Durable and Tough Tungsten Carbide: A Closer Look at Its Hardness

By:Admin

[Brand Name] has a long history of innovation and excellence in the field of carbide tools. With state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, they have been able to consistently produce some of the highest quality carbide products on the market. Their commitment to quality and precision has made them a trusted partner for many companies in a variety of industries.

One of the key features of [Brand Name]'s carbide tools is their incredible hardness. Tungsten carbide is one of the hardest materials in the world, second only to diamond. This makes it incredibly resistant to wear and ensures that it maintains its sharpness and precision for a long time. This is crucial for industries that rely on precise cutting and shaping, as it means that [Brand Name]'s carbide tools can deliver consistent and reliable performance, even in the most demanding applications.

In addition to their impressive hardness, [Brand Name]'s carbide tools are also known for their exceptional strength and durability. This makes them an ideal choice for applications that involve heavy-duty cutting, drilling, and shaping. Whether it's in the harsh environment of a mining operation or the precision work of a high-tech manufacturing facility, [Brand Name]'s carbide tools can be counted on to deliver exceptional performance.

Another key advantage of [Brand Name]'s carbide tools is their versatility. They can be used to cut a wide range of materials, from soft woods to tough metals, and everything in between. This makes them a valuable tool for a variety of industries, as it means that companies can rely on a single tool for a wide range of applications. This versatility not only saves time and money, but also minimizes the need for multiple tools, simplifying operations and streamlining processes.

[Brand Name]'s commitment to quality doesn't stop at the production of their carbide tools. They also offer a range of support services to ensure that their customers get the most out of their products. This includes expert technical support, training, and maintenance services to help companies maximize the performance and lifespan of their carbide tools. This level of support is just one of the reasons why [Brand Name] has built a reputation for being a trusted and reliable partner for businesses around the world.

In conclusion, the introduction of [Brand Name]'s new line of tungsten carbide tools is sure to make a big impact in the industry. With their incredible hardness, strength, durability, and versatility, these tools are a valuable addition to any company's arsenal. Whether it's for cutting, drilling, shaping, or any other application, companies can rely on the exceptional performance and reliability of [Brand Name]'s carbide tools. And with their commitment to quality and support, [Brand Name] is a partner that businesses can trust to help them succeed.

