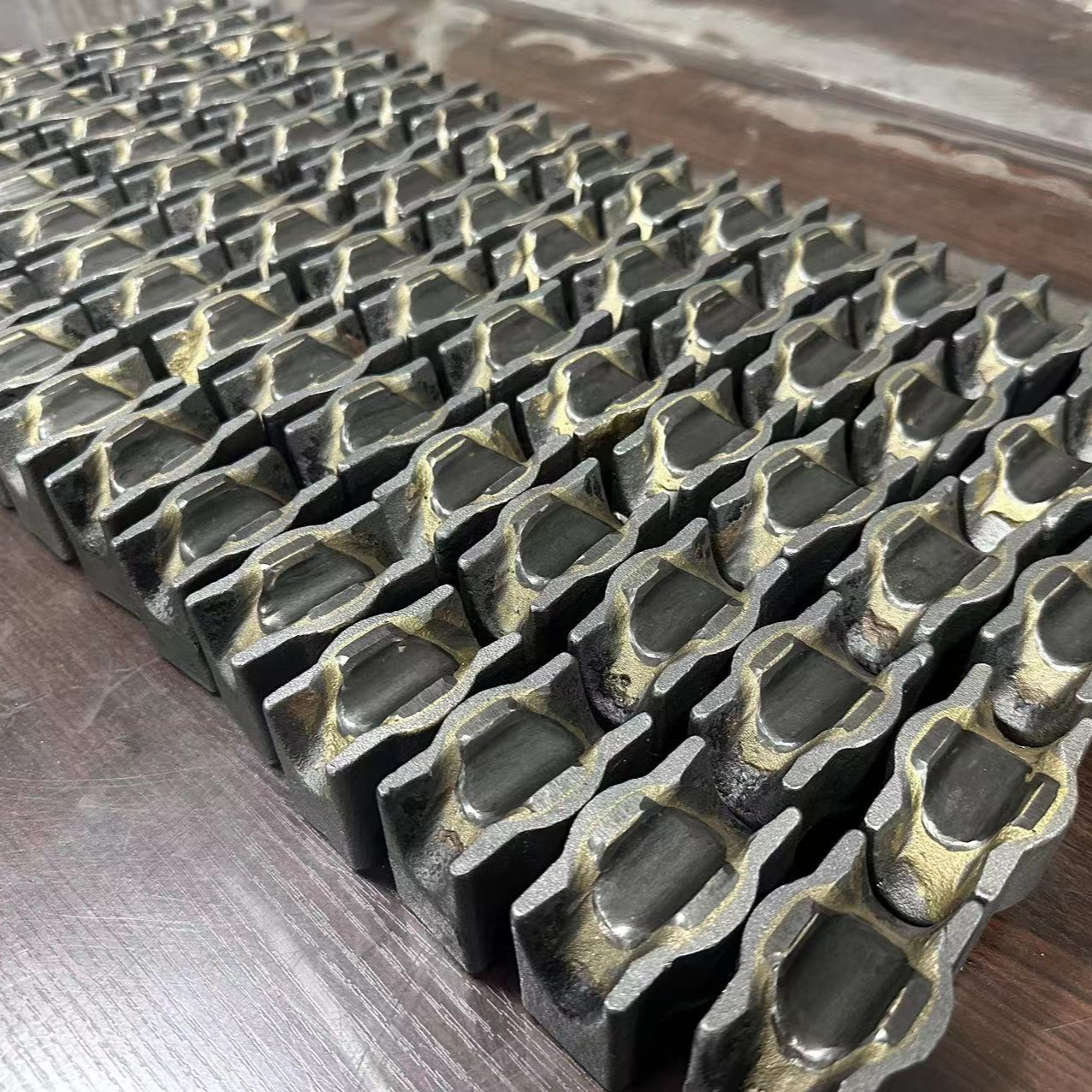

High quality Cemented Carbide Drawing Die for industrial use

By:Admin

Established in {}, {} has been at the forefront of cemented carbide technology, providing high-quality products and services to a wide range of industries including automotive, aerospace, electronics, and more. With a strong focus on research and development, the company has continuously pushed the boundaries of innovation, leading to the creation of cutting-edge products such as the new Cemented Carbide Drawing Die.

