Durable Tungsten Carbide Ring - HR15Y

By:Admin

[City, Date]: [Company Name] is proud to announce the launch of its latest product, the HR15Y Tungsten Carbide Ring. This new addition to the [Company Name] product line is designed to be a durable and stylish accessory for people of all ages and backgrounds.

Tungsten carbide is a material known for its strength and durability, making it an ideal choice for jewelry that is meant to last a lifetime. The HR15Y Tungsten Carbide Ring is no exception, as it is made with the highest quality tungsten carbide to ensure its longevity and resistance to scratches and wear. This makes it the perfect choice for individuals with active lifestyles who need a ring that can keep up with their activities.

In addition to its durability, the HR15Y Tungsten Carbide Ring is also designed to be stylish and versatile. It features a sleek and modern design that can be dressed up or down, making it a great choice for any occasion. Whether it's a casual day out or a formal event, this ring is sure to make a statement and add a touch of sophistication to any outfit.

One of the key features that sets the HR15Y Tungsten Carbide Ring apart from other jewelry options is its affordable price point. While many other durable and high-quality jewelry pieces come with a hefty price tag, [Company Name] is committed to providing customers with access to top-notch products at a reasonable cost. The HR15Y Tungsten Carbide Ring is a testament to this commitment, offering exceptional quality at an affordable price.

As a company, [Company Name] is dedicated to providing its customers with the best products and experience possible. This dedication is reflected in the HR15Y Tungsten Carbide Ring, as it has been meticulously designed and crafted to meet the highest standards of quality and style. With this new addition to its product line, [Company Name] continues to demonstrate its commitment to excellence and customer satisfaction.

In addition to its new product launch, [Company Name] is also excited to announce that the HR15Y Tungsten Carbide Ring is now available for purchase on its website and at select retailers. Customers can now experience the durability, style, and affordability of this ring for themselves by visiting the [Company Name] website or reaching out to their nearest retailer.

To learn more about the HR15Y Tungsten Carbide Ring and [Company Name]'s other products, customers are encouraged to visit the company's website or contact its customer service team for assistance.

With the introduction of the HR15Y Tungsten Carbide Ring, [Company Name] continues to elevate its product line and provide customers with durable and stylish jewelry options at an affordable price. This new addition is a reflection of the company's commitment to quality, style, and customer satisfaction.

Company News & Blog

High-Quality Tungsten Carbide Plate Bar Sheet Blank for Industrial Applications

Tungsten Carbide Plate Bar Sheet Blank is a high-performance material that is widely used in various industries for its excellent hardness, wear resistance, and strength. As a leading supplier of Tungsten Carbide Plate Bar Sheet Blank, [Company Name] is dedicated to providing high-quality products and reliable services to its customers around the world.With a strong focus on innovation and quality, [Company Name] has built a reputation for delivering top-notch Tungsten Carbide Plate Bar Sheet Blank that meets the highest standards of performance and durability. The company's Tungsten Carbide Plate Bar Sheet Blank is manufactured using advanced technology and high-quality raw materials, ensuring superior quality and consistency.[Company Name] offers a wide range of Tungsten Carbide Plate Bar Sheet Blank products in various sizes and dimensions to meet the diverse needs of its customers. Whether it's for cutting, drilling, mining, or any other industrial application, the company's Tungsten Carbide Plate Bar Sheet Blank is designed to deliver exceptional performance and longevity.In addition to its high-quality products, [Company Name] is also committed to providing excellent customer service and support. The company's team of experienced professionals is dedicated to understanding the specific requirements of each customer and delivering tailored solutions to meet their needs.[Company Name]'s Tungsten Carbide Plate Bar Sheet Blank is widely used in a range of industries, including metalworking, woodworking, mining, construction, and oil and gas. The company's products are known for their exceptional hardness, wear resistance, and performance in challenging working environments.One of the key advantages of [Company Name]'s Tungsten Carbide Plate Bar Sheet Blank is its long service life, which helps to reduce downtime and maintenance costs for its customers. This makes the company's products a cost-effective choice for businesses looking to improve their productivity and efficiency.As a global leader in Tungsten Carbide Plate Bar Sheet Blank, [Company Name] is constantly investing in research and development to enhance its product range and stay ahead of the competition. The company's commitment to innovation and quality has earned it the trust and loyalty of customers from all over the world.In summary, [Company Name] is a trusted supplier of high-quality Tungsten Carbide Plate Bar Sheet Blank, offering a wide range of products to meet the diverse needs of its customers. With a focus on innovation, quality, and customer service, the company is well-positioned to continue its leadership in the global market for Tungsten Carbide Plate Bar Sheet Blank. For businesses looking for reliable and high-performance Tungsten Carbide Plate Bar Sheet Blank, [Company Name] is the ultimate choice.

