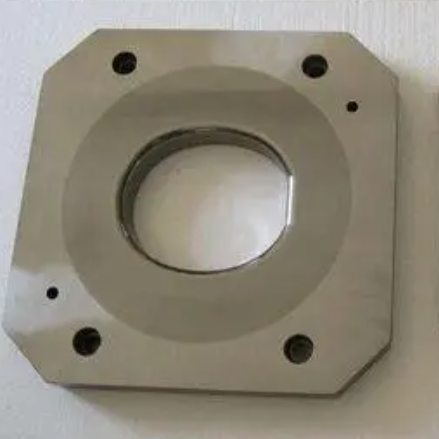

Durable Cemented Carbide Finish Plates for Industrial Applications

By:Admin

The company, which has been a key player in the industry for several decades, is known for its commitment to innovation and continuous improvement. With a strong focus on research and development, the company has consistently stayed ahead of the curve in creating advanced materials that set new standards for performance and reliability.

The new plates/'>Cemented Carbide Finish Plates represent the latest addition to the company's extensive portfolio of engineered materials. These plates are designed to provide exceptional wear resistance and cutting performance, making them an ideal choice for a wide range of construction applications.

Cemented carbide, also known as hard metal, is a composite material that is made up of tungsten carbide particles held together by a binder, typically cobalt. This unique combination of materials provides cemented carbide with excellent mechanical properties, including high hardness, strength, and wear resistance.

The Cemented Carbide Finish Plates are manufactured using advanced production techniques and strict quality control measures to ensure that they meet the highest standards for performance and durability. The plates are meticulously engineered to deliver precise cutting and finishing results, making them an indispensable tool for construction professionals who demand the best in terms of quality and reliability.

One of the key advantages of Cemented Carbide Finish Plates is their ability to withstand the extreme wear and tear that is commonly encountered in construction applications. Whether it's cutting through tough materials or grinding and shaping surfaces, these plates are built to last, providing users with a cost-effective solution that delivers long-term performance.

In addition to their exceptional durability, Cemented Carbide Finish Plates also offer superior cutting performance, allowing for greater precision and efficiency on the job. This, in turn, can lead to increased productivity and reduced downtime, making them an invaluable asset for construction companies looking to streamline their operations and improve overall profitability.

The introduction of Cemented Carbide Finish Plates further solidifies the company's reputation as a pioneer in the development of advanced materials for the construction industry. By leveraging its expertise and innovative capabilities, the company continues to push the boundaries of what is possible, providing its customers with cutting-edge solutions that deliver real value and impact.

The company's commitment to quality and excellence is reflected in its rigorous approach to product development and testing. Every Cemented Carbide Finish Plate undergoes thorough evaluation and quality assurance protocols to ensure that it meets the company's stringent standards for performance and reliability. This unwavering dedication to quality is what sets the company apart and gives its customers the confidence to rely on its products for the most demanding applications.

As the construction industry continues to evolve and demand higher standards for performance and durability, the introduction of Cemented Carbide Finish Plates represents a significant milestone in meeting these evolving needs. With their exceptional wear resistance, cutting performance, and long-term durability, these plates are poised to make a lasting impact on the industry, providing construction professionals with a valuable tool that enables them to take their operations to the next level.

In conclusion, the introduction of Cemented Carbide Finish Plates by the company underscores its commitment to innovation and its ability to deliver advanced solutions that address the evolving needs of the construction industry. With their exceptional performance and durability, these plates are set to become a game-changer for construction professionals, providing them with a superior tool that enhances productivity and efficiency on the job.