Company News & Blog

Applications of Tungsten Carbide: A Versatile Industrial Material

Title: Tungsten Carbide: Revolutionizing Industries with Unparalleled VersatilityIntroduction:In the world of industrial applications, Tungsten Carbide has emerged as a game-changing material renowned for its exceptional hardness, durability, and versatility. With its remarkable properties and myriad of applications, this composite material has found its way into various industries, transforming manufacturing processes and enhancing product performance. This article delves into the multifaceted use of Tungsten Carbide and its profound impact on different sectors of the global economy.1. Automotive Industry:From precision cutting tools to durable automotive components, Tungsten Carbide is revolutionizing the automotive sector. In cutting-edge engine manufacturing, Tungsten Carbide inserts in tooling systems play a vital role in delivering precise and high-speed machining with superior surface finish. Mechanical seals made from this robust material ensure leak-free operation in automotive water pumps and ensure prolonged service life. Moreover, the use of Tungsten Carbide in brake pads and clutch facings improves braking performance and enhances durability, ensuring driver safety.2. Oil and Gas Industry:The oil and gas industry heavily relies on Tungsten Carbide due to its exceptional wear resistance and high-temperature stability. Exploration and drilling operations utilize hard-facing applications, such as drill bits, to withstand extreme working conditions while maximizing drilling efficiency. Furthermore, Tungsten Carbide components in downhole tools, such as stabilizers and wear-resistant valves, endure the challenging environment and enhance operational reliability. By offering superior resistance to erosion and corrosion, Tungsten Carbide ensures increased productivity and reduced downtime in the oil and gas sector.3. Mining and Construction:In the mining and construction sectors, where equipment operates in harsh environments, Tungsten Carbide plays a crucial role in enhancing equipment longevity and efficiency. The use of Tungsten Carbide in drill bits, augers, and tooling systems allows for improved penetration rates and extended tool life. Excavation buckets and teeth made from this material withstand abrasion from rocks and other challenging geological conditions, reducing maintenance costs and increasing productivity. The mining industry benefits greatly from the advanced performance and reliability offered by Tungsten Carbide, enabling extraction operations to occur seamlessly and efficiently.4. Metalworking and Tooling:Tungsten Carbide is widely acclaimed in the metalworking industry for its exceptional resistance to wear, deformation, and high temperatures. Cutting inserts and end mills made from this composite material offer superior cutting speed, precision, and surface finish, thereby enhancing overall machining productivity. Tungsten Carbide tooling systems also find extensive applications in the woodworking industry, where they deliver increased cutting efficiency and improved finish quality. These properties make Tungsten Carbide an indispensable choice for manufacturing sectors, guaranteeing efficiency and precision in every operation.5. Electronics and Semiconductors:In the rapidly advancing field of electronics and semiconductors, Tungsten Carbide is sought after for its electrical conductivity and resistance to wear and heat. The material is widely used in the production of semiconductor dies, integrated circuit packages, and wire bonding tools, ensuring reliable and durable electronic devices. Tungsten Carbide's remarkable electrical conductivity, coupled with its high strength, makes it an indispensable choice for electronics manufacturers.Conclusion:Tungsten Carbide's unique blend of hardness, durability, and versatility has transformed various industries and manufacturing processes worldwide. From automotive components to oil and gas equipment, mining tools to metalworking applications, and electronics to semiconductors, this exceptional material has proven to be an invaluable asset for enhancing product performance, increasing productivity, and reducing maintenance costs. As technological advancements continue to shape our world, Tungsten Carbide remains at the forefront, playing a pivotal role in shaping a more efficient and sustainable future across multiple sectors.