Discover the Benefits of Tungsten Carbide Studs in Various Applications

Title: Innovations in Tungsten Carbide Stud Technology Revolutionize Industrial ApplicationsIntroduction:Tungsten Carbide Stud, a pioneering material in the realm of industrial applications, is set to redefine the standards of durability and performance in a wide range of sectors. With its exceptional hardness, heat resistance, and overall versatility, Tungsten Carbide Stud has garnered significant attention from various industries looking to enhance their products and processes. As one of the leading manufacturers in this field, our company strives to push the boundaries of this technology by continuously innovating and improving our products, ensuring optimum efficiency and longevity in demanding environments.Body:1. Understanding Tungsten Carbide Stud and its Properties:Tungsten Carbide Stud, also known as cemented carbide or simply carbide, is a composite material comprising tungsten carbide grains mixed with a binder alloy, typically cobalt. This combination results in a material that exhibits exceptional hardness, strength, and overall wear resistance, surpassing those of traditional materials such as steel. Its outstanding thermal conductivity and resistance to extreme temperatures make it invaluable in heavy-duty applications, including mining, drilling, construction, and machining.2. Enhanced Performance: The incorporation of Tungsten Carbide Stud components in industrial tools and equipment has revolutionized their performance, enabling them to withstand high-stress operations for prolonged durations. Cutting tools, such as drill bits, saw blades, and milling cutters, equipped with Tungsten Carbide Stud inserts, exhibit superior cutting speeds, increased tool life, and excellent chip control. This enhanced performance leads to reduced downtime, increased productivity, and ultimately, cost savings for businesses.3. Mining and Drilling Applications:In the mining and drilling sector, Tungsten Carbide Stud components are crucial in ensuring optimal performance and safety. Due to their exceptional hardness and resistance to abrasion, Tungsten Carbide Stud inserts and tips are commonly used in rock drilling bits, thus improving the efficiency and longevity of drilling operations. Moreover, their ability to withstand extreme pressure and temperature variations makes them ideal for use in downhole drilling tools, where reliability is paramount.4. Construction and Infrastructure:Tungsten Carbide Stud's exceptional wear resistance and toughness lend themselves to applications within the construction and infrastructure industries. With their incorporation into wear parts like cutting edges, bucket teeth, and crushers, these components offer extended service life and reduced maintenance costs. Furthermore, Tungsten Carbide Stud is utilized in tool attachments such as road milling teeth and foundation drilling bits, enabling efficient road construction and deep foundation drilling.5. Machining and Manufacturing:The exceptional hardness of Tungsten Carbide Stud has significant implications for machining and manufacturing processes. Utilizing these materials in metal-cutting inserts, die components, and wear-resistant coatings substantially improves tool life, reduces the need for frequent tool changes, and enhances overall manufacturing efficiency. Additionally, Tungsten Carbide Stud finds applications in metal-forming processes, where its high hardness and compressive strength aid in wire drawing dies, cold heading dies, and extrusion tools.6. Ongoing Innovations:As a leader in the Tungsten Carbide Stud industry, our company remains committed to continuous research and development, harnessing the capabilities of this remarkable material to develop customized solutions that cater to our clients' specific needs. We collaborate closely with industry partners and customers to develop novel applications, improve manufacturing processes, and enhance the durability and efficiency of our products. Our dedication to innovation positions us at the forefront of the industry, enabling us to deliver cutting-edge solutions and establish long-term partnerships.Conclusion:Through the remarkable properties offered by Tungsten Carbide Stud, industries can enhance their performance, reduce costs, and optimize their operations. With its exceptional hardness, heat resistance, and versatility, this composite material has become indispensable in various applications across multiple sectors. As an industry-leading manufacturer, we pride ourselves on continuously pushing the boundaries of Tungsten Carbide Stud technology. By constantly innovating and refining our products, we strive to meet the evolving demands of our clients and contribute to the advancement of global industries.