The new line of Cemented Carbide Drawing Die from {} boasts several key features that set it apart from traditional die products. One of the most notable features is its exceptional hardness and wear resistance, which ensures longevity and durability in the manufacturing process. This means that customers can expect reduced downtime and maintenance costs, ultimately leading to increased productivity and cost savings.

In addition to its superior hardness, the new Cemented Carbide Drawing Die also offers excellent dimensional stability, ensuring precise and consistent product quality. This is particularly important in industries where tight tolerances and high-quality finishes are essential. With {}’s new die products, manufacturers can achieve exceptional surface finishes and dimensional accuracy, meeting the stringent requirements of their customers.

Furthermore, the new line of Cemented Carbide Drawing Die is designed for versatility, capable of handling a wide range of materials and applications. Whether it's drawing copper, aluminum, steel, or other alloys, {}’s die products can effectively and efficiently process various materials, making them an ideal choice for diverse manufacturing needs.

To complement its innovative products, {} also offers comprehensive technical support and consultation services to its customers. With a team of experienced engineers and technicians, the company is committed to providing tailored solutions to address specific manufacturing challenges. From die design and selection to troubleshooting and optimization, {}’s technical experts work closely with customers to ensure the seamless integration of its products into their production processes.

With the introduction of its new line of Cemented Carbide Drawing Die, {} is poised to further solidify its position as a leading provider of cemented carbide solutions. By leveraging its expertise in material science and manufacturing technology, the company continues to drive innovation and deliver value to its customers across the globe.

In conclusion, the unveiling of {}’s new Cemented Carbide Drawing Die represents a significant milestone in the advancement of cemented carbide technology. With its exceptional hardness, dimensional stability, and versatility, the new die products are set to raise the bar for manufacturing excellence. Coupled with the company’s dedication to technical support and customer satisfaction, {} is well-positioned to meet the evolving needs of the industry and empower manufacturers to achieve new heights of success.

Company News & Blog

High-quality Cemented Carbide Strips for Various Applications

Cemented Carbide Strips have been a vital component in various industries including manufacturing, automotive, aerospace, and mining. These strips are widely used for their high hardness, exceptional wear resistance, and strength, making them an essential material for tools and equipment in demanding applications. One company that has been at the forefront of producing high-quality Cemented Carbide Strips is {}.{} has a long-standing reputation for manufacturing top-of-the-line cemented carbide products. With a strong focus on research and development, the company has been consistently delivering innovative solutions to meet the evolving demands of its customers. By leveraging advanced technologies and a team of skilled engineers, {} has been able to create Cemented Carbide Strips that offer superior performance and durability.The company's Cemented Carbide Strips are designed to withstand extreme conditions, making them suitable for a wide range of applications. Whether it's cutting, drilling, milling, or wear protection, {}'s cemented carbide strips are known for their high precision and reliability. The company offers a variety of grades and sizes to cater to different customer requirements, ensuring that they can provide the right solution for any application.One of the key factors that set {} apart from its competitors is its commitment to quality. The company follows stringent quality control measures at every stage of the manufacturing process to ensure that its Cemented Carbide Strips meet the highest standards. From the selection of raw materials to the final inspection of the finished products, {} maintains a rigorous quality assurance system to guarantee the reliability and performance of its cemented carbide strips.In addition to quality, {} also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and provide tailored solutions that meet their requirements. Whether it's customizing the dimensions of the strips or developing new grades to address specific challenges, {} is dedicated to delivering personalized solutions that add value to its customers' operations.With a strong global presence, {} has been able to serve a diverse customer base across different industries. The company's Cemented Carbide Strips have earned a reputation for their consistency and performance, making them a preferred choice for many leading companies around the world. Whether it's a small-scale workshop or a large industrial corporation, {} has the capability to meet the demands of any customer, regardless of their size or location.Looking ahead, {} continues to invest in research and development to further enhance its product offerings. The company is constantly exploring new technologies and materials to improve the performance of its Cemented Carbide Strips and stay ahead of market trends. By staying at the forefront of innovation, {} aims to solidify its position as a trusted provider of high-quality cemented carbide solutions.In conclusion, {} has established itself as a reliable and innovative manufacturer of Cemented Carbide Strips. With a focus on quality, customer satisfaction, and continuous improvement, the company has been able to meet the evolving needs of its customers and deliver superior products that excel in demanding applications. As the demand for high-performance materials continues to grow, {} is well-positioned to remain a leading player in the cemented carbide industry.