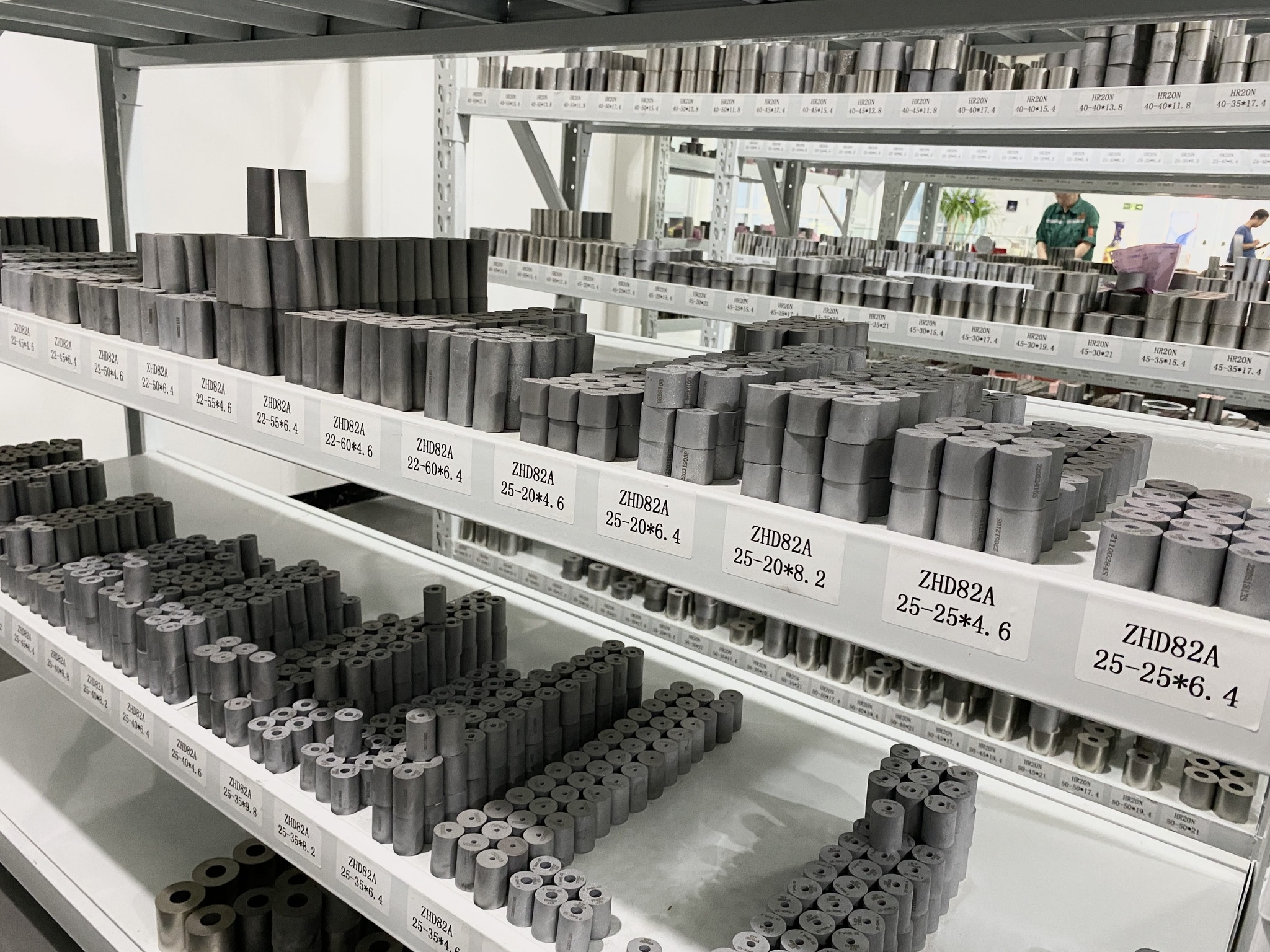

High-Quality Tungsten Carbide Sleeve Bearing Bushing Dies for Industrial Applications

The Tungsten Carbide Sleeve Bearing Bushing Dies have become the latest innovation in the manufacturing industry, offering exceptional durability and performance. These precision-engineered products have been designed to withstand the most challenging industrial environments, making them an essential component for a wide range of applications.Developed by a leading manufacturer in the industry, {}, these Tungsten Carbide Sleeve Bearing Bushing Dies have quickly gained a reputation for their superior quality and reliability. The company is known for its commitment to innovation and excellence, continuously pushing the boundaries of what is possible in the field of engineering and manufacturing.The Tungsten Carbide Sleeve Bearing Bushing Dies are made from high-quality tungsten carbide, a material known for its extraordinary toughness and resistance to wear and tear. This makes them an ideal solution for applications that involve high levels of friction and abrasion, providing a long-lasting and reliable performance that is unmatched by other materials.One of the key advantages of these Tungsten Carbide Sleeve Bearing Bushing Dies is their ability to maintain their shape and dimension even under extreme pressure and temperature conditions. This ensures that they can deliver consistent and accurate results, making them an invaluable asset for industries that require precision and reliability.In addition to their exceptional durability, the Tungsten Carbide Sleeve Bearing Bushing Dies are also designed to minimize friction and heat generation, which helps to reduce wear and tear on the equipment and prolong its lifespan. This results in cost savings for businesses, as they can minimize the need for frequent replacements and repairs.The company behind these innovative products has invested heavily in research and development to ensure that they meet the highest standards of performance and reliability. Their team of experienced engineers and technicians have worked tirelessly to optimize the design and manufacturing process, resulting in a product that sets new benchmarks for quality and durability.Furthermore, the company is committed to providing personalized solutions to meet the specific needs of their customers. They offer a range of customization options for the Tungsten Carbide Sleeve Bearing Bushing Dies, allowing businesses to tailor the products to their unique requirements. This flexibility has made them a preferred partner for many companies across various industries.With their unwavering focus on quality and innovation, the company has established itself as a trusted leader in the manufacturing industry. They have built a strong reputation for delivering products that consistently exceed expectations, earning the trust and loyalty of their customers.As the demand for high-performance, durable components continues to grow, the Tungsten Carbide Sleeve Bearing Bushing Dies are poised to become a staple in the manufacturing industry. Their unmatched durability, reliability, and performance make them a valuable investment for businesses looking to enhance their operations and productivity.In conclusion, the Tungsten Carbide Sleeve Bearing Bushing Dies developed by the company {} represent a significant breakthrough in the field of engineering and manufacturing. Their exceptional durability, reliability, and performance set new standards for the industry, making them an essential component for a wide range of applications. With their unwavering commitment to innovation and quality, the company has positioned itself as a leader in the manufacturing industry, earning the trust and loyalty of customers around the world.