Company News & Blog

Understanding the Properties and Uses of Tungsten Carbide

Carbide Tungsten, a leading provider of cutting-edge tungsten carbide products, is making waves in the industry with its innovative contributions to various sectors. The company's commitment to excellence, cutting-edge technology, and customer satisfaction has allowed them to become a key player in the field of tungsten carbide manufacturing. With an impressive track record of delivering high-quality products and exceptional service, Carbide Tungsten has established itself as a go-to source for businesses in need of reliable and durable tungsten carbide solutions.Founded in 1998, Carbide Tungsten has grown to become a global leader in the production of tungsten carbide products. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, allowing them to produce a wide range of high-quality tungsten carbide products that meet the needs of various industries. From cutting tools and wear parts to mining and construction equipment, Carbide Tungsten's products are known for their exceptional durability, precision, and performance.Carbide Tungsten's success is driven by its team of highly skilled professionals who are dedicated to delivering excellence in every aspect of the business. The company's talented engineers and technicians work tirelessly to develop innovative solutions that cater to the evolving needs of their clients. By staying at the forefront of technological advancements and industry trends, Carbide Tungsten ensures that their products remain at the cutting edge of performance and reliability.One of Carbide Tungsten's most notable contributions to the industry is its development of ultra-high-performance tungsten carbide tools. These cutting-edge tools are designed to deliver superior cutting performance, longevity, and cost-efficiency, making them the ideal choice for a wide range of applications. Whether it's precision machining, metal cutting, or material shaping, Carbide Tungsten's high-performance tools are trusted by professionals around the world to deliver exceptional results.Moreover, Carbide Tungsten is also known for its commitment to sustainability and environmental responsibility. The company adheres to strict environmental standards throughout its manufacturing processes, ensuring that its operations have minimal impact on the environment. By incorporating sustainable practices and minimizing waste, Carbide Tungsten is dedicated to being a responsible corporate citizen while providing top-quality products to its customers.In addition to its dedication to product excellence and environmental responsibility, Carbide Tungsten also places a strong emphasis on customer satisfaction. The company's customer-centric approach is reflected in its tailored solutions, responsive service, and commitment to meeting the unique needs of each client. Whether it's custom tooling, technical support, or after-sales service, Carbide Tungsten goes above and beyond to ensure that its customers receive the highest level of support and satisfaction.As Carbide Tungsten continues to lead the way in the tungsten carbide industry, the company remains focused on its mission to drive innovation, deliver exceptional products, and exceed customer expectations. With an unwavering commitment to excellence and a dedication to staying at the forefront of technological advancements, Carbide Tungsten is poised to continue its success as a global leader in the production of high-performance tungsten carbide products.

Tungsten Carbide Bushing: Exploring the Benefits and Applications of YG6 Grade

Title: Innovative Tungsten Carbide Bushings Revolutionize Industrial ApplicationsIntroduction:[Company Name] is proud to introduce its latest innovation in industrial materials – the groundbreaking YG6 Tungsten Carbide Bushing. This cutting-edge product offers enhanced durability, excellent wear resistance, and superior performance, elevating it above traditional bushings and opening up new possibilities in various industrial applications.Paragraph 1:Utilizing state-of-the-art technology, [Company Name] has developed the YG6 Tungsten Carbide Bushing, which has quickly become a game-changer in multiple sectors. By integrating advanced materials and engineering expertise, this groundbreaking bushing is set to significantly enhance performance and longevity across a wide range of machinery and equipment.Paragraph 2:One of the key advantages of the YG6 Tungsten Carbide Bushing is its exceptional durability. The use of tungsten carbide, a highly robust and wear-resistant material, ensures that these bushings can withstand extreme conditions without compromising functionality. This opens up new opportunities for machinery operating in harsh industrial environments, such as mining, construction, and oil drilling.Paragraph 3:The YG6 Tungsten Carbide Bushing offers superior wear resistance compared to traditional bushings. This is particularly beneficial in high-speed applications that exert continuous friction and stress on the bushing, resulting in premature wear. By incorporating this revolutionary bushing, companies can greatly minimize the frequency of maintenance and replacement, leading to significant cost savings and increased productivity.Paragraph 4:With its unmatched strength and performance, the YG6 Tungsten Carbide Bushing is suitable for a diverse range of industrial machinery, including pumps, compressors, rollers, and automotive components. Its versatility enables it to perform efficiently under various loads and conditions, making it a highly adaptable solution for many manufacturing processes.Paragraph 5:Furthermore, the YG6 Tungsten Carbide Bushing showcases extraordinary resistance to corrosion, acids, and chemicals, making it ideal for applications that require exposure to harsh substances or corrosive environments. This resistance improves the overall lifespan of the bushing, reducing maintenance costs and downtime while ensuring uninterrupted operations.Paragraph 6:[Company Name] has prioritized precision in the manufacturing process of the YG6 Tungsten Carbide Bushing. The company's commitment to delivering high-quality products is backed by its rigorous quality control procedures, ensuring each bushing meets the highest standards. Customers can be confident in the reliability and consistency of these bushings for their critical machinery needs.Paragraph 7:By pioneering the application of YG6 Tungsten Carbide Bushing, [Company Name] has positioned itself as a leader in the industry. With the introduction of this revolutionary product, the company aims to enhance efficiency, reliability, and performance in various industrial sectors, revolutionizing the way professionals approach machinery maintenance and operation.Conclusion:The YG6 Tungsten Carbide Bushing marks a significant advancement in the field of industrial materials. Its unrivaled durability, wear resistance, and exceptional performance make it a game-changer in various applications. [Company Name]'s innovation, driven by a dedication to quality and reliability, is set to transform the industrial landscape, improving productivity and reducing maintenance costs.