Durable and Long-Lasting Carbide Plate for Industrial Use

Carbide Plate Revolutionizes Industrial Manufacturing: A Look at its ImpactThe use of carbide plates in industrial manufacturing has revolutionized the way companies produce high-quality products. {Company name} is at the forefront of this technology, offering a range of carbide plates that have been highly sought after in the industry. With their innovative approach to developing high-performance carbide plates, {Company name} has improved the efficiency and quality of manufacturing processes across various sectors.Carbide plates are essential components in industrial manufacturing as they are known for their hardness, wear resistance, and high melting point. This makes them ideal for use in cutting tools, abrasives, and wear applications. {Company name} has taken this to the next level by developing carbide plates that are not only durable but also highly versatile. Their products have been used in a wide range of applications, from aerospace and automotive to oil and gas industries.One of the key features of {Company name}'s carbide plates is their exceptional strength and durability. This has allowed manufacturers to produce high-quality products with precision and consistency. The wear resistance of the carbide plates ensures that the cutting tools and wear applications maintain their sharpness and effectiveness over extended periods. This has resulted in a significant reduction in downtime for maintenance and tool replacement, leading to increased productivity and cost savings for manufacturers.Furthermore, {Company name} has focused on developing carbide plates that are highly versatile and can be used in various manufacturing processes. This versatility has been a game-changer for many companies, as it has allowed them to streamline their production processes and reduce the need for multiple tooling setups. This has not only simplified manufacturing operations but has also led to significant improvements in product quality and consistency.The impact of {Company name}'s carbide plates on the industry has been profound, with many manufacturers experiencing a significant improvement in their production capabilities. By using these high-performance carbide plates, companies have been able to push the boundaries of what is possible in industrial manufacturing. From producing intricate components for aerospace applications to manufacturing high-precision parts for the automotive industry, {Company name} has played a crucial role in enabling manufacturers to achieve new levels of efficiency and quality.In addition to their exceptional product offerings, {Company name} has also set itself apart through its commitment to customer satisfaction. Their team of experts works closely with clients to understand their specific needs and provide tailored solutions that meet their requirements. This level of personalized service has been instrumental in establishing {Company name} as a trusted partner for many manufacturers looking to enhance their production processes.Looking ahead, {Company name} is dedicated to furthering the development of carbide plates and other cutting-edge materials to support the evolving needs of the industry. By investing in research and development, they aim to continue pushing the boundaries of what is possible in industrial manufacturing. This commitment to innovation and excellence positions {Company name} as a leader in the field, with a bright future ahead.Overall, the impact of carbide plates in industrial manufacturing cannot be overstated. With {Company name} leading the charge in developing high-performance carbide plates, manufacturers have been able to achieve new levels of efficiency, precision, and quality in their production processes. As the industry continues to evolve, it is clear that carbide plates will play a pivotal role in shaping the future of manufacturing.