Top 10 Benefits of Using a Content Mill Roller for Your Business

[Company Name] Unveils New State-of-the-Art Mill Roller Technology[City, Date] - [Company Name], a global leader in the manufacturing of industrial equipment, has recently launched its latest innovation in mill roller technology. The new state-of-the-art mill roller is set to revolutionize the milling industry by offering improved efficiency, performance, and productivity.With over [number] years of experience in the industry, [Company Name] has built a reputation for delivering cutting-edge solutions that meet the evolving needs of its customers. The company's commitment to innovation and excellence is evident in the development of its new mill roller technology.The new mill roller is designed to enhance the milling process by providing a more consistent and efficient grinding performance. Its advanced design features ensure that the mill roller can handle a wide range of materials with precision and accuracy, resulting in higher quality output and reduced maintenance requirements.In addition to its superior performance, the new mill roller also offers enhanced durability and longevity. The use of high-quality materials and precision engineering ensures that the mill roller can withstand the rigors of heavy-duty milling operations, reducing downtime and maintenance costs for customers.Furthermore, the new mill roller incorporates advanced technology to optimize energy efficiency and minimize environmental impact. By reducing energy consumption and emissions, [Company Name] is helping its customers operate more sustainably and responsibly, aligning with the growing trend towards environmentally-friendly manufacturing practices."We are thrilled to introduce our latest innovation in mill roller technology," said [Company Name]'s CEO. "Our new mill roller is the result of extensive research, development, and testing, and we are confident that it will deliver significant benefits to our customers. This is a testament to our ongoing commitment to excellence and our dedication to driving innovation in the industry."The new mill roller technology is now available for customers globally, and [Company Name] has already received positive feedback from early adopters. The company is also offering comprehensive support and after-sales service to ensure that customers can maximize the benefits of the new technology.In addition to its latest mill roller, [Company Name] offers a comprehensive range of industrial equipment, including crushers, screens, and conveyors, serving various industries such as mining, construction, and aggregate processing. The company's products are renowned for their quality, reliability, and performance, and are trusted by customers around the world.[Company Name] is also committed to ongoing research and development to continue pushing the boundaries of innovation in industrial equipment. The company's dedicated team of engineers and technical experts are constantly exploring new technologies and solutions to address the evolving needs of its customers and the industry as a whole.As the industry continues to evolve, [Company Name] remains at the forefront of innovation, delivering advanced solutions that empower its customers to achieve new levels of productivity, efficiency, and sustainability. With its latest mill roller technology, the company is set to further solidify its position as a leading provider of industrial equipment and a trusted partner for businesses worldwide.For more information about [Company Name] and its latest mill roller technology, please visit [company website].

High-quality Carbide Nail Making Die for Long-lasting Nail Manufacturing

Carbide Nail Making Die Revolutionizes Nail ProductionThe nail-making industry has long relied on traditional steel dies for the production of nails. But now, (remove brand name) is revolutionizing the industry with the introduction of their carbide nail making die. This innovative product is set to transform nail production by offering unparalleled durability, efficiency, and precision.Established in {year}, (remove brand name) has been a leading provider of cutting-edge tools and equipment for the manufacturing industry. With a strong emphasis on research and development, the company has continuously pushed the boundaries of innovation to meet the evolving needs of their clients. Through their commitment to excellence, (remove brand name) has earned a reputation for delivering high-quality products that enhance productivity and performance.The carbide nail making die is the latest addition to (remove brand name)'s product line, and it promises to revolutionize the way nails are produced. Made from premium-grade carbide, this die offers exceptional hardness and wear resistance, ensuring a long lifespan and minimal maintenance. This means that manufacturers can expect consistent and reliable performance, leading to fewer interruptions and downtimes in their production processes.In addition to its superior durability, the carbide nail making die also delivers unmatched precision and accuracy. The ultra-hard carbide material allows for the creation of nail heads with smooth and uniform surfaces, reducing the need for post-production finishing processes. This not only saves time and resources but also ensures that the nails meet the highest quality standards, ultimately enhancing the overall product value.Furthermore, the carbide nail making die is designed for optimal efficiency, enabling manufacturers to increase their production rates while maintaining consistent nail quality. With its high resistance to wear and deformation, the die can operate at higher speeds and pressures, resulting in greater output without compromising on precision and reliability. This is a significant advantage for nail manufacturers looking to meet growing market demands without sacrificing product integrity.The introduction of the carbide nail making die underscores (remove brand name)'s commitment to driving innovation and advancing the manufacturing industry. By leveraging their expertise in materials science and engineering, the company has developed a game-changing solution that addresses the limitations of traditional steel dies and sets a new standard for nail production. With this innovative product, (remove brand name) continues to cement its position as a trailblazer in the field of industrial tools and equipment.The release of the carbide nail making die has already garnered widespread attention within the manufacturing community, with industry professionals expressing keen interest in its potential impact. Many are eager to witness firsthand the benefits of this cutting-edge technology and explore how it can improve their own nail production processes. (remove brand name) is poised to capitalize on this anticipation, positioning itself as a key player in the ongoing transformation of the nail-making industry.Looking ahead, (remove brand name) remains dedicated to pushing the boundaries of innovation and pushing the nail-making industry forward. The company's relentless pursuit of excellence and its unwavering commitment to meeting the evolving needs of manufacturers ensure that it will continue to deliver groundbreaking solutions that redefine industry standards. As the carbide nail making die takes center stage, (remove brand name) is poised to make a lasting impact on the manufacturing landscape.

