High-quality Tungsten Carbide Wire Drawing Die for Smooth and Precise Wire Production

By:Admin

The Tungsten Carbide Wire Drawing Die, developed by the company, is a result of years of research and development in the field of material science and engineering. With a focus on delivering high-performance and durable wire drawing dies, the company has invested in state-of-the-art manufacturing technology and quality control processes to ensure the highest level of precision and reliability in their products.

The Tungsten Carbide Wire Drawing Die manufactured by the company is designed to meet the demanding requirements of wire drawing operations, offering superior performance and longevity. The use of high-quality tungsten carbide material ensures excellent wear resistance, thermal conductivity, and strength, making it an ideal choice for high-speed and high-tension wire drawing processes. Additionally, the company's advanced manufacturing processes enable the production of wire drawing dies with intricate geometries and tight tolerances, allowing for the precise formation of wires with consistent dimensions and surface finish.

Furthermore, the company's commitment to continuous improvement and innovation has led to the development of Tungsten Carbide Wire Drawing Die with enhanced features, including improved die life, reduced wire breakage, and enhanced wire surface quality. These advancements have been well-received by customers in various industries, including automotive, aerospace, electronics, and telecommunications, where the quality and reliability of wire drawing dies are crucial to the overall product performance.

In addition to the superior performance of their Tungsten Carbide Wire Drawing Die, the company also prides itself on providing exceptional customer service and technical support. Their team of experienced engineers and technical experts work closely with customers to understand their specific wire drawing requirements and provide customized solutions to meet their needs. Whether it is developing new die designs, optimizing wire drawing processes, or troubleshooting operational challenges, the company is dedicated to supporting their customers every step of the way.

The company's dedication to quality, innovation, and customer satisfaction has earned them a reputation as a trusted partner in the wire drawing industry. Their Tungsten Carbide Wire Drawing Die has become a preferred choice for manufacturers seeking to improve the efficiency and reliability of their wire drawing operations. With a focus on delivering high-performance products and exceptional customer support, the company continues to set new standards in the wire drawing die industry.

As the demand for high-quality wires continues to grow across various industries, the company remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions that drive the advancement of wire drawing technology. With their Tungsten Carbide Wire Drawing Die at the forefront of wire drawing operations, the company is poised to make a lasting impact on the global wire and cable industry. Their relentless pursuit of excellence and unwavering commitment to customer success position them as a leader in the wire drawing die market.

Company News & Blog

Discover the Advantages of Carbide Inserts for Turning Tasks

Carbide Inserts for Turning Applications: The Future of Machining{Company Name} has recently introduced its newest line of carbide inserts for turning applications. These innovative inserts are designed to meet the demands of various cutting processes, and can be used for machining of many different types of materials. Carbide inserts have long been a preferred option for machining, and the latest product from {Company Name} has set a new standard in the industry.Carbide inserts are perfect for turning applications because they offer superior wear resistance. With their high level of hardness, these inserts can easily handle high-speed turning and continuous cutting processes. The new line of {Company Name} carbide inserts is made from a special grade of carbide that ensures maximum resistance to wear, heat, and corrosion. This unique formulation makes these inserts extremely durable, ensuring a longer tool life and lower operating costs.The new carbide inserts from {Company Name} are designed with specific geometries to improve machining performance. The inserts are also available in a range of coatings that are tailored to various applications. These coatings offer increased wear resistance, and they can provide better chip control and improved surface finish. The coatings are also highly wear-resistant, which helps to prolong the life of the inserts.The new {Company Name} carbide inserts are designed for advanced turning applications, such as finish turning, roughing, and semi-finishing operations. These inserts are also ideal for use in high-speed machining, where precision and reliability are crucial. With their exceptional hardness and wear resistance, {Company Name} carbide inserts can tackle a wide range of materials, including hardened steel, cast iron, and non-ferrous metals."We are proud to introduce our latest line of carbide inserts for turning applications," said the spokesperson from {Company Name}. "These inserts are the result of years of research and development, and we believe that they will set a new standard in the industry. Our carbide inserts offer superior performance in terms of wear resistance and machining performance, and they are designed to meet the demands of even the most challenging cutting processes."{Company Name} has a long track record of providing high-quality machining solutions to its customers. With its latest line of carbide inserts, the company has cemented its position as a leading provider of advanced cutting tools. The carbide inserts are manufactured using the latest technology and machining processes, and they are subjected to rigorous quality control procedures to ensure consistent performance.In addition to its new line of carbide inserts, {Company Name} also offers a range of other cutting tools and accessories. The company's product range includes drills, reamers, milling cutters, and tool holders, among other items. All of these products are designed to meet the demanding needs of modern manufacturing processes, and they are manufactured to the highest standards of quality and durability.Whether you are looking for a solution to improve your machining performance or simply looking for high-quality cutting tools, {Company Name} has the tools you need. The company's team of experts can provide guidance and support in selecting the right tools for your application, ensuring that you get the best possible value for your investment.In conclusion, the new line of carbide inserts from {Company Name} is a game-changer for turning applications. These innovative inserts offer superior wear resistance, machining performance, and durability, making them the go-to option for modern manufacturing processes. With its commitment to quality and customer service, {Company Name} is poised to become the leading provider of advanced cutting tools and accessories in the industry.