High-quality Tungsten Carbide Blank for YG15X Material

Tungsten carbide is a material known for its exceptional hardness and wear resistance, making it an ideal choice for a wide range of industrial applications. This remarkable material is used in the production of cutting tools, wear parts, and other critical components in industries such as aerospace, automotive, and mining. As the demand for high-quality tungsten carbide blanks continues to grow, the need for reliable suppliers becomes increasingly important.One company that has built a strong reputation as a leading provider of tungsten carbide blanks is {} (company name). With a commitment to quality and innovation, {} has established itself as a trusted source for high-performance carbide solutions. The company's dedication to excellence is exemplified by its latest product offering, the YG15X tungsten carbide blank.The YG15X tungsten carbide blank is a premium-grade material designed to meet the most demanding requirements of modern industrial applications. Composed of tungsten and carbon atoms in a tough cobalt matrix, this carbide blank exhibits exceptional hardness and wear resistance. The YG15X blank is specifically engineered to withstand the most challenging machining and cutting tasks, making it an ideal choice for manufacturers seeking reliable and high-performance tooling solutions.One of the key features of the YG15X tungsten carbide blank is its superior toughness and impact resistance. This allows it to maintain its cutting edge and dimensional stability even in the most demanding working environments. Whether it's cutting, milling, or drilling, the YG15X blank delivers consistent performance and extended tool life, ultimately resulting in improved productivity and cost savings for end users.In addition to its outstanding mechanical properties, the YG15X tungsten carbide blank is also highly resistant to heat and corrosion. This means that it can withstand high-temperature operations and harsh chemical environments without compromising its performance or integrity. As a result, manufacturers can rely on the YG15X blank to deliver exceptional results across a wide range of applications, from precision machining to heavy-duty metalworking.Furthermore, {} (company name) is dedicated to providing customized solutions to meet the specific needs of its customers. The company's team of experienced engineers and technicians work closely with clients to develop tailored carbide solutions that address their unique challenges and requirements. Whether it's designing custom tooling or optimizing machining processes, {} is committed to delivering innovative solutions that drive success for its customers.With a focus on quality, performance, and customer satisfaction, {} has earned the trust and loyalty of clients across various industries. The company's relentless pursuit of excellence has positioned it as a preferred supplier of tungsten carbide blanks and related products. By consistently delivering superior products and exceptional service, {} continues to set the standard for excellence in the carbide industry.In conclusion, the YG15X tungsten carbide blank from {} represents the latest advancement in high-performance carbide solutions. With its exceptional hardness, toughness, and resistance to heat and corrosion, this premium-grade material is well-suited for a wide range of industrial applications. Backed by {}'s commitment to quality and innovation, the YG15X blank stands as a testament to the company's dedication to providing reliable and high-performance carbide solutions. As the demand for superior tungsten carbide blanks continues to rise, {} is well-positioned to meet the needs of manufacturers seeking a trusted and reputable supplier.

Discover the Latest Hot Rolling News and Trends

Hot Rolling Technology Continues to Lead the Way in Steel ManufacturingIn the heart of the steel manufacturing industry, advancements in hot rolling technology have continued to revolutionize the way steel is produced. With the introduction of cutting-edge equipment and the implementation of innovative processes, the industry has seen remarkable improvements in efficiency, quality, and sustainability.Hot rolling is a crucial step in the production of steel, as it involves heating the metal to high temperatures and then passing it through a series of rollers to shape it into the desired form. This process requires a precise combination of temperature control, pressure, and speed, all of which have a significant impact on the final product.One company at the forefront of hot rolling technology is {}. Leveraging decades of experience in the steel industry, {} has been at the forefront of developing and implementing state-of-the-art hot rolling equipment and processes.With a commitment to innovation, {} has continuously invested in research and development to push the boundaries of what is possible in hot rolling technology. This dedication has paid off, as {} has been able to develop a range of advanced solutions that have set new standards in the industry.One of the key innovations introduced by {} is the use of advanced automation and control systems in hot rolling mills. By integrating cutting-edge technology, {} has been able to achieve unprecedented levels of precision and consistency in the hot rolling process, resulting in significant improvements in product quality and yield.In addition to automation, {} has also focused on enhancing the sustainability of hot rolling operations. By optimizing energy usage and implementing efficient waste management practices, {} has been able to reduce the environmental impact of its manufacturing processes while maintaining high levels of productivity.Furthermore, {} has not only focused on improving the hardware of hot rolling mills but has also placed a strong emphasis on enhancing the software and data analytics capabilities. By leveraging big data and advanced analytics, {} has been able to gain valuable insights into the hot rolling process, leading to further improvements in efficiency and product quality.The impact of {}'s advancements in hot rolling technology has been felt across the steel industry, as manufacturers have been able to produce higher-quality steel products in a more cost-effective and sustainable manner. As a result, {}'s hot rolling solutions have become widely sought after by steel producers around the world.Looking ahead, {} remains committed to pushing the boundaries of hot rolling technology even further. With ongoing investment in research and development, {} is continuously exploring new opportunities to optimize the hot rolling process and set new benchmarks for the industry.In conclusion, hot rolling technology has been a key driver of innovation and progress in the steel manufacturing industry, and {} has emerged as a leading force in this area. With its relentless focus on innovation, quality, and sustainability, {} has continued to set new standards for hot rolling technology, shaping the future of steel production.