Discover the Amazing Benefits of Tungsten Carbide Drawing Dies

[Introduction]Tungsten Carbide Drawing Die: Pioneering Innovation in the Wire Manufacturing Industry[Company Introduction][Remove brand name] is a leading player in the carbide die industry, offering cutting-edge solutions and technological advancements in wire manufacturing. With years of experience and expertise, they have become a trusted name, providing high-quality tungsten carbide drawing dies to meet the ever-evolving needs of various industries.[News Content][Remove brand name], a renowned player in the carbide die industry, continues to pave the way for innovation, introducing the latest tungsten carbide drawing die technology. This groundbreaking advancement in wire manufacturing promises to revolutionize various industries' production processes, ensuring efficiency, durability, and unmatched precision.Tungsten carbide, known for its exceptional hardness and wear resistance, has become the material of choice for drawing dies. This compound, composed of equal parts of tungsten and carbon atoms, is stronger than pure steel and can withstand extreme pressure and temperatures, making it ideal for wire drawing applications.Drawing dies are crucial components in the wire manufacturing process, responsible for reducing the diameter of wire rods or tubes. By passing the material through a series of dies, the diameter is progressively decreased, resulting in the desired wire size. The accuracy and quality of these dies directly impact the final product's surface finish, tensile strength, and dimensional control.[Remove brand name]'s tungsten carbide drawing dies exhibit exceptional performance attributes, which set them apart from traditional dies. With their proprietary manufacturing techniques and cutting-edge machinery, they have been able to achieve remarkable results. The dies are designed with precision to ensure consistent wire drawing performance, minimizing the risk of defects and ensuring superior surface finish.In addition to their outstanding performance, these drawing dies have an extended lifespan, contributing to cost savings in the long run. The superior hardness and wear resistance of tungsten carbide enable the dies to withstand prolonged use and reduce the need for frequent replacement. This not only saves on downtime but also enhances overall productivity.Furthermore, [Remove brand name]'s tungsten carbide drawing dies have proven to be versatile, catering to the diverse needs of wire manufacturers across various industries. Whether it is copper, aluminum, steel, or even specialized alloys, these drawing dies have demonstrated exceptional performance and reliability across the board.The introduction of this innovative technology has been met with enthusiasm from wire manufacturers worldwide. The unrivaled quality and performance offered by [Remove brand name] have led to increased productivity and improved product quality for countless companies.Moreover, this breakthrough advancement aligns with the growing demand for sustainable manufacturing practices. By extending the lifespan of drawing dies, [Remove brand name] helps reduce waste and significantly minimizes environmental impact.As the wire manufacturing industry continues to evolve, [Remove brand name]'s tungsten carbide drawing dies remain at the forefront of technological innovations. Their commitment to excellence and customer satisfaction ensures that they will continue to be a leading force in the carbide die industry, revolutionizing wire manufacturing processes and driving progress in various sectors.[Conclusion]With the introduction of tungsten carbide drawing dies, [Remove brand name] has solidified its position as an industry pioneer, offering cutting-edge solutions that enhance wire manufacturing processes. The exceptional durability, precision, and versatility of these dies are driving productivity and enabling companies to deliver superior quality products. As the demand for sustainable manufacturing practices increases, [Remove brand name]'s tungsten carbide drawing dies are set to play a vital role in shaping a greener and more efficient future.