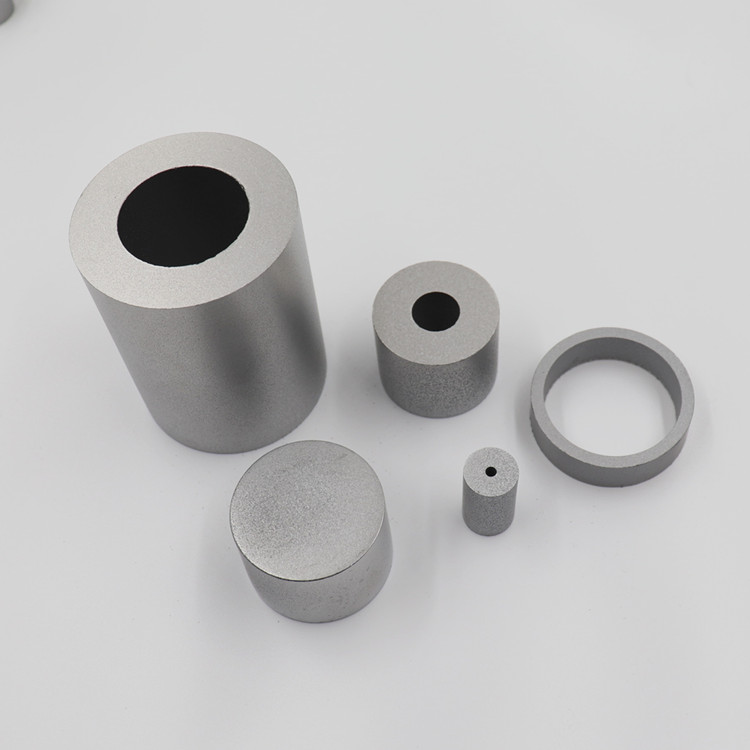

Durable Tungsten Carbide Sleeves for Wear-Resistant Applications

Wear-Resistant Tungsten Carbide Sleeves have become an essential component in various industries, including oil and gas, mining, automotive, and aerospace. These sleeves are known for their exceptional strength, durability, and resistance to wear, making them a popular choice for applications where extreme conditions are a common occurrence.One company that specializes in the production of these high-quality tungsten carbide sleeves is {}. With a strong focus on innovation and technology, {} has established itself as a leading manufacturer of wear-resistant components for a wide range of industries.The company's extensive experience in the field of tungsten carbide manufacturing dates back to over a decade. During this time, {} has continuously invested in research and development, allowing them to create advanced solutions that meet the ever-evolving needs of their customers. The company's commitment to quality and excellence has earned them a solid reputation as a trusted provider of wear-resistant products.The wear-resistant tungsten carbide sleeves produced by {} are designed to withstand the harshest operating conditions. Whether it's high-temperature environments, abrasive substances, or heavy mechanical loads, these sleeves are engineered to deliver exceptional performance and longevity. This makes them an ideal choice for critical applications where equipment reliability is paramount.In addition to their superior wear resistance, {}'s tungsten carbide sleeves are also known for their precise dimensions and tight tolerances. This ensures a perfect fit and reliable operation, ultimately contributing to the overall efficiency and productivity of the equipment they are used in. Furthermore, the company offers custom machining services, allowing them to produce sleeves that are tailored to meet the specific requirements of their customers.With a strong focus on customer satisfaction, {} takes pride in providing prompt and personalized service to their clients. The company's team of technical experts is readily available to offer advice and support, ensuring that the right solutions are delivered to meet each customer's unique needs.Aside from their commitment to quality and customer service, {} is also dedicated to environmental sustainability and ethical business practices. The company adheres to strict environmental standards in their manufacturing processes, aiming to minimize their carbon footprint and reduce waste. Furthermore, {} is committed to ensuring fair and safe working conditions for their employees, as well as maintaining a positive impact on the communities in which they operate.Looking ahead, {} remains focused on driving innovation and delivering excellence in the field of wear-resistant tungsten carbide components. As industries continue to evolve and demand higher performance from their equipment, companies like {} play a crucial role in providing the advanced solutions needed to meet these challenges.In conclusion, the demand for wear-resistant tungsten carbide sleeves continues to grow across various industries, and companies like {} are at the forefront of meeting this demand. With their dedication to quality, innovation, and customer satisfaction, {} has established itself as a trusted provider of high-performance wear-resistant products. As the industry evolves, {} remains committed to delivering cutting-edge solutions that help their customers thrive in today's competitive market.

The Advantages of Using Tungsten Carbide Material for various Applications