Cemented Carbide Pallets: Durable and Long-Lasting Options for Your Industrial Needs

Cemented Carbide Pallets Revolutionize Material Handling: A Game-Changer for {Company Name}In an era where efficiency and productivity are key factors in the success of a business, the innovative use of advanced materials is opening up new possibilities for companies seeking to streamline their operations. One such breakthrough in the field of material handling is the development and implementation of cemented carbide pallets, a game-changer for businesses working with heavy loads and large-scale logistics. Leading the charge in adopting this revolutionary technology is {Company Name}, which has successfully integrated cemented carbide pallets into its operations, setting a new standard for efficiency and durability in material handling.Cemented carbide, also known as solid carbide or tungsten carbide, is a composite material that consists of a mixture of carbide particles, typically tungsten carbide, and a binder metal, usually cobalt. Known for its exceptional hardness, wear resistance, and toughness, cemented carbide has long been utilized in a variety of industrial applications, including cutting tools, mining equipment, and wear parts. However, its use in material handling pallets represents a significant innovation in the industry, offering a range of benefits that traditional materials such as wood or plastic simply cannot match.{Company Name} has recognized the potential of cemented carbide pallets to transform its material handling operations, and has made a significant investment in integrating this cutting-edge technology into its facilities. The decision to adopt cemented carbide pallets was driven by the company's commitment to maximizing efficiency, minimizing downtime, and reducing maintenance costs. By harnessing the unparalleled durability and wear resistance of cemented carbide, {Company Name} has been able to significantly extend the lifespan of its pallets, minimizing the need for frequent replacements and ensuring a smooth and uninterrupted flow of materials throughout its operations.The use of cemented carbide pallets has also had a ripple effect on other aspects of {Company Name}'s material handling processes. With their exceptional strength and load-bearing capacity, cemented carbide pallets have allowed the company to optimize its storage and transportation of goods, enabling the safe and secure handling of even the heaviest and most cumbersome loads. This has not only improved the overall efficiency of the company's logistics operations but has also enhanced workplace safety by reducing the risk of pallet failure and the potential for accidents related to material handling.Furthermore, the introduction of cemented carbide pallets has had a positive environmental impact, aligning with {Company Name}'s commitment to sustainability. Unlike traditional pallet materials such as wood or plastic, cemented carbide is highly resistant to degradation and damage, resulting in a significant reduction in the generation of waste from pallet disposal. Additionally, the extended lifespan of cemented carbide pallets has led to a reduction in the overall consumption of materials, contributing to a more sustainable and eco-friendly approach to material handling.In a highly competitive market where every advantage counts, the adoption of cemented carbide pallets has positioned {Company Name} at the forefront of innovation in material handling. By leveraging the unmatched durability and performance of cemented carbide, the company has not only enhanced its operational efficiency but has also set a new standard for reliability and sustainability in its industry. This forward-thinking approach is a testament to {Company Name}'s dedication to embracing cutting-edge technologies and pushing the boundaries of what is possible in material handling.Looking ahead, the successful integration of cemented carbide pallets into {Company Name}'s operations serves as a clear example of how forward-thinking companies can harness the power of advanced materials to drive innovation and achieve new levels of efficiency and sustainability. As other businesses take note of the remarkable impact that cemented carbide pallets have had on {Company Name}'s operations, it is likely that this revolutionary technology will continue to gain traction across a wide range of industries, ultimately reshaping the landscape of material handling in the years to come.