Top Quality Cemented Carbide Cutting Tools for Precision Machining

Cemented Carbide Cutting Tools Market is expected to grow at a CAGR of 6.6% during the forecast period. The market is experiencing growth owing to the increasing demand for high-quality cutting tools across various industries such as automotive, aerospace, and construction. Cemented carbide cutting tools, also known as hard metal cutting tools, are used for cutting, drilling, milling, and turning operations in the manufacturing sector.Cemented carbide cutting tools are made by combining tungsten carbide with cobalt. Tungsten carbide provides high hardness and wear resistance, while cobalt acts as a binder to hold the tungsten carbide particles together. These tools are known for their ability to withstand high temperatures and have excellent cutting performance, making them a popular choice in the metal cutting industry.The global cemented carbide cutting tools market is highly competitive with the presence of several key players. One such prominent player is [Company Name], a leading manufacturer and supplier of high-quality cutting tools. The company has a wide range of cemented carbide cutting tools that are designed to meet the diverse needs of its customers across various industries.[Company Name] has a strong focus on research and development to continuously improve the performance and quality of its cutting tools. The company's state-of-the-art manufacturing facilities and advanced technology allow it to produce cutting-edge products that are at the forefront of the industry. With a team of experienced engineers and experts, [Company Name] is dedicated to providing innovative solutions to its customers and ensuring their satisfaction.In addition to its cutting-edge products, [Company Name] also offers excellent customer service and technical support to its clients. The company's team of skilled professionals is well-equipped to assist customers with their cutting tool needs, from product selection to application support. By building strong relationships with its customers, [Company Name] has established itself as a trusted partner in the industry.As the demand for cemented carbide cutting tools continues to rise, [Company Name] is well-positioned to capitalize on the market growth. The company's commitment to quality, innovation, and customer satisfaction sets it apart from its competitors and solidifies its position as a leader in the industry.In conclusion, the global market for cemented carbide cutting tools is poised for significant growth in the coming years, driven by the growing demand for high-performance cutting tools in various industries. [Company Name], with its extensive range of cutting-edge products and excellent customer service, is well-prepared to capitalize on this growth and solidify its position as a key player in the market. With a strong focus on innovation and customer satisfaction, [Company Name] is set to continue its success and leadership in the cemented carbide cutting tools industry.