High-Quality Tungsten Carbide Pellets for Industrial Applications

Tungsten carbide pellets, also known as Yg22c, have become a crucial component in various industrial applications due to their exceptional hardness, wear resistance, and strength. These pellets are widely used in the production of cutting tools, mining equipment, and wear parts for oil and gas drilling. With the increasing demand for high-quality tungsten carbide pellets, {company name}, a leading manufacturer of tungsten carbide products, has been making significant strides in the industry.Established in {year}, {company name} has established itself as a reliable supplier of tungsten carbide products, offering a wide range of customized solutions to meet the specific requirements of its customers. The company's state-of-the-art manufacturing facilities and advanced technology enable it to produce high-quality tungsten carbide pellets that exceed industry standards.The Yg22c tungsten carbide pellets manufactured by {company name} are known for their superior hardness and toughness, making them highly suitable for demanding applications. These pellets are carefully engineered to provide exceptional wear resistance and thermal stability, allowing them to withstand heavy-duty operations in various industries. Additionally, {company name} ensures that its tungsten carbide pellets are produced with precision and consistency, resulting in products of unmatched quality.In addition to its commitment to product excellence, {company name} places a strong emphasis on environmental sustainability and ethical business practices. The company adheres to strict environmental standards in its manufacturing processes, minimizing its carbon footprint and promoting responsible use of resources. Furthermore, {company name} is dedicated to maintaining a safe and healthy work environment for its employees, ensuring compliance with all relevant occupational health and safety regulations.With a focus on innovation and continuous improvement, {company name} continues to invest in research and development to enhance its product offerings and meet the evolving needs of its customers. The company's team of skilled engineers and technical experts work diligently to develop cutting-edge solutions that deliver superior performance and reliability. By staying at the forefront of technological advancements, {company name} remains at the forefront of the tungsten carbide industry.The success of {company name} can be attributed to its unwavering commitment to customer satisfaction. The company places a strong emphasis on building lasting partnerships with its clients, understanding their unique requirements, and delivering tailored solutions that exceed expectations. With a customer-centric approach, {company name} has earned a stellar reputation for its reliability, professionalism, and integrity in the industry.As the demand for high-quality tungsten carbide pellets continues to grow, {company name} remains poised to meet the needs of its customers and lead the way in the industry. The company's dedication to excellence, innovation, and sustainability sets it apart as a trusted provider of tungsten carbide solutions, ensuring its continued success and growth in the market.In conclusion, {company name}'s Yg22c tungsten carbide pellets represent the pinnacle of quality and performance in the industry. With a focus on excellence, sustainability, and customer satisfaction, the company continues to set the standard for tungsten carbide products, solidifying its position as a leader in the market. With its unwavering commitment to innovation and quality, {company name} is well-positioned to meet the evolving needs of its customers and maintain its prominence in the industry for years to come.

