellence in the industry, further solidifying its position as a trusted partner for manufacturers around the world.As the demand for precision-engineered components continues to rise, the need for advanced mold technology like carbide molds will only continue to grow. With its proven track record of success and a relentless commitment to innovation, {} is well-positioned to play a key role in shaping the future of manufacturing.In conclusion, carbide molds have quickly become a cornerstone of modern manufacturing, offering unparalleled precision and durability. With companies like {} leading the way in developing and delivering advanced carbide mold solutions, the industry is poised to achieve new levels of efficiency and product quality. As manufacturers continue to seek out cutting-edge technologies to meet their production needs, the role of carbide molds will only become more significant, further establishing their place as a crucial component of the manufacturing process.

High-Performance Carbide Wire Roll for Enhanced Durability and Efficiency

Title: Global Manufacturer Launches Revolutionary Carbide Wire Roll for Enhanced Industrial PerformanceIntroduction:In a bid to revolutionize industrial productivity and efficiency, a leading global manufacturer has recently unveiled its groundbreaking YG15 Carbide Wire Roll. Incorporating cutting-edge technology and innovative design, this product promises to significantly improve the performance and longevity of wire rolling processes across various industries worldwide. [A brief company introduction can be included here, highlighting the manufacturer's expertise, global presence, and commitment to delivering high-quality industrial solutions.]Body:1. Overview of YG15 Carbide Wire Roll:The YG15 Carbide Wire Roll is a state-of-the-art wire rolling tool engineered to withstand the most demanding applications. Built with a base material predominantly consisting of tungsten carbide, this revolutionary wire roll exhibits exceptional hardness, wear resistance, and durability, making it a sought-after solution for industries dealing with wire production, coil manufacture, metal forming, and more.2. Key Features and Benefits:a. Unparalleled Durability: The YG15 Carbide Wire Roll boasts extraordinary resistance to wear and abrasion, ensuring a prolonged lifespan and minimization of downtime for maintenance and replacements. This translates into significant cost savings for businesses while maximizing overall productivity.b. Enhanced Precision and Consistency: The precision-engineered design of the carbide roll results in consistently accurate wire diameter control, enabling manufacturers to maintain tight tolerances throughout the production process. This feature is particularly crucial for industries where precision is paramount, such as automotive, aerospace, and electronics.c. Superior Surface Finish: The YG15 Carbide Wire Roll's unique surface finish leads to enhanced wire quality, reducing the need for additional surface treatments. By delivering a smooth and flawless surface, it enables businesses to meet stringent quality standards, while also reducing waste and optimizing operational efficiency.d. Versatility: This innovative wire roll is suitable for various wire rolling applications and can be easily adapted to different machinery setups. Its compatibility with a wide range of wire materials, including stainless steel, carbon steel, copper, and alloy, allows manufacturers to diversify their production capabilities and cater to different market needs.3. Impact on Industries:a. Wire Production: The YG15 Carbide Wire Roll's exceptional durability and precision make it an ideal tool for wire drawing and shaping processes. It enables manufacturers to improve wire quality, reduce surface defects, and enhance productivity, ultimately resulting in enhanced market competitiveness.b. Coil Manufacturing: In the coil manufacturing industry, the YG15 Carbide Wire Roll's ability to maintain consistent wire diameter control fosters the production of evenly wound coils with minimal variations. This leads to increased coil reliability, reduction in scrap, and improved operational efficiency.c. Metal Forming: Industries involved in metal forming processes, such as cold rolling, benefit from the carbide wire roll's outstanding wear resistance. It prolongs the service life of crucial rolling mill components, reduces maintenance costs, and ensures greater operational continuity.4. Future Prospects and Market Adoption:The introduction of the YG15 Carbide Wire Roll marks a significant milestone in the wire processing industry. Its versatile applications, superior performance, and remarkable durability are projected to drive the demand for this innovative product in various industrial sectors around the globe. With this pioneering solution, manufacturers can expect to achieve higher process efficiency, improved product quality, and a competitive edge in today's rapidly evolving markets.Conclusion:The launch of the YG15 Carbide Wire Roll by a leading global manufacturer underscores the company's commitment to delivering cutting-edge solutions that revolutionize industrial practices. With its exceptional durability, precision, and versatility, this innovative wire roll is set to redefine wire rolling processes across multiple industries, offering enhanced performance, increased efficiency, and improved product quality. As the market embraces this groundbreaking technology, manufacturers can confidently propel their operations into a successful and sustainable future.