Boost Your SEO Success with Innovative Mill Rolls

[Company Introduction]{Company Name}, a leading provider of industrial solutions, is proud to announce its latest breakthrough in the manufacturing of high-quality mill rolls. Our company, with over {number of years} years of experience in the industry, has always been at the forefront of innovation and continues to push boundaries to meet the evolving needs of our customers.With a strong commitment to technological advancements and a team of highly skilled engineers, we have developed a new line of mill rolls that are set to revolutionize the manufacturing processes in various industries. Our dedication to excellence and customer satisfaction has earned us a reputation as a trusted partner in the market.Our state-of-the-art manufacturing facility, equipped with the latest machinery and equipment, enables us to produce mill rolls with exceptional precision and performance. We employ rigorous quality control measures throughout the production process to ensure that each roll meets strict industry standards.[News Content]In a recent industry development, {Company Name} has unveiled its latest line of mill rolls, designed to enhance efficiency and productivity in the manufacturing sector. These mill rolls, which are available in various sizes and configurations, offer numerous benefits that are set to revolutionize the industry.One of the key features of our mill rolls is their superior durability and longevity. Made from high-quality materials, these rolls are designed to withstand heavy usage and maintain their performance over extended periods. This translates into reduced downtime and lower maintenance costs for our customers.Furthermore, our mill rolls are engineered to deliver exceptional precision and accuracy, resulting in high-quality finished products. The advanced manufacturing techniques employed in their production ensure consistent and uniform roll profiles, reducing variations in the output and enhancing overall product quality.With a focus on sustainability, our mill rolls are also designed to minimize material wastage during the manufacturing process. By optimizing the use of resources, we are able to reduce environmental impact while ensuring maximum efficiency and profitability for our customers.In addition to their superior performance, {Company Name}'s mill rolls are also highly versatile, suitable for use in a variety of industries. Whether it's the steel, aluminum, paper, or textile industry, our rolls are designed to meet the unique demands of each sector. This versatility makes them an ideal choice for manufacturers looking to streamline their operations and improve overall productivity.To provide exceptional customer support, {Company Name} offers comprehensive after-sales services, including installation, maintenance, and repair. Our team of experienced technicians is available round the clock to address any queries or concerns, ensuring uninterrupted operations for our valued customers.Since the announcement of our new line of mill rolls, industry experts have expressed their excitement about the potential impact that these rolls will have on the manufacturing sector. Professionals from various industries have acknowledged the innovative features and the potential for increased productivity and profitability.{Company Name} remains committed to driving innovation in the industry and providing cutting-edge solutions to our customers. Our latest line of mill rolls is a testament to this commitment and reinforces our position as a market leader in the industrial solutions sector.In conclusion, {Company Name} continues to pave the way for advancements in the manufacturing industry with the launch of its latest line of mill rolls. These rolls offer superior durability, precision, and versatility, empowering manufacturers to achieve higher levels of efficiency and productivity. With our unrivaled expertise and dedication to customer satisfaction, we are confident that our mill rolls will set new industry standards and drive success for our valued customers.

Understanding Cemented Carbide Dies and Their Applications in the Manufacturing Industry

In a recent development, a new addition to the cemented carbide die product line has been introduced by a leading carbide die manufacturer. The YG8 Cemented Carbide Die (name changed for confidentiality) has been designed keeping in mind the latest industry trends and customer needs. The product is expected to provide superior performance, durability, and cost-effectiveness.Cemented carbide, also known as tungsten carbide, is a composite material comprising a combination of tungsten carbide particles and a metallic binder. It is a popular material for the production of dies and cutting tools due to its high hardness, wear resistance, and toughness. Cemented carbide dies are used in a variety of industries, including metalworking, plastic processing, and automotive manufacturing.The YG8 Cemented Carbide Die is manufactured using advanced processes and techniques to ensure consistent quality and dimensional accuracy. It is made from high-quality tungsten carbide particles and a cobalt-based binder that provides excellent toughness and wear resistance. The die offers high hardness and strength, which makes it suitable for use in high-precision applications.The manufacturer has also implemented stringent quality control measures to ensure that the YG8 Cemented Carbide Die meets the highest industry standards. The product undergoes rigorous testing and inspection at every stage of the manufacturing process to ensure that it meets the required specifications. The company also offers customized solutions to meet specific customer requirements.The YG8 Cemented Carbide Die is suitable for use in a variety of applications, including wire drawing, cold heading, and forging. Its high wear resistance and toughness make it ideal for use in high-speed and heavy-duty applications. The die provides excellent dimensional stability and precision, which ensures consistent product quality and reduces the need for rework or scrap.The YG8 Cemented Carbide Die is also cost-effective, thanks to its long service life and low maintenance requirements. The advanced manufacturing processes used in its production ensure that it is durable and can withstand heavy use without losing its performance characteristics. Its low wear and tear also mean that it requires minimal maintenance, which reduces downtime and maintenance costs.The manufacturer of the YG8 Cemented Carbide Die is a leading carbide die manufacturer with decades of experience in the industry. The company is committed to providing high-quality products and services to its customers and has built a reputation for excellence in the industry. It employs a team of highly skilled professionals who use the latest technology and techniques to design and manufacture innovative products that meet the changing needs of customers.In addition to the YG8 Cemented Carbide Die, the company also offers a wide range of carbide dies and cutting tools for various applications. Its products are used by customers worldwide and its commitment to quality and customer service has earned it a loyal customer base.In conclusion, the YG8 Cemented Carbide Die is a high-quality product designed to provide superior performance, durability, and cost-effectiveness. Its advanced manufacturing processes, strict quality control measures, and customization options make it a suitable choice for a variety of applications and industries. As a leading carbide die manufacturer, the company is committed to providing innovative products and services that meet the changing needs of the industry and its customers.