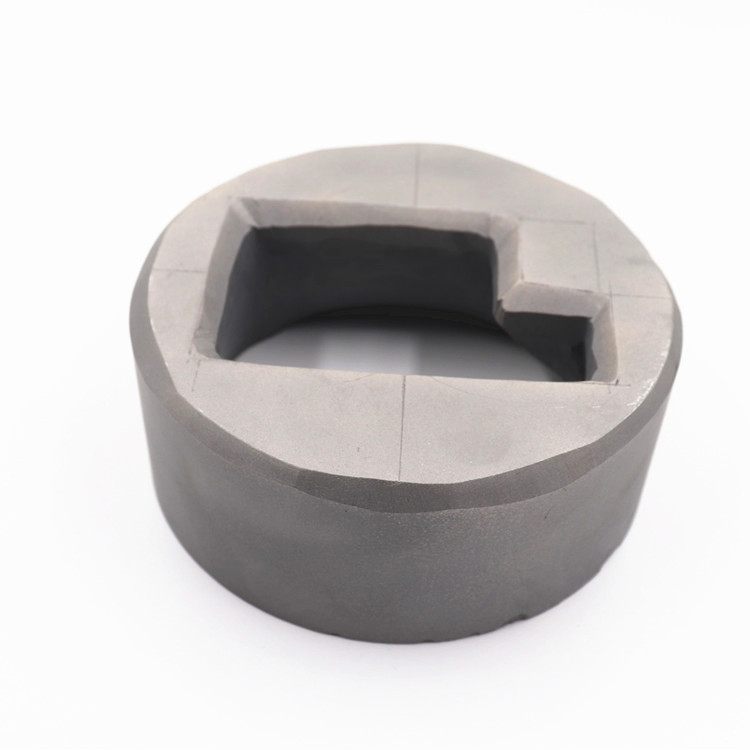

High-Quality Tungsten Carbide Molding Dies for Precision Manufacturing

Tungsten Carbide Molding Dies revolutionize the manufacturing industry with their exceptional durability and precision. These innovative tools are at the forefront of the industry, offering a wide range of applications for various manufacturing processes. One of the leading companies at the forefront of this technology is {company}, a global leader in the development and production of high-quality tungsten carbide molding dies.{Company} has been a key player in the manufacturing industry for over 30 years, specializing in the production of tungsten carbide products. Their expertise in this area has allowed them to develop cutting-edge molding dies that have set new standards for quality and performance.Tungsten carbide is a composite material composed of tungsten carbide particles held together by a metal binder, typically cobalt. This unique combination of materials gives tungsten carbide molding dies their exceptional hardness and wear resistance, making them ideal for use in high-stress manufacturing environments.One of the primary uses of tungsten carbide molding dies is in the production of metal and plastic components through the process of cold-heading and cold-forming. These dies are essential for shaping and forming materials such as steel, aluminum, and copper with precision and efficiency. The superior hardness and wear resistance of tungsten carbide ensure that these dies maintain their cutting edge and dimensional accuracy over prolonged use, resulting in higher productivity and reduced downtime for manufacturers.In addition to cold-heading and cold-forming applications, tungsten carbide molding dies are also widely used in the production of ceramics, glass, and other non-metallic materials. The exceptional hardness and thermal conductivity of tungsten carbide make it an ideal material for shaping and forming these materials with a high degree of precision.{Company} has been at the forefront of developing custom tungsten carbide molding dies to meet the specific needs of their clients. Their team of experienced engineers and technicians work closely with customers to design and produce dies that are tailored to their unique specifications and requirements. This level of customization has enabled {company} to establish itself as a trusted partner for manufacturers in a wide range of industries, including automotive, aerospace, medical, and consumer goods.The commitment to quality and innovation at {company} is evident in their state-of-the-art manufacturing facilities, where the latest technology and advanced equipment are employed to produce tungsten carbide molding dies of the highest caliber. Stringent quality control measures are implemented at every stage of the production process to ensure that the dies meet the strictest standards for performance and durability.Furthermore, {company} places a strong emphasis on research and development to stay ahead of the curve in the rapidly evolving manufacturing industry. Their investment in cutting-edge technologies and continuous improvement initiatives has led to the development of new and innovative solutions that push the boundaries of what is possible with tungsten carbide molding dies.The impact of tungsten carbide molding dies on the manufacturing industry cannot be overstated. Their exceptional durability, precision, and versatility have made them an indispensable tool for manufacturers seeking to improve their productivity and product quality. As a leading manufacturer of these groundbreaking tools, {company} continues to drive innovation and set new benchmarks for excellence in the industry.In conclusion, tungsten carbide molding dies represent a significant advancement in the manufacturing industry. Their exceptional durability, precision, and versatility make them an essential tool for a wide range of applications, from cold-heading and cold-forming to the production of non-metallic materials. {Company} stands at the forefront of this technology, leveraging their expertise and state-of-the-art facilities to produce high-quality tungsten carbide molding dies that meet the unique needs of their clients. With a commitment to innovation and continuous improvement, {company} is poised to lead the way in shaping the future of manufacturing with tungsten carbide molding dies.