Tungsten Carbide Manufacturing: Key Insights into this High-Performance Material

Tungsten Carbide Manufacture Announces Expansion PlansTungsten Carbide Manufacture, a leading company in the manufacturing of industrial-grade tungsten carbide products, announced today its plans for expansion in order to meet the growing market demand. The company has established itself as a key player in the industry and aims to further cement its position with this strategic move.Since its establishment in 2005, Tungsten Carbide Manufacture has been dedicated to providing high-quality, innovative tungsten carbide products to a diverse range of industries including mining, construction, automotive, and aerospace. With a strong focus on research and development, the company has consistently introduced cutting-edge solutions that have exceeded customer expectations.As Tungsten Carbide Manufacture continues to experience steady growth, it has recognized the need to expand its production capacity to keep up with the rising demand for its products. The company plans to invest in state-of-the-art machinery and technology to enhance its manufacturing capabilities and streamline its processes.The expansion will also entail the construction of a new manufacturing facility, which will not only increase production capacity but also allow for the introduction of new product lines. Tungsten Carbide Manufacture aims to expand its product offerings to cater to a wider range of customer needs and diversify its revenue streams.In addition to the physical expansion, Tungsten Carbide Manufacture plans to invest in the development of its workforce. The company believes that its employees are its greatest asset and recognizes the importance of investing in their knowledge and skills. To that end, it will be implementing training programs and workshops to enhance the technical proficiency and expertise of its workforce.Tungsten Carbide Manufacture's commitment to sustainability will also be at the forefront of its expansion plans. The company recognizes the importance of responsible manufacturing practices and plans to integrate eco-friendly technologies in its new facility. By minimizing energy consumption and reducing waste, Tungsten Carbide Manufacture aims to lessen its environmental impact and contribute to a cleaner, greener future.With this expansion, Tungsten Carbide Manufacture aims to consolidate its position as a leading manufacturer and supplier of tungsten carbide products. The company's dedication to quality, innovation, and sustainability has garnered it a loyal customer base, with clients ranging from small businesses to multinational corporations.Notably, Tungsten Carbide Manufacture stands out in the industry for its exceptional customer service. The company prides itself on its ability to provide customized solutions to meet the unique requirements of its clients. By expanding its production capacity and diversifying its product offerings, Tungsten Carbide Manufacture will be better equipped to serve its customers and exceed their expectations.The expansion plans of Tungsten Carbide Manufacture come at a time when the demand for high-performance tungsten carbide products is on the rise across various industries. With its commitment to quality, innovation, and sustainability, the company is poised to meet this demand and solidify its position in the market.In conclusion, Tungsten Carbide Manufacture's announcement of its expansion plans highlights its commitment to growth and customer satisfaction. With the construction of a new manufacturing facility and investment in cutting-edge technology, the company will be able to increase its production capacity and introduce new product lines. By prioritizing employee development and adopting eco-friendly practices, Tungsten Carbide Manufacture aims to strengthen its position as a leading player in the industry.