How Cemented Carbide Drawing Dies are Made and Used

Cemented Carbide Drawing Die Proves to Be a Game-Changer in ManufacturingThe manufacturing industry has seen significant growth over the years, with new technologies constantly emerging in the market. One of the recent groundbreaking inventions in the industry is the Cemented Carbide Drawing Die - a product that has revolutionized the manufacturing of wires, tubes, and steel bars. This remarkable invention has shown to be a game-changer in the industry, offering manufacturers the ability to produce high-quality products efficiently and effectively.Cemented Carbide Drawing Die is a product made from a combination of tungsten carbide and cobalt. Through advanced engineering, technicians can create a mold that helps draw and shape a wide range of metals into the desired shape and size. Drawing is the process of reducing the diameter of metal rod or coiled wire by pulling them through a series of dies. The final product produced is usually used for different industrial applications.Cemented Carbide Drawing Die is an excellent example of how advanced engineering and technology can provide manufacturers with outstanding results. This innovative product boasts of several benefits, including efficiency, durability, strength, and high resistance to wear and tear. In addition, cemented carbide drawing dies make it possible for manufacturers to produce metal products that are perfectly shaped, with high precision and accuracy. This feature is crucial in ensuring the production of high-quality metal products.One of the companies that have embraced the use of cemented carbide drawing dies is the company (name removed). The company has been in operation for several years and has established itself as a leader in the manufacturing industry. The company prides itself on offering high-quality wire and tube drawing dies, rolls, and other metal forming tools.The use of cemented carbide drawing dies has enabled (name removed) to produce products that meet their clients' specific needs and requirements. The company's die manufacturing division uses advanced techniques and state-of-the-art equipment to produce high-quality products. By utilizing cutting-edge technologies, the company ensures that their dies carry out their function effectively and efficiently.Cemented carbide drawing dies have allowed (name removed) to reduce production cycle times, improve process efficiency and produce high-quality metal products. The quality of the final product produced is a result of the precision and accuracy of the cemented carbide drawing dies. The dies ensure that the wire and tube products produced by the company match the exact specifications given by the client.The high resistance to wear and tear of cemented carbide drawing dies ensures durability and reduces production costs. This quality makes it possible for (name removed) to produce products that outlast their competitors' products in the market.The cemented carbide drawing die also shows a significant improvement in terms of the shape and size of the final product produced. The dies give a high level of precision and accuracy, resulting in high-quality products.(Name removed) believes that the adoption of cemented carbide drawing dies has given them a competitive edge in the market. The product has enabled them to meet the high demands of their customers, produce high-quality products efficiently, and maintain cost-efficiency.The market for wire and tube drawing dies products is highly competitive, with many companies jostling for market share. In such a market, companies must adopt innovative and advanced technologies to gain a competitive edge. The cemented carbide drawing die is a product that has given (name removed) this edge and will continue to be a game-changer in the industry.In conclusion, the cemented carbide drawing die is one of the most significant innovations in the manufacturing world. Its efficiency, durability, strength, and high resistance to wear and tear make it an essential tool for the production of high-quality metal products. Companies that have adopted this product, such as (name removed), have been able to take advantage of the benefits that this product offers. Cemented carbide drawing dies will continue to transform the manufacturing industry, offering companies an opportunity to meet the high demands of their clients effectively.