Title: Tungsten Carbide Material Revolutionizes Industries with Unparalleled Durability and VersatilityIntroduction:In today's ever-evolving industrial landscape, material innovation plays a crucial role in driving progress and shaping the future. Among the various groundbreaking materials being developed, Tungsten Carbide stands out as a true champion. Renowned for its unrivaled durability, versatility, and exceptional performance, Tungsten Carbide offers a multitude of opportunities across a wide range of industries. This revolutionary material is changing the way we approach manufacturing, engineering, and beyond.Unleashing the Potential: Tungsten Carbide MaterialTungsten Carbide has emerged as a game-changer in the world of material science. Prominent for its superior hardness, tensile strength, and resistance to wear and corrosion, this metallic compound has proved to be a standout performer in numerous sectors.1. Manufacturing Reinvented:The manufacturing industry, known for its relentless pursuit of efficiency and excellence, has found a perfect partner in Tungsten Carbide. With a hardness comparable to that of diamond, this material has become a go-to choice for tools and machinery applications. It significantly enhances the lifespan of cutting tools, drills, dies, and molds, making them last longer while withstanding extreme conditions. Manufacturers can now achieve increased productivity, reduced downtime, and improved output quality, resulting in unparalleled cost-effectiveness.2. Revolutionizing Engineering:Tungsten Carbide has revolutionized the engineering landscape by providing engineers with an array of possibilities. From aerospace to automotive applications, its high melting point, low thermal expansion, and exceptional strength are invaluable in the development of high-performance components. The material's remarkable wear resistance allows engineers to create longer-lasting turbine blades, bearings, gears, and various other critical parts. As a result, industries can now produce efficient, safe, and durable equipment, contributing to the advancement of technology and human progress.3. Mining and Extraction Advancements:With the mining and oil industry pushing the boundaries of extraction techniques continually, Tungsten Carbide proves to be an indispensable asset in the quest for better efficiency and productivity. The material's excellent abrasion and erosion resistance make it ideal for drilling bits, compacted tooling, and other underground applications. By implementing Tungsten Carbide into their mining operations, companies can experience enhanced penetration rates, reduced maintenance costs, and improved overall performance, leading to increased profitability and sustainability.4. Beyond Industrial Applications:Tungsten Carbide's versatility extends beyond heavy machinery and industrial components; its ability to withstand extreme conditions and retain superior toughness opens doors for diverse applications. For instance, in the jewelry industry, Tungsten Carbide has gained popularity for its scratch resistance, lustrous appearance, and long-lasting beauty. Similarly, the medical field utilizes this remarkable material in surgical tools, implants, and prosthetic devices, thanks to its biocompatibility and wear resistance. The possibilities seem infinite, as Tungsten Carbide continues to innovate various other niche sectors.Conclusion:As Tungsten Carbide material continues to make waves across industries, its unparalleled durability, versatility, and exceptional performance capture the attention of manufacturers, engineers, and beyond. From manufacturing to mining, this revolutionary material empowers industries to embrace unparalleled cost-effectiveness, efficiency, and productivity. Its remarkable properties enable the creation of tools and components that withstand the harshest environments while maintaining peak performance. As innovation propels us forward, Tungsten Carbide remains at the forefront, reshaping industries and setting new standards for excellence.