Carbide Molds: The Latest Advancements in Mold Manufacturing

Carbide Molds: The Pinnacle of Precision and QualityCarbide molds have long been considered the industry standard for precision and quality in the manufacturing and production of a wide range of products. These molds are made from a combination of tungsten and carbon, resulting in a material that is extremely durable, resistant to wear and tear, and capable of maintaining its shape and precision even under the most demanding conditions. With these exceptional qualities, it's no wonder that carbide molds have become an indispensable tool for companies across a range of industries.One company that has established itself as a leader in the production of carbide molds is {}. With over 20 years of experience in the industry, {} has consistently delivered top-notch carbide molds that meet the high standards of precision and quality demanded by their clients. The company's commitment to excellence and innovation has earned them a reputation as a trusted partner for businesses seeking the highest quality molds for their production needs.One of the key advantages of carbide molds is their exceptional hardness. This hardness allows them to withstand the pressures and forces exerted during the manufacturing process, ensuring that the finished products meet the required specifications and standards. Additionally, the durability of carbide molds means that they have a longer lifespan than traditional steel molds, reducing the need for frequent replacements and minimizing downtime in production. This leads to significant cost savings for companies using carbide molds in their manufacturing processes.Another important benefit of carbide molds is their ability to maintain their precision over time. Unlike other materials, carbide does not easily warp, deform, or degrade, even under extreme temperatures and pressures. This means that products manufactured using carbide molds consistently meet the required specifications, leading to higher customer satisfaction and fewer rejected parts. This precision is particularly important in industries such as aerospace, medical device manufacturing, and automotive, where even the slightest deviation from the required specifications can have serious consequences.In addition to their exceptional durability and precision, carbide molds are also highly resistant to wear and corrosion. This makes them ideal for use in the production of a wide range of products, including plastic components, metal parts, and other industrial components. Regardless of the material being molded, carbide molds offer the assurance of consistent quality and performance, making them an essential tool for manufacturers seeking to maintain a competitive edge in their respective industries.{} stands out in the industry for its ability to customize carbide molds to meet the specific needs of its clients. The company's team of highly skilled engineers and technicians work closely with customers to understand their unique requirements and develop customized carbide molds that are tailored to their precise specifications. This level of customization ensures that customers receive molds that are perfectly suited to their production processes, leading to improved efficiency, reduced waste, and higher overall product quality.Moreover, {} consistently invests in the latest technologies and manufacturing processes to ensure that their carbide molds are at the forefront of innovation and quality. The company's state-of-the-art facilities enable them to produce molds with unmatched precision and consistency, guaranteeing that their customers receive the highest quality products every time.In conclusion, carbide molds have become a cornerstone of modern manufacturing processes, offering unmatched durability, precision, and quality to businesses across a range of industries. As a leading producer of carbide molds, {} has positioned itself as a trusted partner for companies seeking exceptional quality and performance in their production processes. With a commitment to excellence and innovation, {} continues to set the standard for carbide molds, ensuring that their customers can rely on the highest level of precision and quality in their manufacturing operations.

Durable Tungsten Carbide Cutting Tools for Precision Machining

Tungsten Carbide Cutting Tools are an essential component in the manufacturing and machining industry. Known for their incredible hardness and durability, these cutting tools are widely used for cutting, drilling, grinding, and shaping various materials such as metal, wood, plastic, and composites.One of the leading manufacturers of Tungsten Carbide Cutting Tools is {}. With a strong focus on innovation and quality, {} has been supplying cutting-edge cutting tools to a wide range of industries including automotive, aerospace, oil and gas, and general engineering. The company's extensive range of cutting tools includes end mills, drills, reamers, and inserts, all of which are designed to deliver exceptional performance and efficiency.Tungsten carbide is a composite material made up of tungsten and carbon atoms, resulting in a material that is incredibly hard and wear-resistant. This makes it an ideal choice for cutting tools, as it can withstand the high temperatures and pressures involved in cutting and shaping tough materials. When combined with the expertise and precision engineering of {}, the result is a range of cutting tools that are renowned for their superior performance and long lifespan.In addition to their exceptional hardness, Tungsten Carbide Cutting Tools from {} are also known for their high thermal conductivity and low coefficient of friction. This means that the tools can operate at higher cutting speeds and temperatures without losing their cutting edge, resulting in faster and more efficient machining processes. This is particularly important in industries such as aerospace and automotive, where precision and speed are of the utmost importance.One of the key advantages of {}'s Tungsten Carbide Cutting Tools is their versatility. The company offers a wide range of cutting tools with various geometries, coatings, and cutting edge designs, allowing customers to select the most suitable tool for their specific machining requirements. Whether it's high-speed machining, heavy-duty roughing, or high-precision finishing, {} has a cutting tool that can meet the demands of any application.Another factor that sets {} apart from other cutting tool manufacturers is their commitment to innovation and continuous improvement. The company invests heavily in research and development to constantly improve the performance and durability of their cutting tools. This includes refining the materials and manufacturing processes used to produce the tools, as well as developing new and more efficient tool designs.{}'s dedication to quality is evident in their state-of-the-art manufacturing facilities, which are equipped with the latest machinery and technology for producing cutting-edge cutting tools. The company also has a team of highly skilled engineers and technicians who are continuously testing and refining their products to ensure that they meet the highest standards of quality and performance.In conclusion, Tungsten Carbide Cutting Tools from {} are a testament to the company's commitment to excellence and innovation. With their exceptional hardness, durability, and versatility, these cutting tools are the go-to choice for a wide range of industries that require high-performance machining solutions. With a focus on quality and continuous improvement, {} continues to be a leader in the cutting tool industry, providing its customers with the tools they need to stay ahead of the competition.