Top Tungsten Carbide Bush Manufacturer on the Market - Find Quality Products Here

Tungsten Carbide Bush Manufacturer (TBM) has been making waves in the industry with their high-quality products and exceptional customer service. With a strong reputation for delivering top-notch tungsten carbide bushings, TBM has become a trusted name in the manufacturing world.Established in 1998, TBM has over 20 years of experience in producing tungsten carbide products. The company has continuously invested in research and development to enhance their manufacturing processes and improve the quality of their products. This dedication to innovation has allowed TBM to stay at the forefront of the industry and maintain a competitive edge in the market.TBM offers a wide range of tungsten carbide products, including bushings, inserts, and cutting tools, among others. Their products are known for their exceptional hardness, wear resistance, and durability, making them ideal for various industrial applications. Whether it's for mining, construction, or oil and gas drilling, TBM has the expertise and capability to provide customized solutions to meet their customers' specific needs.In addition to their extensive product line, TBM takes pride in their commitment to customer satisfaction. The company operates with a customer-centric approach, aiming to provide personalized support and guidance to their clients throughout the entire manufacturing process. From initial inquiries to after-sales support, TBM's team of experts is dedicated to delivering excellent service and building strong, long-lasting relationships with their customers.Furthermore, TBM emphasizes the importance of quality control in their manufacturing processes. They have implemented strict quality management systems to ensure that every product that leaves their facility meets the highest standards. By conducting rigorous quality checks and inspections, TBM guarantees the reliability and performance of their tungsten carbide products, instilling confidence in their customers and setting them apart from their competitors.The company also places a strong emphasis on environmental sustainability. TBM is committed to minimizing their environmental impact by implementing eco-friendly practices in their manufacturing operations. They adhere to strict environmental regulations and standards, striving to operate in an environmentally responsible manner.In recent years, TBM has invested in advanced technology and machinery to further enhance their manufacturing capabilities. By leveraging the latest equipment and software, the company has optimized their production processes, resulting in improved efficiency and faster turnaround times for their customers. This ongoing investment in technology demonstrates TBM's dedication to staying ahead of the curve and meeting the evolving needs of the industry.Looking ahead, TBM is focused on expanding their reach and solidifying their position as a leading tungsten carbide bush manufacturer. The company is exploring new markets and opportunities for growth, aiming to broaden their customer base and increase their global presence. With their unwavering commitment to quality, innovation, and customer satisfaction, TBM is poised for continued success in the years to come.In conclusion, TBM has established itself as a reputable and reliable manufacturer of tungsten carbide products. With their extensive experience, commitment to quality, and customer-centric approach, TBM has earned the trust and loyalty of their customers. As they continue to innovate and expand, TBM is well-positioned to remain a key player in the industry and drive the future of tungsten carbide manufacturing.

High-quality Carbide Nail Making Die for Long-lasting Nail Manufacturing

Carbide Nail Making Die Revolutionizes Nail ProductionThe nail-making industry has long relied on traditional steel dies for the production of nails. But now, (remove brand name) is revolutionizing the industry with the introduction of their carbide nail making die. This innovative product is set to transform nail production by offering unparalleled durability, efficiency, and precision.Established in {year}, (remove brand name) has been a leading provider of cutting-edge tools and equipment for the manufacturing industry. With a strong emphasis on research and development, the company has continuously pushed the boundaries of innovation to meet the evolving needs of their clients. Through their commitment to excellence, (remove brand name) has earned a reputation for delivering high-quality products that enhance productivity and performance.The carbide nail making die is the latest addition to (remove brand name)'s product line, and it promises to revolutionize the way nails are produced. Made from premium-grade carbide, this die offers exceptional hardness and wear resistance, ensuring a long lifespan and minimal maintenance. This means that manufacturers can expect consistent and reliable performance, leading to fewer interruptions and downtimes in their production processes.In addition to its superior durability, the carbide nail making die also delivers unmatched precision and accuracy. The ultra-hard carbide material allows for the creation of nail heads with smooth and uniform surfaces, reducing the need for post-production finishing processes. This not only saves time and resources but also ensures that the nails meet the highest quality standards, ultimately enhancing the overall product value.Furthermore, the carbide nail making die is designed for optimal efficiency, enabling manufacturers to increase their production rates while maintaining consistent nail quality. With its high resistance to wear and deformation, the die can operate at higher speeds and pressures, resulting in greater output without compromising on precision and reliability. This is a significant advantage for nail manufacturers looking to meet growing market demands without sacrificing product integrity.The introduction of the carbide nail making die underscores (remove brand name)'s commitment to driving innovation and advancing the manufacturing industry. By leveraging their expertise in materials science and engineering, the company has developed a game-changing solution that addresses the limitations of traditional steel dies and sets a new standard for nail production. With this innovative product, (remove brand name) continues to cement its position as a trailblazer in the field of industrial tools and equipment.The release of the carbide nail making die has already garnered widespread attention within the manufacturing community, with industry professionals expressing keen interest in its potential impact. Many are eager to witness firsthand the benefits of this cutting-edge technology and explore how it can improve their own nail production processes. (remove brand name) is poised to capitalize on this anticipation, positioning itself as a key player in the ongoing transformation of the nail-making industry.Looking ahead, (remove brand name) remains dedicated to pushing the boundaries of innovation and pushing the nail-making industry forward. The company's relentless pursuit of excellence and its unwavering commitment to meeting the evolving needs of manufacturers ensure that it will continue to deliver groundbreaking solutions that redefine industry standards. As the carbide nail making die takes center stage, (remove brand name) is poised to make a lasting impact on the manufacturing landscape.