High-Quality Tungsten Carbide Cold Head Dies for Efficient Cold Forming Processes

Tungsten Carbide Cold Head Dies: The Ultimate Solution for High Precision Fastening ApplicationsIn today's fast-paced manufacturing industry, precision and durability are essential factors for producing high-quality fastening parts. With the increasing demand for reliable and efficient fastening solutions, manufacturers are constantly seeking innovative technologies to enhance their production processes. One such technology that has emerged as a game-changer in the fastening industry is Tungsten Carbide Cold Head Dies.Tungsten Carbide Cold Head Dies are designed to meet the high precision requirements of cold forming processes for fastening applications. These dies are made from high-quality tungsten carbide, a material known for its exceptional hardness, wear resistance, and toughness. This makes Tungsten Carbide Cold Head Dies the ideal choice for producing fastening components with tight tolerances and excellent surface finish.The use of Tungsten Carbide Cold Head Dies offers several advantages over traditional die materials such as steel or ceramic. Tungsten carbide has a much higher hardness and abrasion resistance than steel, allowing the dies to withstand the extreme pressures and forces involved in cold forming operations. This results in longer die life and reduced downtime for die changeovers, leading to improved productivity and cost savings for manufacturers.Furthermore, Tungsten Carbide Cold Head Dies provide superior accuracy and consistency in part dimensions, ensuring that every fastening component meets the required specifications. This is essential for achieving high-quality products and meeting the strict quality standards of industries such as automotive, aerospace, and construction.The company {}, a leading manufacturer of Tungsten Carbide Cold Head Dies, is at the forefront of this innovative technology. With years of experience and expertise in the manufacturing of precision tooling solutions, they have developed a wide range of Tungsten Carbide Cold Head Dies to cater to the diverse needs of the fastening industry.Their Tungsten Carbide Cold Head Dies are meticulously engineered and crafted using advanced manufacturing processes to ensure the highest level of precision and quality. With state-of-the-art facilities and a team of skilled engineers, they are able to deliver custom-designed dies to meet specific customer requirements and applications.In addition to their exceptional product quality, the company also places a strong emphasis on customer service and support. They work closely with their clients to understand their unique production challenges and provide tailored solutions to optimize their cold forming processes. Whether it's improving tool life, enhancing part accuracy, or increasing production efficiency, they are committed to helping their customers achieve their manufacturing goals.Furthermore, the company is dedicated to continuous research and development to further enhance the performance of Tungsten Carbide Cold Head Dies. By investing in new technologies and materials, they are constantly pushing the boundaries of what is achievable in cold forming applications. This unwavering commitment to innovation has cemented their position as a trusted partner for manufacturers seeking reliable and high-performance cold forming tooling solutions.In conclusion, Tungsten Carbide Cold Head Dies have revolutionized the fastening industry with their exceptional hardness, wear resistance, and precision. As the demand for high-quality fastening components continues to grow, manufacturers can rely on the superior performance of Tungsten Carbide Cold Head Dies to meet their production needs. With {}'s expertise and dedication to excellence, they are well-positioned to lead the way in providing cutting-edge tooling solutions for the fastening industry.