Top 10 Benefits of Using a Content Mill Roller for Your Business

[Company Name] Unveils New State-of-the-Art Mill Roller Technology[City, Date] - [Company Name], a global leader in the manufacturing of industrial equipment, has recently launched its latest innovation in mill roller technology. The new state-of-the-art mill roller is set to revolutionize the milling industry by offering improved efficiency, performance, and productivity.With over [number] years of experience in the industry, [Company Name] has built a reputation for delivering cutting-edge solutions that meet the evolving needs of its customers. The company's commitment to innovation and excellence is evident in the development of its new mill roller technology.The new mill roller is designed to enhance the milling process by providing a more consistent and efficient grinding performance. Its advanced design features ensure that the mill roller can handle a wide range of materials with precision and accuracy, resulting in higher quality output and reduced maintenance requirements.In addition to its superior performance, the new mill roller also offers enhanced durability and longevity. The use of high-quality materials and precision engineering ensures that the mill roller can withstand the rigors of heavy-duty milling operations, reducing downtime and maintenance costs for customers.Furthermore, the new mill roller incorporates advanced technology to optimize energy efficiency and minimize environmental impact. By reducing energy consumption and emissions, [Company Name] is helping its customers operate more sustainably and responsibly, aligning with the growing trend towards environmentally-friendly manufacturing practices."We are thrilled to introduce our latest innovation in mill roller technology," said [Company Name]'s CEO. "Our new mill roller is the result of extensive research, development, and testing, and we are confident that it will deliver significant benefits to our customers. This is a testament to our ongoing commitment to excellence and our dedication to driving innovation in the industry."The new mill roller technology is now available for customers globally, and [Company Name] has already received positive feedback from early adopters. The company is also offering comprehensive support and after-sales service to ensure that customers can maximize the benefits of the new technology.In addition to its latest mill roller, [Company Name] offers a comprehensive range of industrial equipment, including crushers, screens, and conveyors, serving various industries such as mining, construction, and aggregate processing. The company's products are renowned for their quality, reliability, and performance, and are trusted by customers around the world.[Company Name] is also committed to ongoing research and development to continue pushing the boundaries of innovation in industrial equipment. The company's dedicated team of engineers and technical experts are constantly exploring new technologies and solutions to address the evolving needs of its customers and the industry as a whole.As the industry continues to evolve, [Company Name] remains at the forefront of innovation, delivering advanced solutions that empower its customers to achieve new levels of productivity, efficiency, and sustainability. With its latest mill roller technology, the company is set to further solidify its position as a leading provider of industrial equipment and a trusted partner for businesses worldwide.For more information about [Company Name] and its latest mill roller technology, please visit [company website].