Tungsten Carbide Production Skyrockets in China: Discover the Latest Updates and Trends

Title: China's Tungsten Carbide Industry Poised for Steady GrowthIntroduction:China has been a global leader in various industrial sectors, and its thriving tungsten carbide industry is no exception. Tungsten carbide, a versatile and highly valuable material, is used extensively in sectors such as manufacturing, construction, mining, and aerospace due to its exceptional hardness and wear resistance properties. As China continues its progression as an industrial powerhouse, the demand for tungsten carbide products is expected to soar. In this article, we delve into the flourishing tungsten carbide industry in China, its market prospects, and its contribution to the country's economic growth.Overview of Tungsten Carbide China:Tungsten carbide China has emerged as one of the leading suppliers of this crucial material globally. Companies such as [Company name] have established themselves as the key players in the industry, consistently delivering high-quality tungsten carbide products to meet the growing demands of both domestic and international markets.With state-of-the-art manufacturing facilities and advanced research and development capabilities, industry leaders in China have been able to maintain a competitive edge, offering a wide range of tungsten carbide products and solutions tailored to specific customer requirements.Growing Demand and Expanding Markets:The increasing application of tungsten carbide in various industries has been driving the demand for this specialized material. From cutting tools and wear parts to drilling and mining equipment, tungsten carbide plays a pivotal role in enhancing productivity and efficiency across industries.China's rapid urbanization and infrastructure development have fueled the demand for tungsten carbide in construction machinery and tools. As the government continues to invest heavily in transportation infrastructure, including railways and highways, the demand for tougher and wear-resistant tools will increase further.Moreover, the mining sector, which plays a crucial role in China's economy, relies on tungsten carbide for its drilling and cutting operations. The material's strength and durability make it ideal for mining tools, enabling efficient and safe exploration of mineral resources.In addition, the aerospace industry is another significant consumer of tungsten carbide in China. The material's exceptional hardness and capability to withstand high temperatures have made it indispensable in aircraft manufacturing. China's burgeoning aerospace sector is expected to drive the demand for tungsten carbide even higher.Government Support and Technological Advancements:China's government has recognized the importance of the tungsten carbide industry and has provided support to foster its growth. Favorable policies, tax incentives, and investments in research and development have enabled domestic companies to develop innovative products and expand their market reach. Moreover, the establishment of specialized tungsten carbide research institutions has further boosted technological advancements in this field.Environmental Concerns and Sustainable Practices:As the tungsten carbide industry grows, so does the focus on sustainable practices and environmental stewardship. China's leading suppliers have been actively adopting advancements in manufacturing processes to minimize waste, reduce energy consumption, and recycle materials. The industry is dedicated to balancing economic growth with sustainable development, ensuring a greener and more eco-friendly future.Exports and Global Market Expansion:China's tungsten carbide industry has experienced significant growth in exports, catering to the increasing demand from international markets. With its competitive pricing, robust quality control systems, and efficient logistics infrastructure, China has established itself as a reliable supplier of tungsten carbide products worldwide. This expansion into global markets has not only bolstered the country's economy but also enhanced China's reputation as a technologically advanced manufacturer.Conclusion:China's Tungsten Carbide industry, led by companies such as [Company name], is poised for steady growth in the coming years. With increasing demands from various sectors, coupled with government support, technological advancements, and a commitment to sustainable practices, China is set to solidify its position as a global leader in the production and export of tungsten carbide products. As this industry continues to thrive, it will contribute significantly to China's economic growth and reinforce its industry dominance on the global stage.