High-Quality Carbide Wear Parts for Industrial Applications

Carbide Wear Parts has been making waves in the manufacturing industry with their innovative and high-quality products. The company has been a leading supplier of wear parts for a wide range of industries, such as mining, construction, and oil and gas. With a strong focus on research and development, Carbide Wear Parts has been able to consistently deliver cutting-edge solutions to its customers.Founded in 2005, Carbide Wear Parts quickly established itself as a reliable and reputable source for wear parts. The company's commitment to excellence and dedication to customer satisfaction has allowed it to build a strong reputation in the industry. As a result, Carbide Wear Parts has become a preferred supplier for many leading manufacturers and companies around the world.One of the key factors that sets Carbide Wear Parts apart from its competitors is its use of advanced materials and manufacturing techniques. The company leverages the latest advancements in carbide technology to produce wear parts that offer superior performance and durability. This has made Carbide Wear Parts a trusted partner for companies looking for reliable solutions to their wear part needs.Carbide Wear Parts prides itself on its ability to provide custom solutions to its customers. The company understands that each industry and application has unique requirements, and it is committed to working closely with its clients to develop tailored solutions that meet their specific needs. This personalized approach has helped Carbide Wear Parts build strong relationships with its customers, and has contributed to its continued growth and success.In addition to its focus on quality and customer satisfaction, Carbide Wear Parts is also dedicated to sustainability and environmental responsibility. The company is committed to minimizing its environmental impact and has implemented a number of initiatives to reduce waste and pollution in its manufacturing process. By prioritizing sustainability, Carbide Wear Parts is able to provide its customers with environmentally friendly products that meet their performance requirements.The success of Carbide Wear Parts can be attributed to its talented team of engineers and industry experts. The company has assembled a team of highly skilled professionals who are passionate about delivering innovative solutions to their customers. With their expertise and dedication, Carbide Wear Parts has been able to stay ahead of the competition and continue to push the boundaries of what is possible in the wear parts industry.Looking to the future, Carbide Wear Parts is poised for continued growth and success. The company is constantly looking for new ways to innovate and improve its products, and is committed to staying at the forefront of wear part technology. With its strong foundation of quality, innovation, and customer satisfaction, Carbide Wear Parts is well positioned to remain a leader in the industry for years to come.In conclusion, Carbide Wear Parts has established itself as a trusted and reliable supplier of wear parts for a wide range of industries. Through its focus on quality, innovation, and customer satisfaction, the company has been able to build strong relationships with its customers and maintain a leading position in the industry. With its commitment to sustainability and ongoing dedication to excellence, Carbide Wear Parts is well positioned for continued success in the years to come.