Ultimate Guide to YG6 Tungsten Carbide: Uses and Properties Revealed

In the fast-paced world of manufacturing and industrial production, having access to high-quality cutting tools and wear-resistant components is essential for maintaining efficiency and productivity. This is where the importance of tungsten carbide comes into play. YG6, a type of tungsten carbide, has quickly become a preferred choice for many companies due to its exceptional hardness, strength, and durability. When combined with the innovative manufacturing capabilities of {Company}, the result is a winning combination that is setting new standards in the industry.{Company} has established itself as a leading producer of precision components and tooling solutions, with a focus on delivering top-quality products to a diverse range of industries, including automotive, aerospace, defense, and more. The company's commitment to excellence and continuous improvement has made it a trusted partner for many businesses seeking advanced solutions for their manufacturing needs. By leveraging cutting-edge technology and a team of experienced professionals, {Company} has positioned itself at the forefront of the industry, constantly pushing the boundaries of what is possible in terms of product performance and quality.One of the key factors that sets {Company} apart from the competition is its ability to work with materials like tungsten carbide, particularly the YG6 grade. Tungsten carbide is a composite material that is made up of tungsten and carbon atoms, resulting in an exceptionally hard and wear-resistant material that is ideal for use in a variety of industrial applications. YG6 tungsten carbide, in particular, is known for its high strength, excellent wear resistance, and versatility, making it an ideal choice for cutting tools, dies, punches, and other components that are subjected to high levels of wear and abrasion.When {Company} combines its expertise in manufacturing with the exceptional properties of YG6 tungsten carbide, the result is a range of products that are unmatched in terms of performance and reliability. Whether it's precision cutting tools, wear-resistant components, or specialized tooling solutions, {Company}'s utilization of YG6 tungsten carbide ensures that its customers receive products that not only meet but exceed their expectations.A key advantage of YG6 tungsten carbide is its ability to maintain its hardness and strength even under the most demanding conditions. This means that components and tools made from YG6 tungsten carbide are able to withstand high levels of wear and abrasion, resulting in extended tool life, reduced downtime, and lower maintenance costs for industrial operations. This level of durability and reliability is particularly valuable in industries where precision and consistency are critical to success.Additionally, YG6 tungsten carbide also offers excellent resistance to heat, corrosion, and chemical damage, further enhancing its suitability for use in challenging environments. As a result, components and tools made from YG6 tungsten carbide are able to maintain their performance and integrity over extended periods of use, providing long-term value and cost savings for businesses.By leveraging the unique properties of YG6 tungsten carbide, {Company} is able to provide its customers with solutions that are tailored to their specific needs and requirements. This includes custom-designed cutting tools, wear-resistant components, and other specialized products that are engineered to deliver optimal performance and reliability in the most demanding applications. Whether it's a complex machining operation, a high-volume production process, or a specialized manufacturing task, {Company}'s use of YG6 tungsten carbide ensures that its customers have access to the best possible solutions for their needs.In conclusion, the combination of {Company}'s innovative manufacturing capabilities with the exceptional properties of YG6 tungsten carbide is a winning formula that is driving new standards in the industry. By delivering products that offer unparalleled hardness, strength, and durability, {Company} is helping its customers achieve new levels of performance and efficiency in their operations. As industries continue to evolve and demand higher levels of precision and reliability, the partnership between {Company} and YG6 tungsten carbide is poised to play a key role in shaping the future of manufacturing and industrial production.