The Benefits of YG6 YG8 Tungsten Carbide You Need to Know

The demand for high-quality tungsten carbide products has been on the rise in various industries, including mining, construction, and manufacturing. One company that has been meeting this demand with its superior tungsten carbide products is {}.{} is a leading manufacturer and supplier of tungsten carbide products, including YG6 and YG8 grades. These grades of tungsten carbide are known for their exceptional hardness, wear resistance, and strength, making them ideal for a wide range of applications.The YG6 grade of tungsten carbide offered by {} is a fine-grained material that is well-suited for wear parts and cutting tools. It is characterized by its high hardness and excellent wear resistance, making it a popular choice for applications such as drilling and mining.Meanwhile, the YG8 grade of tungsten carbide provided by {} is a medium grain size material that is widely used in applications where high impact resistance is required. This grade is often used in the production of tools and components for construction and metalworking industries.One of the key factors that sets {} apart from its competitors is its commitment to quality. The company uses state-of-the-art manufacturing processes and stringent quality control measures to ensure that its tungsten carbide products meet the highest standards. Additionally, {} has a team of experienced engineers and material experts who work closely with customers to develop customized solutions to meet their specific needs.In addition to its focus on quality, {} is also dedicated to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and develop new grades of tungsten carbide that offer even greater performance and durability.Moreover, {} has a strong commitment to environmental sustainability. The company utilizes advanced technologies and processes to minimize waste and reduce its environmental footprint. It also partners with suppliers who share its commitment to sustainability and ethical business practices.With its comprehensive range of tungsten carbide products, {} serves a diverse customer base that includes manufacturers, construction companies, and mining operations. The company has built a strong reputation for delivering high-quality products and providing exceptional customer service. Its products are widely recognized for their performance, reliability, and long service life.{}’s success is also attributed to its global presence and distribution network. With a strong foothold in international markets, the company is able to reach customers around the world and provide them with the tungsten carbide products they need to drive their business forward.Looking ahead, {} remains committed to pushing the boundaries of tungsten carbide technology and delivering innovative solutions that help its customers achieve their goals. Whether it’s developing new grades of tungsten carbide or expanding its product offerings, the company is continuously striving to stay at the forefront of the industry.In conclusion, {} is a leading provider of high-quality tungsten carbide products, including the YG6 and YG8 grades. With its relentless focus on quality, innovation, and customer satisfaction, the company has earned a reputation as a trusted partner for businesses in a wide range of industries. As the demand for tungsten carbide continues to grow, {} is well-positioned to meet the needs of its customers and drive the industry forward.

The Versatility and Durability of High-Quality Tungsten Carbide Cutter Blades Revealed in Latest News

Tungsten Carbide Cutter Blade: The Heavy-Duty Precision Tool for Industry ApplicationsTungsten Carbide Cutter Blade, the precision tool that has been transforming the industry with its heavy-duty cutting capabilities, is a name that has become synonymous with excellent craftsmanship and reliability. Used in a wide range of industrial applications, Tungsten Carbide Cutter Blade has earned a reputation for being the go-to precision tool for the toughest jobs in construction, manufacturing, and even the metalworking industry.What Makes Tungsten Carbide Cutter Blade Unique?Tungsten Carbide Cutter Blade offers a unique combination of toughness, strength, and durability, which is why it is unmatched in the industry. It is specifically designed to outlast other blades and withstand heavy-duty cutting tasks that would otherwise require multiple blades, which saves time and improves productivity.One of the unique features of the Tungsten Carbide Cutter Blade is its use of tungsten carbide, one of the toughest and densest materials on the planet. When combined with other metals such as cobalt, tungsten carbide forms a compound known as cemenite, which is a very hard and durable material that can withstand high levels of stress. The result is a blade that can cut through almost any material with ease, including wood, metal, and even concrete.Another key feature that sets Tungsten Carbide Cutter Blade apart from other blades on the market is its exceptional edge retention. The blade can maintain a sharp edge for longer periods, which reduces the need for frequent sharpening and replacement, making it more cost-effective in the long run.Applications of Tungsten Carbide Cutter BladeTungsten Carbide Cutter Blade can be used in a wide range of applications, including:1. Construction – Tungsten Carbide Cutter Blade can cut through almost any material used in construction, such as asphalt, concrete, bricks, and stones, making it an essential tool for builders, contractors, and masons.2. Metalworking – Cutting metals such as steel and aluminum requires a blade that can withstand high temperatures and stress. Tungsten Carbide Cutter Blade can handle these conditions, making it a top choice for this industry.3. Manufacturing – Tungsten Carbide Cutter Blade is also used in manufacturing, as it can easily cut through materials like plastics, composites, and fibers, while maintaining its sharp edge for longer periods.Company Introduction and InnovationInnovation is at the heart of Tungsten Carbide Cutter Blade's success. The company has been a leader in the industry for over two decades, producing high-quality precision tools that are designed to make cutting tasks easier and more efficient.Tungsten Carbide Cutter Blade's dedication to innovation is evident in the numerous patents it holds for its cutting-edge products, such as its effective design, advanced manufacturing techniques, and rigorous quality control measures.In addition to cutting-edge research and development, Tungsten Carbide Cutter Blade also invests heavily in its manufacturing processes. The company employs state-of-the-art equipment and processes to ensure the highest quality and precision for each blade. From the initial design stage to the final product, Tungsten Carbide Cutter Blade leaves no stone unturned in its drive for perfection.ConclusionTungsten Carbide Cutter Blade is a precision tool that is unmatched in its toughness, strength, and durability. It is the go-to tool for heavy-duty cutting tasks in a wide range of industrial applications, including construction, metalworking, and manufacturing. Its exceptional edge retention and cutting capabilities make it a cost-effective investment that saves time and improves overall productivity. With Tungsten Carbide Cutter Blade, you can be sure of getting the best in heavy-duty cutting tools, made with an unwavering commitment to quality.