High-Quality Tungsten Carbide Manufacturing: Everything You Need to Know

Tungsten carbide is a versatile material that is used in a wide range of industries, from aerospace to mining to manufacturing. It is known for its hardness, strength, and resistance to wear and corrosion, making it an ideal material for a variety of applications. One company that has been at the forefront of tungsten carbide manufacture is {}. With a long history of innovation and expertise in the industry, they have established themselves as a leading supplier of high-quality tungsten carbide products.Founded in {}, {} has over {} years of experience in the manufacture of tungsten carbide. Their state-of-the-art facilities and advanced technology allow them to produce a wide range of tungsten carbide products, including cutting tools, wear parts, and components for a variety of industrial applications. They are committed to quality and precision, and their products are known for their reliability and long-lasting performance.One of the key factors that sets {} apart from other companies in the industry is their emphasis on research and development. They have a team of dedicated scientists and engineers who are constantly working to improve their processes and develop new and innovative tungsten carbide products. This commitment to innovation has allowed them to stay ahead of the competition and meet the evolving needs of their customers.In addition to their focus on research and development, {} is also committed to sustainability and environmental responsibility. They have implemented rigorous environmental standards in their manufacturing processes and are constantly seeking ways to reduce their environmental impact. This commitment to sustainability has not only earned them the trust and respect of their customers, but has also positioned them as a leader in the industry.Furthermore, {} has a strong emphasis on customer service and satisfaction. They work closely with their customers to understand their specific needs and provide customized solutions to meet those needs. Whether it's developing a unique tungsten carbide product or providing technical support and expertise, {} is dedicated to ensuring that their customers receive the highest level of service and support.With a focus on quality, innovation, sustainability, and customer service, {} has earned a reputation as a trusted and reliable supplier of tungsten carbide products. Their dedication to excellence has made them a preferred partner for companies across a wide range of industries, and their products are used in some of the most demanding and high-performance applications.Looking to the future, {} is poised to continue leading the way in tungsten carbide manufacture. With their ongoing commitment to research and development, sustainability, and customer service, they are well-positioned to meet the evolving needs of the industry and continue providing high-quality tungsten carbide products for years to come. As the demand for advanced materials continues to grow, companies like {} will play a crucial role in driving innovation and shaping the future of the industry.

Top-Notch Tungsten Carbide Roll Rings: A Game-Changer in Industrial Applications

Tungsten Carbide Roll Rings Maximize Performance and Productivity in Steel MillsSteel mills are highly competitive and demanding environments that require the highest standards of performance and efficiency. One of the key components that determine the success of a steel mill is the quality of its rolls, which are essential for achieving precise, consistent, and reliable results. This is where tungsten carbide roll rings come into play, providing a superior solution for maximizing performance and productivity in steel rolling processes.Tungsten carbide roll rings are made of a highly durable and wear-resistant material that can withstand extreme temperatures, pressures, and stresses. They are designed to deliver exceptional strength, hardness, and toughness, making them ideal for use in demanding applications that require high precision and accuracy. These benefits are especially important for steel mills, which rely heavily on rolls to shape and refine their products.At the same time, tungsten carbide roll rings offer a number of advantages over other materials used in roll manufacturing. For example, they provide superior resistance to wear, corrosion, and deformation, which can prolong the lifespan of the rolls and reduce maintenance and replacement costs. They also offer high levels of accuracy, repeatability, and consistency, which are essential for ensuring product quality and consistency.In addition, tungsten carbide roll rings are highly versatile and can be customized to meet the specific needs of different steel rolling processes. They can be designed in various shapes, sizes, and configurations, depending on the type of steel being processed, the rolling speeds and forces involved, and other factors. This flexibility allows steel mills to optimize their operations and achieve the best results possible.To meet these demands, the leading manufacturer of tungsten carbide roll rings has developed innovative solutions that combine advanced materials, engineering, and manufacturing expertise. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable supplier of roll rings to steel mills around the world.The company's tungsten carbide roll rings are produced using a sophisticated process that ensures consistent quality and performance. The rolls are made of high-purity tungsten carbide powders, which are blended with other materials to achieve the desired properties. The mixture is then compacted under high pressure, sintered at high temperatures, and machined to the required dimensions. The result is a high-quality roll ring that meets the most demanding specifications.To guarantee the performance and durability of its roll rings, the company uses advanced testing and inspection methods. These include hardness testing, microstructure analysis, dimensional measurement, and visual inspection. The rigorous quality control procedures ensure that each roll ring meets the highest standards of quality and reliability.Moreover, the company provides comprehensive support services to its customers, including on-site installation, training, and maintenance. This ensures that steel mills can maximize the benefits of tungsten carbide roll rings and achieve the best results possible. With its commitment to innovation, quality, and customer satisfaction, the company has become a preferred supplier of roll rings to steel mills worldwide.In conclusion, tungsten carbide roll rings have become a critical component in the steel industry, providing exceptional performance, durability, and versatility. With the support of a leading supplier of tungsten carbide roll rings, steel mills can optimize their operations and achieve the highest levels of productivity and efficiency. As the steel industry continues to evolve, tungsten carbide roll rings will play an increasingly important role in shaping its future.