Durable Carbide Bushing for Long-Lasting Performance

Carbide Bushing, a leading manufacturer of high-quality industrial components, has been making waves in the industry with their innovative and reliable products. The company, founded in 1989, has built a solid reputation for delivering top-notch carbide bushings and other related products to a wide range of sectors, including automotive, aerospace, oil and gas, and manufacturing.One of the key strengths of Carbide Bushing is their unwavering commitment to quality. The company has invested heavily in research and development to ensure that their products meet the highest standards of precision and durability. This dedication to excellence has earned them the trust of customers around the world, who rely on Carbide Bushing's products to keep their operations running smoothly.In addition to their focus on quality, Carbide Bushing also stands out for their versatility. The company offers a wide range of carbide bushing products, including solid carbide bushings, ceramic carbide bushings, and custom-designed solutions to meet the unique needs of their clients. This flexibility allows Carbide Bushing to serve a diverse customer base and provide tailored solutions for even the most challenging applications.Furthermore, Carbide Bushing is committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes, including the use of recycled materials and energy-efficient technologies. By prioritizing sustainability, Carbide Bushing not only reduces their environmental impact but also sets an example for the industry as a whole.Recently, Carbide Bushing introduced a new line of carbide bushings that have been met with great enthusiasm from their customers. These innovative products incorporate the latest advancements in materials and manufacturing techniques to deliver superior performance and longevity. With these new offerings, Carbide Bushing continues to solidify their position as a leader in the industry and a go-to source for high-quality carbide bushings.One of the most notable features of Carbide Bushing's new products is their enhanced resistance to wear and corrosion. The company has leveraged their extensive expertise in materials science to develop carbide bushings that can withstand the harshest operating conditions, including high temperatures, heavy loads, and corrosive chemicals. This improved durability translates to longer service life and reduced maintenance costs for their customers, making Carbide Bushing's products an excellent investment for any industrial application.Furthermore, Carbide Bushing has incorporated advanced manufacturing technologies into their production processes to ensure the highest level of precision and consistency in their products. Through the use of state-of-the-art machinery and quality control measures, the company is able to deliver carbide bushings that meet the most demanding specifications and exceed customer expectations.In addition to their technical prowess, Carbide Bushing also prides itself on providing excellent customer service. The company's team of knowledgeable and experienced professionals is dedicated to understanding their clients' needs and offering personalized support to help them find the right solutions for their specific requirements. This commitment to customer satisfaction has earned Carbide Bushing a loyal and satisfied customer base, who appreciate the company's reliability and responsiveness.Looking ahead, Carbide Bushing is poised to continue their legacy of excellence in the industry. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of the market and maintain their leadership in the carbide bushing industry. By staying true to their core values and continuing to push the boundaries of what is possible, Carbide Bushing is set to remain a trusted partner for companies seeking top-quality industrial components.

Top Suppliers of Tungsten Carbide in China - A Comprehensive Guide

Tungsten carbide is a compound consisting of tungsten and carbon, known for its exceptional hardness and resistance to wear and corrosion. It is widely used in various industries, including mining, construction, and manufacturing. Chinese manufacturer {} is a leading producer of tungsten carbide products, offering a wide range of high-quality tools and wear parts to customers around the world.Founded in 2006, {} has quickly established itself as a reliable and innovative supplier in the tungsten carbide industry. The company's state-of-the-art manufacturing facilities are equipped with advanced production technology and precision machining equipment, allowing them to produce high-performance tungsten carbide products with tight tolerances and excellent surface finishes. {}'s dedication to quality and customer satisfaction has earned them a solid reputation in the global market.One of the key advantages of {} is its strong R&D capabilities. The company has a team of experienced engineers and material scientists who are constantly developing new grades of tungsten carbide to meet the evolving needs of different industries. By investing in research and development, {} stays at the forefront of technology and innovation, ensuring that their products are always at the cutting edge of performance and reliability.In addition to standard tungsten carbide products such as inserts, rods, and drill bits, {} also offers customized solutions to meet specific customer requirements. Whether it's a unique shape, special composition, or tailored surface treatment, {}'s engineering team works closely with clients to develop bespoke tungsten carbide solutions that deliver optimal performance and cost-effectiveness.With a strong commitment to sustainability, {} places a high priority on environmental protection and energy efficiency in its production processes. The company adheres to strict environmental regulations and implements green practices to minimize waste and emissions, ensuring that its operations are as environmentally friendly as possible. In addition, {} actively promotes the recycling of tungsten carbide scrap, contributing to the conservation of resources and the reduction of carbon footprint.In recent years, {} has been expanding its presence in international markets, building a global distribution network to serve customers in Europe, North America, and Asia. By establishing strategic partnerships with local distributors and agents, the company has been able to provide timely and efficient support to its overseas clients, further enhancing its reputation as a trusted supplier of high-quality tungsten carbide products.As part of its growth strategy, {} is continuously exploring new opportunities for business development and collaboration. The company actively participates in industry exhibitions and trade fairs, where it showcases its latest products and technologies, and engages with potential partners and customers. By staying connected to the market and fostering relationships with industry stakeholders, {} seeks to expand its reach and strengthen its position as a leading player in the global tungsten carbide market.Looking ahead, {} is poised to continue its success story in the tungsten carbide industry. With a solid foundation of technical expertise, manufacturing capabilities, and market presence, the company is well-positioned to capitalize on the growing demand for high-performance wear-resistant materials in various industrial applications. By staying true to its core values of quality, innovation, and sustainability, {} is set to remain a preferred choice for customers seeking reliable tungsten carbide solutions.