Premium Tungsten Carbide Roller: Bringing Unparalleled Polished Finishing

Title: Cutting-Edge Tungsten Carbide Roller Revolutionizes Manufacturing IndustryIntroduction:In our rapidly evolving manufacturing industry, innovation and cutting-edge technology continue to enhance production processes and improve product quality. One such revolutionizing development comes in the form of the Polished Tungsten Carbide Roller, developed by a renowned industry leader (company name).Groundbreaking Technology Enhancing Manufacturing Processes:Tungsten carbide possesses exceptional hardness and resistance to wear, making it an ideal material for manufacturing rollers used in various industries. By incorporating state-of-the-art polishing techniques, the (company name) Polished Tungsten Carbide Roller has taken the performance and efficiency of manufacturing processes to unprecedented heights.Precision and Enhanced Durability:The innovative design of the Polished Tungsten Carbide Roller ensures unparalleled precision, enabling manufacturers to achieve superior results in their production lines. The roller's polished surface significantly reduces friction, resulting in reduced wear and tear. This not only leads to enhanced durability but also extends the product's lifespan, reducing maintenance costs for manufacturers.Versatility Across Industries:The Polished Tungsten Carbide Roller caters to a diverse range of industries, including steel, aluminum, plastic, textile, and paper. Its versatility lies in the roller's ability to withstand extreme environments, high temperatures, corrosive chemicals, and heavy loads. This adaptability ensures that manufacturers can benefit from this groundbreaking technology across various applications.Smoother Operations and Improved Product Quality:With its reduced friction and enhanced durability, the Polished Tungsten Carbide Roller contributes to smoother operations, minimizing downtime and maximizing production efficiency. Its high precision and surface finish guarantee consistent and accurate results, thereby improving product quality and reducing the margin of error.Cost and Energy Efficiency:In addition to its exceptional performance, the Polished Tungsten Carbide Roller also promotes cost and energy efficiency. Its high wear resistance ensures less frequent replacements and maintenance, resulting in reduced operational costs for manufacturers. Additionally, the roller's improved efficiency minimizes energy consumption, making it an environmentally friendly choice.Commitment to Quality Assurance and Safety:As a leader in the manufacturing industry, (company name) prioritizes quality assurance and safety standards. The Polished Tungsten Carbide Roller undergoes rigorous testing and adheres to stringent quality control measures, ensuring that each roller meets or exceeds industry specifications. This commitment to excellence guarantees customer satisfaction and reliable performance for manufacturers in various fields.Global Reach and Customer Satisfaction:Backed by years of research and development, (company name) has built a strong reputation for delivering superior products worldwide. The Polished Tungsten Carbide Roller has garnered positive feedback from clients across the globe, who appreciate the roller's remarkable performance, increased efficiency, and unmatched durability. Customer satisfaction remains at the core of (company name)'s mission, driving them to continually innovate and meet the evolving needs of the industry.Conclusion:The Polished Tungsten Carbide Roller developed by (company name) has emerged as a game-changer in the manufacturing industry, enabling manufacturers to achieve unparalleled precision, efficiency, and durability. Through its innovative design and incorporation of cutting-edge polishing techniques, this revolutionary roller has set new standards for manufacturing processes across a wide range of industries. With its global success and commitment to customer satisfaction, (company name) continues to pave the way for future advancements in the manufacturing industry.

High Performance Tungsten Carbide Roll for Industrial Use

Tungsten carbide, also known as cemented carbide, is a hard material used in many industrial applications. It is made from a powder of tungsten and carbon, which are heated and pressed together to form a solid material. The resulting compound is extremely hard and wear-resistant, making it an ideal material for use in industrial machinery and tools.One company at the forefront of tungsten carbide roll manufacturing is {}. They have recently released their latest product, the YG15X tungsten carbide roll, which is garnering attention in the industry for its high quality and performance.The YG15X tungsten carbide roll is specifically designed for use in the metal forming and wire drawing industries. It is utilized in various machinery and tools to shape and form metal materials, providing precise and consistent results. The roll is engineered to withstand the high pressures and temperatures involved in metal forming processes, making it an essential component for manufacturers in the industry.One of the key factors that sets the YG15X tungsten carbide roll apart from other products on the market is its composition. The roll is made from high-quality tungsten carbide, which is known for its exceptional hardness and strength. This ensures that the roll can withstand heavy wear and tear, providing a longer service life and reducing the need for frequent replacements.In addition to its durability, the YG15X tungsten carbide roll is also designed for superior performance. Its smooth surface finish and precise dimensions ensure a consistent and efficient metal forming process, resulting in higher productivity and less waste. This makes the roll an attractive option for manufacturers looking to improve their operations and reduce costs.Furthermore, the company behind the YG15X tungsten carbide roll has a strong reputation in the industry for producing high-quality products. With years of experience and expertise in tungsten carbide manufacturing, they have gained the trust of their customers by consistently delivering reliable and innovative solutions. Their commitment to product development and customer satisfaction has made them a go-to source for tungsten carbide rolls and other industrial components.Moreover, the company's dedication to quality is reflected in their state-of-the-art manufacturing facilities and rigorous quality control processes. They adhere to strict standards and specifications to ensure that their products meet the highest industry requirements, providing customers with confidence and peace of mind. This attention to detail sets them apart as a leader in the tungsten carbide industry.The release of the YG15X tungsten carbide roll further solidifies the company's position as a frontrunner in the industry. Its advanced features and exceptional performance make it a valuable asset for manufacturers looking to enhance their metal forming processes. With a proven track record of delivering reliable and innovative solutions, customers can trust that the YG15X tungsten carbide roll will meet their needs and exceed their expectations.In conclusion, the YG15X tungsten carbide roll is a cutting-edge product that offers exceptional durability and performance for the metal forming and wire drawing industries. Coupled with the company's expertise and dedication to quality, it is poised to make a significant impact in the industry and provide manufacturers with a valuable tool for their operations. As the demand for high-quality tungsten carbide rolls continues to grow, the YG15X is set to become a go-to solution for manufacturers seeking reliable and efficient metal forming processes.