High-Performance Tungsten Carbide Rolls: Unparalleled Strength and Durability

In the world of industrial manufacturing, there is a need for tools and machinery that can withstand the extreme pressure and wear associated with efficient production. One such tool that has gained popularity due to its durability is the tungsten carbide roll, a component used in steel rolling mills. Among the various brands available in the market, the YG8 tungsten carbide roll stands out for its quality and reliable performance.Manufactured by a leading tungsten carbide product supplier, the YG8 tungsten carbide roll is a high-density product that contains a combination of tungsten carbide and cobalt. This unique formulation provides the roll with exceptional hardness and strength, making it ideal for use in high-pressure rolling mills. The YG8 tungsten carbide roll is capable of withstanding severe wear and tear while maintaining precision and accuracy, making it an invaluable tool in the production process.One of the most significant advantages of using the YG8 tungsten carbide roll is that it has a longer lifespan than other types of rolling rolls. This extended lifespan translates into a lower cost of production, as it reduces the need for frequent replacement of the carbide roll. As a result, manufacturing companies can focus on increasing their productivity and revenue while maintaining high quality in their products.In addition to its exceptional quality and durability, the YG8 tungsten carbide roll also offers superior resistance to corrosion and oxidation. This makes it suitable for use in harsh environments, where moisture and chemical exposure can quickly damage other types of rolls. The roll's resistance to corrosion translates into a longer lifespan and an overall reduction in maintenance costs for manufacturing companies.The YG8 tungsten carbide roll is also known for its exceptional performance in high-temperature environments. The roll can withstand temperatures of up to 1000 degrees Celsius, making it ideal for use in hot rolling mills and other areas where high temperatures are prevalent. The roll's ability to handle extreme temperatures ensures that manufacturing companies can produce high-quality products efficiently and without any compromise in quality.Manufacturing companies that use the YG8 tungsten carbide roll can rest assured that they are using a product that has undergone strict quality control measures. The roll is tested and evaluated using advanced techniques to ensure that it meets the required standards for quality and durability. This rigorous testing process ensures that the YG8 tungsten carbide roll is reliable and can deliver consistent performance throughout its lifespan.The YG8 tungsten carbide roll has gained popularity among manufacturing companies in various industries due to its exceptional quality, durability, and performance. The roll's ability to withstand extreme wear and tear, high temperatures, and harsh environments makes it an essential tool in many production lines. With its extended lifespan and superior resistance to corrosion, the YG8 tungsten carbide roll is an excellent investment for manufacturing companies that prioritize efficiency and cost-effectiveness.In conclusion, the YG8 tungsten carbide roll is a reliable and superior quality product that offers exceptional durability and performance. Its unique formulation combining tungsten carbide and cobalt provides the roll with exceptional hardness and strength, making it suitable for use in high-pressure rolling mills. The roll's ability to withstand extreme temperatures, harsh environments, and resistance to corrosion makes it a valuable asset to manufacturing companies. As a tool that has undergone rigorous quality control measures, the YG8 tungsten carbide roll is an excellent investment for companies looking to increase productivity, efficiency, and reduce maintenance costs.