High-quality Cemented Carbide Strips for Various Applications

Cemented Carbide Strips have been a vital component in various industries including manufacturing, automotive, aerospace, and mining. These strips are widely used for their high hardness, exceptional wear resistance, and strength, making them an essential material for tools and equipment in demanding applications. One company that has been at the forefront of producing high-quality Cemented Carbide Strips is {}.{} has a long-standing reputation for manufacturing top-of-the-line cemented carbide products. With a strong focus on research and development, the company has been consistently delivering innovative solutions to meet the evolving demands of its customers. By leveraging advanced technologies and a team of skilled engineers, {} has been able to create Cemented Carbide Strips that offer superior performance and durability.The company's Cemented Carbide Strips are designed to withstand extreme conditions, making them suitable for a wide range of applications. Whether it's cutting, drilling, milling, or wear protection, {}'s cemented carbide strips are known for their high precision and reliability. The company offers a variety of grades and sizes to cater to different customer requirements, ensuring that they can provide the right solution for any application.One of the key factors that set {} apart from its competitors is its commitment to quality. The company follows stringent quality control measures at every stage of the manufacturing process to ensure that its Cemented Carbide Strips meet the highest standards. From the selection of raw materials to the final inspection of the finished products, {} maintains a rigorous quality assurance system to guarantee the reliability and performance of its cemented carbide strips.In addition to quality, {} also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and provide tailored solutions that meet their requirements. Whether it's customizing the dimensions of the strips or developing new grades to address specific challenges, {} is dedicated to delivering personalized solutions that add value to its customers' operations.With a strong global presence, {} has been able to serve a diverse customer base across different industries. The company's Cemented Carbide Strips have earned a reputation for their consistency and performance, making them a preferred choice for many leading companies around the world. Whether it's a small-scale workshop or a large industrial corporation, {} has the capability to meet the demands of any customer, regardless of their size or location.Looking ahead, {} continues to invest in research and development to further enhance its product offerings. The company is constantly exploring new technologies and materials to improve the performance of its Cemented Carbide Strips and stay ahead of market trends. By staying at the forefront of innovation, {} aims to solidify its position as a trusted provider of high-quality cemented carbide solutions.In conclusion, {} has established itself as a reliable and innovative manufacturer of Cemented Carbide Strips. With a focus on quality, customer satisfaction, and continuous improvement, the company has been able to meet the evolving needs of its customers and deliver superior products that excel in demanding applications. As the demand for high-performance materials continues to grow, {} is well-positioned to remain a leading player in the cemented carbide industry.