Discover the Benefits of Coldheading in Manufacturing Processes

Coldheading is a crucial process in the manufacturing industry that is used to form metal parts. This process involves shaping a metal blank at room temperature using high pressure and force to create a desired shape. Coldheading can be done using many different methods, such as extruding, upsetting, and coining.One company that has been leading the way in the coldheading industry is {}. They specialize in providing coldheading solutions for a wide range of industries, including automotive, aerospace, and construction. With state-of-the-art equipment and a team of experienced professionals, they are able to produce high-quality coldheaded parts that meet the strictest industry standards.The process of coldheading begins with the selection of a metal blank, typically made from materials such as steel, aluminum, or brass. The blank is then placed into a coldheading machine, where it is subjected to extreme pressure and force. As the metal is forced into a die, it takes on the shape of the die, resulting in a coldheaded part with precise dimensions and a smooth finish.Coldheading is a highly efficient process that allows for the production of complex parts with minimal material waste. This makes it an ideal solution for the mass production of components such as bolts, screws, and rivets. The coldheading process also results in parts with improved mechanical properties, such as increased strength and durability.In addition to coldheading, {} also offers a range of secondary operations to further enhance the quality and functionality of coldheaded parts. These operations may include heat treatment, plating, and machining, to name a few. This comprehensive approach allows {} to deliver fully finished parts that are ready for use in a variety of applications.With a commitment to innovation and continuous improvement, {} continues to invest in the latest technology and equipment to stay at the forefront of the coldheading industry. Their dedication to quality and precision has earned them a reputation as a reliable partner for businesses seeking coldheaded parts of the highest caliber.One of the key advantages of partnering with {} is their ability to provide customized coldheading solutions to meet the unique needs of their clients. Whether it's a specific material requirement, a complex part design, or a tight production schedule, {} has the expertise and resources to deliver tailored solutions that exceed expectations.In conclusion, coldheading is a critical process in the manufacturing industry that plays a vital role in shaping metal parts for various applications. {} has established itself as a leader in the coldheading industry, offering a comprehensive range of solutions for businesses in diverse sectors. With their commitment to quality, innovation, and customer satisfaction, {} continues to set the standard for excellence in coldheading.

Durable Cemented Carbide Finish Plates for High-Performance Applications

Cemented Carbide Finish Plates are revolutionizing the manufacturing industry with their superior durability and precision. With the increasing demand for high-quality finishing in industrial processes, these plates have become an essential tool for cutting, shaping, and finishing a wide range of materials.The company, located in the heart of the manufacturing hub, has been a leading manufacturer and supplier of cemented carbide products for over 20 years. With a strong focus on research and development, they have continually improved their product offerings to meet the evolving needs of the industry. Their cemented carbide finish plates are a testament to their commitment to innovation and excellence.These finish plates are made from a combination of cemented carbide, a composite material known for its hardness and resistance to wear, and other high-quality materials. This unique combination gives the plates the strength to withstand the most demanding applications while maintaining their precision and accuracy.The finish plates come in a variety of sizes and shapes, making them suitable for a wide range of machining and finishing processes. Whether it's shaping metal parts, cutting intricate designs, or finishing surfaces to a mirror-like polish, these plates deliver exceptional results every time.One of the key advantages of cemented carbide finish plates is their long lifespan. Unlike traditional cutting and finishing tools, these plates have a significantly longer service life, which translates to cost savings for manufacturers. By investing in these plates, companies can reduce their tooling expenses and increase the efficiency of their production processes.Furthermore, the exceptional hardness of cemented carbide makes these finish plates resistant to wear and deformation, ensuring consistent performance over time. This means fewer interruptions for tool changes and adjustments, resulting in increased productivity and overall output.Another notable feature of these finish plates is their precision and accuracy. The company's state-of-the-art manufacturing processes ensure that each plate is crafted to exact specifications, guaranteeing the highest level of precision in every application. This level of accuracy is essential for industries that require tight tolerances and fine finishing, such as aerospace, automotive, and medical device manufacturing.In addition to their durability and precision, cemented carbide finish plates also contribute to environmental sustainability. By lasting longer and requiring fewer replacements, these plates help reduce the amount of material waste generated in manufacturing processes. This aligns with the company's dedication to sustainable and responsible manufacturing practices.The company's commitment to quality and customer satisfaction sets them apart as a trusted provider of cemented carbide finish plates in the industry. Their team of experts works closely with customers to understand their unique needs and provide tailored solutions that deliver exceptional results. From selecting the right plate for a specific application to offering technical support and guidance, the company ensures that its customers are equipped with the best tools for their projects.As industries continue to evolve and demand higher standards of quality and performance, cemented carbide finish plates have emerged as a game-changer in the manufacturing world. With their unmatched durability, precision, and environmental benefits, these plates have become an indispensable asset for companies looking to stay ahead in a competitive market.In conclusion, the company's cemented carbide finish plates are a testament to their commitment to excellence and innovation. By delivering superior products that meet the evolving needs of the industry, they have established themselves as a reliable partner for manufacturers seeking high-quality cutting and finishing solutions. As the demand for advanced manufacturing tools continues to grow, these finish plates are poised to play a pivotal role in shaping the future of the industry.