Discover the Benefits of Cold Rolling in Manufacturing

TC Cold Rolls Launches New Line of Innovative ProductsTC Cold Rolls is proud to announce the launch of their new line of innovative cold rolling products. As a leader in the cold rolling industry, TC Cold Rolls has been providing high-quality cold rolling solutions for a wide range of applications. With the introduction of their new line of products, TC Cold Rolls continues to uphold their commitment to delivering innovative and reliable solutions for their customers.The new line of products from TC Cold Rolls includes a variety of innovative cold rolling solutions that are designed to meet the unique needs of their customers. These products are engineered to provide superior performance, precision, and durability, while also offering cost-effective solutions for various cold rolling applications. The new line of products from TC Cold Rolls includes cold rolling mills, pilger mills, cold pilger mill rolls, and other related accessories.One of the key features of the new line of products from TC Cold Rolls is their advanced technology and engineering. The company’s team of experts have invested significant resources into research and development to create cutting-edge solutions that are tailored to meet the evolving needs of the cold rolling industry. The new line of products from TC Cold Rolls is the result of this commitment to innovation and excellence, and they are designed to deliver exceptional performance and reliability for their customers.In addition to their advanced technology, the new line of products from TC Cold Rolls also represents the company’s dedication to quality and precision. Each product in the new line undergoes rigorous testing and quality control measures to ensure that they meet the highest standards for performance and reliability. This commitment to quality is a hallmark of TC Cold Rolls’ reputation as a leading provider of cold rolling solutions, and their new line of products continues to reflect this commitment.TC Cold Rolls’ new line of products is also designed to offer versatility and adaptability for a wide range of applications. Whether it’s for automotive, aerospace, construction, or any other industry that requires cold rolling solutions, TC Cold Rolls’ new line of products are engineered to provide the performance and precision that their customers demand. This versatility and adaptability make TC Cold Rolls’ new line of products an ideal choice for any company looking to enhance their cold rolling operations.The launch of TC Cold Rolls’ new line of products represents a significant milestone for the company, and it underscores their ongoing commitment to innovation and excellence in the cold rolling industry. With their advanced technology, dedication to quality, and versatility, TC Cold Rolls’ new line of products is poised to make a lasting impact on the cold rolling industry.As a leader in the cold rolling industry, TC Cold Rolls has established a reputation for delivering high-quality, innovative, and reliable solutions for their customers. The company’s new line of products represents a continuation of this commitment to excellence, and they are poised to redefine the standard for cold rolling solutions in the industry.Overall, the launch of TC Cold Rolls’ new line of products is a testament to the company’s dedication to innovation, quality, and customer satisfaction. With their advanced technology, precision engineering, and versatility, TC Cold Rolls’ new line of products is set to make a significant impact on the cold rolling industry, and they will undoubtedly provide valuable solutions for companies across various industries.