High-Quality Carbide Drawing Die Factory - All You Need to Know

Carbide Drawing Die Factory Leads the Industry in Innovation and QualityCarbide drawing die factory, a leading producer of carbide drawing dies for the wire and cable industry, has been making waves in the industry with its innovative products and commitment to quality. With a rich history in the industry and a dedication to customer satisfaction, the company has become a trusted name in the production of high-quality drawing dies.The company, based in [location], has been in operation for over [number] years, establishing itself as a top producer in the industry. Specializing in the manufacture of carbide drawing dies, the company has gained a reputation for delivering products that meet the highest standards of quality and performance.Known for its commitment to innovation, the company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By continuously improving its manufacturing processes and materials, the company is able to produce drawing dies that are both durable and efficient, meeting the evolving needs of its clients.One of the key factors that sets the company apart from its competitors is its focus on customer satisfaction. The company understands the importance of building strong relationships with its clients and works closely with them to understand their specific needs and requirements. This customer-centric approach has led to the development of custom solutions that address the unique challenges faced by different businesses in the wire and cable industry.In addition to its commitment to quality and innovation, the company also prioritizes sustainability in its operations. By adhering to strict environmental standards and implementing sustainable practices, the company ensures that its manufacturing processes have minimal impact on the environment. This dedication to sustainability has not only helped the company reduce its carbon footprint but has also resonated with its environmentally conscious clients.The company's dedication to quality and innovation has not gone unnoticed, as it has received numerous accolades and certifications for its performance in the industry. These recognitions serve as a testament to the company's unwavering commitment to excellence and its position as a leader in the production of carbide drawing dies.Looking ahead, the company remains focused on its mission to provide high-quality drawing dies that meet the ever-evolving demands of the wire and cable industry. By continuing to invest in research and development and maintaining its customer-centric approach, the company is poised to remain a driving force in the industry for years to come.In conclusion, carbide drawing die factory has established itself as a leading producer of high-quality drawing dies, known for its innovation, commitment to quality, and dedication to customer satisfaction. With a long-standing history in the industry and a focus on sustainability, the company continues to set the bar for excellence in the production of carbide drawing dies, ensuring that it remains a trusted partner for businesses in the wire and cable industry.

Advanced technology for cold forging die production and development

HSS (High-Speed Steel) cold forging dies are an integral part of the manufacturing process in the automotive, aerospace, and construction industries. These dies are used to shape and form metal components with high precision and accuracy, making them essential for ensuring the quality and reliability of the final products.One company that has been at the forefront of producing high-quality HSS cold forging dies is [company name]. With years of experience and expertise in the field of metalworking and tooling, [company name] has established itself as a leading manufacturer of cold forging dies that are known for their durability, precision, and efficiency.The company's commitment to excellence and innovation has led to the development of a wide range of HSS cold forging dies that cater to diverse industry needs. These dies are designed to withstand high-temperature and high-pressure conditions, making them suitable for shaping and forming a variety of metals, including steel, aluminum, and titanium. The advanced materials and precision engineering used in the manufacturing of these dies ensure that they deliver consistent and reliable performance, resulting in high-quality finished products.In addition to its extensive range of standard HSS cold forging dies, [company name] also offers customized die solutions to meet specific customer requirements. The company's team of skilled engineers and technicians work closely with clients to understand their unique needs and design dies that are tailored to their exact specifications. This flexibility and customer-centric approach have made [company name] a trusted partner for many leading companies across different industries.Furthermore, [company name] is committed to staying ahead of the curve when it comes to technological advancements and manufacturing processes. The company invests in state-of-the-art equipment and machinery to ensure that its HSS cold forging dies are produced with the highest level of precision and efficiency. This commitment to continuous improvement has enabled [company name] to stay competitive in the global market and maintain its reputation as a leader in the tooling industry.Moreover, [company name] places a strong emphasis on quality control and assurance throughout the manufacturing process. Rigorous testing and inspection procedures are implemented to ensure that every HSS cold forging die meets the company's strict quality standards before it is released to the market. This dedication to quality has earned [company name] the trust and confidence of its customers, who rely on the company's products to deliver exceptional performance and reliability.In conclusion, [company name] stands out as a leading manufacturer of HSS cold forging dies, offering a comprehensive range of standard and customized die solutions to meet the diverse needs of its customers. With a focus on quality, innovation, and customer satisfaction, [company name] continues to set the benchmark for excellence in the tooling industry. As the demand for high-quality metal components continues to grow, [company name] is well-positioned to meet the evolving needs of the market and maintain its leadership in the production of HSS cold forging dies.