High-quality Cemented Carbide: Everything You Need to Know

We are excited to announce that the cutting-edge YG15 Cemented Carbide, developed by a leading manufacturer in the industry, is set to revolutionize the world of industrial cutting tools. With its superior durability, precision, and versatility, this innovative material is poised to meet the evolving demands of various applications, offering a more efficient and cost-effective solution for cutting and drilling operations.The YG15 Cemented Carbide is the result of years of research and development by our experienced team of engineers and material scientists. Known for its exceptional hardness and wear resistance, this cemented carbide has been meticulously engineered to deliver unparalleled performance in the most demanding industrial environments. From machining to mining, this advanced material is designed to withstand extreme conditions, providing extended tool life and improved productivity.One of the key advantages of the YG15 Cemented Carbide is its high level of impact resistance, making it particularly well-suited for heavy-duty cutting and drilling tasks. Whether it's milling tough materials or boring through challenging surfaces, this innovative material ensures consistent performance and exceptional tool longevity. By choosing the YG15 Cemented Carbide, industrial professionals can minimize tool wear and reduce the frequency of tool changes, ultimately leading to significant cost savings and increased operational efficiency.In addition to its outstanding mechanical properties, the YG15 Cemented Carbide offers excellent thermal stability, allowing for sustained performance at elevated temperatures. This critical attribute expands the range of applications for which this material is suitable, making it an ideal choice for high-speed machining and other demanding thermal processes. With the YG15 Cemented Carbide, our customers can confidently tackle complex machining tasks with precision and reliability, knowing that their tools can withstand the rigors of the job at hand.Furthermore, the YG15 Cemented Carbide has been engineered to provide exceptional resistance to corrosion and chemical degradation, ensuring long-term performance in aggressive operating environments. This makes it an attractive option for applications in industries such as oil and gas, aerospace, and automotive, where exposure to harsh chemicals and corrosive fluids is common. By choosing tools made with the YG15 Cemented Carbide, our customers can mitigate the effects of corrosion and maintain consistent cutting performance, even in the most challenging conditions.As a leading manufacturer committed to innovation and excellence, we take pride in offering the YG15 Cemented Carbide as part of our comprehensive range of cutting tool solutions. Backed by our extensive expertise and state-of-the-art manufacturing facilities, we are dedicated to delivering products that meet the highest standards of quality, performance, and reliability. Our team is fully equipped to provide tailored solutions to meet the unique needs of our customers, offering technical support and customization services to ensure optimal results.With the introduction of the YG15 Cemented Carbide, we are confident that we are setting a new benchmark for performance and durability in the field of industrial cutting tools. This cutting-edge material represents our ongoing commitment to pushing the boundaries of innovation and delivering tangible value to our customers. We are excited about the potential of the YG15 Cemented Carbide to transform the way cutting and drilling operations are carried out across various industries, and we look forward to supporting our customers in harnessing the full benefits of this advanced material.