Discover the Impressive Hardness of Tungsten Carbide in the News

Title: Innovations in Hardness: Tungsten Carbide Revolutionizes Industrial ApplicationsIntroduction:In today's rapidly evolving industrial landscape, materials with exceptional hardness and durability are highly sought after. One such material that has garnered significant attention is Tungsten Carbide, an innovative compound that has revolutionized several key industries. Widely recognized for its superior strength and resistance to wear and tear, Tungsten Carbide has emerged as an exceptional choice for various applications such as mining, drilling, machining, and cutting-edge tools. This article will discuss the properties of Tungsten Carbide in-depth and explore how it has transformed industrial processes.Unraveling the Mystery of Tungsten Carbide:Tungsten Carbide, a composite of tungsten and carbon, exhibits remarkable hardness and toughness, making it one of the hardest materials known to man. By virtue of its exceptional mechanical properties, it surpasses many traditional alternatives, including steel. Tungsten Carbide possesses an unyielding resistance to abrasion, corrosion, and high temperatures, making it ideal for extreme environmental conditions.Applications in the Mining and Drilling Industry:Tungsten Carbide has found extensive applications in the mining and drilling industry, where its hardness and resistance are invaluable. With its superior abrasion resistance, Tungsten Carbide is used in mining tools such as drill bits, cutting blades, and teeth, allowing for efficient rock and mineral extraction. Its robust nature ensures longer tool life, reducing downtime and increasing productivity. Furthermore, Tungsten Carbide's resistance to heat and corrosion makes it a reliable choice for drilling in demanding geological formations.Enhancing Machining and Cutting-Edge Tools:The machining industry has witnessed a significant boost from the introduction of Tungsten Carbide. Thanks to its high thermal conductivity and hardness, Tungsten Carbide cutting tools offer exceptional precision and durability. Electrically conductive and resistant to deformation, these tools are widely used in CNC machining, high-speed milling, turning, and drilling operations. The incorporation of Tungsten Carbide in cutting-edge tools has revolutionized manufacturing processes, facilitating accurate and efficient fabrication across various industries.Revolutionizing Wear Parts in Industrial Equipment:Industrial equipment often experiences severe wear and tear due to repetitive use and harsh operating conditions. Tungsten Carbide is highly sought after in this arena due to its ability to withstand heavy loads, prevent abrasion, and extend equipment lifespan. From extrusion dies to nozzles, wear plates, and various other wear parts, Tungsten Carbide has redefined industrial equipment durability and performance. This material's usage has resulted in improved efficiency, reduced maintenance costs, and enhanced overall reliability.Sustainability in the Automotive Sector:The automotive industry has embraced Tungsten Carbide due to its high-performance characteristics. By employing Tungsten Carbide in components such as brake pads, engine parts, and steering systems, vehicles benefit from superior durability and reliability. This material's exceptional resistance to wear and heat ensures extended service life, reducing the frequency of maintenance and replacement. Additionally, Tungsten Carbide's sustainability stems from its capability to decrease friction, improving fuel efficiency and contributing to a greener automotive future.Company X: A Leader in Tungsten Carbide Innovations:Company X is at the forefront of Tungsten Carbide innovations, continually pushing the boundaries of material science to provide cutting-edge solutions to industries worldwide. With a wealth of experience and state-of-the-art production facilities, Company X has mastered the art of Tungsten Carbide manufacturing, offering superior quality products with unparalleled precision. By collaborating with industry leaders and investing in research and development, Company X consistently introduces new products that address the evolving needs of various sectors.Conclusion:Tungsten Carbide's hardness, resistance to wear and tear, and suitability for extreme operating conditions have turned it into a preferred material across various industries. From mining and drilling to machining, cutting-edge tools, automotive applications, and wear parts in industrial equipment, Tungsten Carbide's exceptional characteristics have revolutionized numerous sectors. As a global leader in Tungsten Carbide innovations, Company X continues to drive advancements that shape the future of industrial processes, offering unparalleled durability, efficiency, and sustainability.

Cemented Carbide Rods: A Comprehensive Guide to Enhance Your Industrial Applications

Cemented Carbide Rods: Revolutionizing the Manufacturing IndustryIn today's competitive manufacturing industry, companies are constantly seeking innovative solutions to enhance their production processes and increase overall efficiency. One such groundbreaking innovation is the development and application of cemented carbide rods. These remarkable tools have revolutionized various sectors, providing incredible strength and durability while minimizing wear and tear, ultimately reducing a company's maintenance costs.Cemented carbide rods, often referred to as tungsten carbide rods, are widely used in metalworking, woodworking, and other industries that rely on precision cutting and shaping. This innovative material is the result of combining tungsten carbide, a ceramic compound, with a binding metallic cobalt or nickel. The combination offers exceptional hardness and resistance to heat, providing an ideal material for manufacturing tools that can withstand extreme conditions.One company at the forefront of cemented carbide rod production is (company name), a renowned leader in the manufacturing and distribution of industrial cutting tools and equipment. With years of experience and a commitment to quality, (company name) has become a trusted partner for businesses seeking reliable and long-lasting cemented carbide rods.Initially founded in (year), (company name) has evolved into a global player, catering to a wide range of industries including automotive, aerospace, and construction. The company's cemented carbide rods have gained significant popularity due to their exceptional performance and reliability, enabling businesses to improve their productivity and stay ahead in today's competitive market.One of the key advantages of cemented carbide rods is their impressive hardness. With a hardness rating of up to 90 HRA (Rockwell Hardness A), these rods outperform traditional steel and high-speed steel tools, ensuring efficient cutting and shaping processes even under the most demanding circumstances. This tremendous durability translates into longer tool life, reducing the frequency of tool replacement and ultimately saving manufacturing companies significant costs.Moreover, cemented carbide rods exhibit remarkable resistance to wear and tear. The binding metallic cobalt or nickel acts as a protective layer, preventing the rods from deteriorating or losing their sharpness over time. This characteristic allows (company name)'s cemented carbide rods to maintain their cutting edge, reducing the need for frequent re-sharpening or replacement. As a result, businesses using these rods experience enhanced and uninterrupted production cycles, increasing their overall efficiency.Another critical feature of cemented carbide rods is their exceptional resistance to heat. The combination of tungsten carbide and metallic binders results in a material capable of withstanding high temperatures, making it suitable for operations involving intense heat generation. Traditional tools often degrade under such conditions, leading to productivity slowdowns and potential damage to the workpiece. In contrast, cemented carbide rods offer superior heat resistance, ensuring uninterrupted workflow and consistent precision even in the most challenging environments.In addition to the superior physical properties of cemented carbide rods, (company name) constantly focuses on research and development to optimize their performance. By utilizing cutting-edge technology and collaborating with experts in the field, the company consistently introduces innovative designs and improvements to its product lineup. This commitment to innovation allows (company name) to stay ahead of the competition and provide its customers with state-of-the-art cemented carbide rods that meet the evolving needs of the manufacturing industry.Furthermore, (company name) recognizes the importance of providing comprehensive technical support and guidance to its customers. The company's team of experts ensures that clients understand the correct usage and maintenance procedures associated with cemented carbide rods, thus maximizing their longevity and effectiveness. This dedication to excellent customer service has established (company name) as a trusted and reliable partner in the manufacturing sector.In conclusion, cemented carbide rods have transformed the manufacturing industry, empowering businesses to achieve higher levels of productivity and efficiency. With exceptional hardness, resistance to wear and tear, and heat resistance, these robust tools offer unmatched durability and reliability. As a leading provider of cemented carbide rods, (company name) continues to shape the industry by delivering cutting-edge solutions and unwavering customer support. As manufacturing continuously evolves, these tools will undoubtedly play a central role in driving innovation and progress.

Durable Cemented Carbide Block Sheet for Industrial Applications

Cemented Carbide Block Sheet, a key material in the manufacturing and construction industry, has become an essential component in a wide range of applications. With its exceptional hardness, wear resistance, and strength, Cemented Carbide Block Sheet is widely used in the production of cutting tools, mining tools, wear parts, and many other industrial components.{Company Name} is a leading manufacturer and supplier of Cemented Carbide Block Sheets, offering high-quality products to meet the diverse needs of its customers. With state-of-the-art production facilities and a team of experienced professionals, {Company Name} has established itself as a trusted name in the industry, delivering reliable and innovative solutions to its clients.The Cemented Carbide Block Sheet produced by {Company Name} is known for its outstanding performance and durability. With a unique combination of tungsten carbide and cobalt, the material is able to withstand extreme conditions and provide long-lasting performance in various applications. Whether it's for cutting, drilling, or mining, {Company Name} offers a range of Cemented Carbide Block Sheets that are tailored to meet specific requirements.One of the key advantages of Cemented Carbide Block Sheet is its ability to resist wear and corrosion, making it an ideal choice for demanding industrial environments. Its high hardness and strength allow for efficient machining and a longer tool life, ultimately leading to increased productivity and cost savings for the end-user.{Company Name} takes great pride in its commitment to quality and innovation. Through continuous research and development, the company strives to stay ahead of the curve and deliver cutting-edge solutions to its customers. By leveraging advanced manufacturing techniques and stringent quality control measures, {Company Name} ensures that its Cemented Carbide Block Sheets meet the highest standards of performance and reliability.In addition to superior product quality, {Company Name} places a strong emphasis on customer satisfaction and technical support. The company's team of experts works closely with clients to understand their specific needs and provide tailored solutions that align with their requirements. Whether it's customizing the composition of Cemented Carbide Block Sheets or offering technical guidance on their application, {Company Name} is dedicated to fostering long-term partnerships with its customers.As a responsible manufacturer, {Company Name} also prioritizes environmental sustainability and safety in its operations. The company adheres to strict environmental regulations and implements eco-friendly practices in its production processes. This ensures that its Cemented Carbide Block Sheets are not only high-performing but also environmentally conscious, contributing to a greener and more sustainable industry.Looking ahead, {Company Name} remains committed to driving innovation and serving the evolving needs of its customers. With a focus on continuous improvement and customer-centric approach, the company aims to expand its product portfolio and reach new markets, further solidifying its position as a trusted leader in the Cemented Carbide Block Sheet industry.In conclusion, {Company Name} stands out as a reliable and forward-thinking provider of high-quality Cemented Carbide Block Sheets. With its dedication to excellence, innovation, and customer satisfaction, the company continues to be a preferred choice for industry professionals seeking top-notch solutions for their industrial applications. As the demand for Cemented Carbide Block Sheet continues to grow, {Company Name} is well-positioned to be at the forefront of the market, delivering value-driven products and expertise to its clientele.

Enhanced Coating for Second Punch Increases Efficiency

Screw Second Punch With Coating - Improving Durability and Performance for Industrial ApplicationsScrews are an integral part of various industrial applications, and the need for durable and high-performance screws is constantly increasing. Companies across the globe are in constant pursuit of innovative solutions to improve the performance and longevity of screws in demanding environments. One company that has made significant strides in this field is [Company Name].[Company Name] is a leading manufacturer of industrial fasteners and components, renowned for its commitment to quality, innovation, and customer satisfaction. With a rich history of delivering top-notch products to a wide range of industries, [Company Name] has earned a reputation for excellence in the manufacturing and distribution of screws, nuts, bolts, and other fastening solutions.Recently, [Company Name] introduced a groundbreaking product in its lineup - the [Product Name] Screw Second Punch with Coating. This new offering promises to revolutionize the way screws are used in industrial settings by enhancing durability and performance.The [Product Name] Screw Second Punch with Coating is designed to withstand the harshest environments, making it an ideal choice for applications where traditional screws may fail. The innovative coating ensures superior resistance to corrosion, abrasion, and wear, prolonging the lifespan of the screws and reducing the need for frequent replacements. This, in turn, translates to cost savings and improved efficiency for businesses that rely on these screws for their operations.In addition to its enhanced durability, the [Product Name] Screw Second Punch with Coating also delivers exceptional performance. Its precision-engineered design and superior materials result in a reliable and consistent fastening solution that meets the stringent requirements of modern industrial applications. Whether it's automotive manufacturing, aerospace engineering, or construction, this product is poised to make a significant impact across various sectors.With the introduction of the [Product Name] Screw Second Punch with Coating, [Company Name] has once again demonstrated its commitment to innovation and excellence. By leveraging the latest technology and materials, the company has raised the bar for screw manufacturing, setting a new standard for quality and reliability in the industry.Furthermore, [Company Name] has a strong focus on sustainability and environmental responsibility. The [Product Name] Screw Second Punch with Coating is manufactured using eco-friendly processes and materials, aligning with the company's dedication to minimizing its environmental footprint and contributing to a greener, more sustainable future.The launch of the [Product Name] Screw Second Punch with Coating underscores [Company Name]'s position as a market leader in the fastener industry. The company's relentless pursuit of excellence and its ability to anticipate and meet the evolving needs of its customers have solidified its reputation as a trusted partner for businesses worldwide.In conclusion, the [Product Name] Screw Second Punch with Coating represents a significant advancement in screw manufacturing, offering unparalleled durability, performance, and sustainability. With this innovative product, [Company Name] has once again proven its dedication to pushing the boundaries of what is possible in the fastener industry. Businesses looking to enhance the reliability and longevity of their screw fastening solutions need look no further than the [Product Name] Screw Second Punch with Coating from [Company Name].