High-Performance Tungsten Carbide Rolls: Unparalleled Strength and Durability

In the world of industrial manufacturing, there is a need for tools and machinery that can withstand the extreme pressure and wear associated with efficient production. One such tool that has gained popularity due to its durability is the tungsten carbide roll, a component used in steel rolling mills. Among the various brands available in the market, the YG8 tungsten carbide roll stands out for its quality and reliable performance.Manufactured by a leading tungsten carbide product supplier, the YG8 tungsten carbide roll is a high-density product that contains a combination of tungsten carbide and cobalt. This unique formulation provides the roll with exceptional hardness and strength, making it ideal for use in high-pressure rolling mills. The YG8 tungsten carbide roll is capable of withstanding severe wear and tear while maintaining precision and accuracy, making it an invaluable tool in the production process.One of the most significant advantages of using the YG8 tungsten carbide roll is that it has a longer lifespan than other types of rolling rolls. This extended lifespan translates into a lower cost of production, as it reduces the need for frequent replacement of the carbide roll. As a result, manufacturing companies can focus on increasing their productivity and revenue while maintaining high quality in their products.In addition to its exceptional quality and durability, the YG8 tungsten carbide roll also offers superior resistance to corrosion and oxidation. This makes it suitable for use in harsh environments, where moisture and chemical exposure can quickly damage other types of rolls. The roll's resistance to corrosion translates into a longer lifespan and an overall reduction in maintenance costs for manufacturing companies.The YG8 tungsten carbide roll is also known for its exceptional performance in high-temperature environments. The roll can withstand temperatures of up to 1000 degrees Celsius, making it ideal for use in hot rolling mills and other areas where high temperatures are prevalent. The roll's ability to handle extreme temperatures ensures that manufacturing companies can produce high-quality products efficiently and without any compromise in quality.Manufacturing companies that use the YG8 tungsten carbide roll can rest assured that they are using a product that has undergone strict quality control measures. The roll is tested and evaluated using advanced techniques to ensure that it meets the required standards for quality and durability. This rigorous testing process ensures that the YG8 tungsten carbide roll is reliable and can deliver consistent performance throughout its lifespan.The YG8 tungsten carbide roll has gained popularity among manufacturing companies in various industries due to its exceptional quality, durability, and performance. The roll's ability to withstand extreme wear and tear, high temperatures, and harsh environments makes it an essential tool in many production lines. With its extended lifespan and superior resistance to corrosion, the YG8 tungsten carbide roll is an excellent investment for manufacturing companies that prioritize efficiency and cost-effectiveness.In conclusion, the YG8 tungsten carbide roll is a reliable and superior quality product that offers exceptional durability and performance. Its unique formulation combining tungsten carbide and cobalt provides the roll with exceptional hardness and strength, making it suitable for use in high-pressure rolling mills. The roll's ability to withstand extreme temperatures, harsh environments, and resistance to corrosion makes it a valuable asset to manufacturing companies. As a tool that has undergone rigorous quality control measures, the YG8 tungsten carbide roll is an excellent investment for companies looking to increase productivity, efficiency, and reduce maintenance costs.

High-Quality Tungsten Carbide Pellet: A Versatile and Durable Material for Various Applications

Tungsten Carbide Pellet - The Future of Cutting ToolsTungsten carbide is a material that has been revolutionizing the field of cutting tools. Known for its exceptional hardness and wear resistance, tungsten carbide is used in a wide range of applications, from mining and drilling to manufacturing and construction. One company that has been at the forefront of this cutting-edge technology is {}. With their innovative tungsten carbide pellets, they have been setting new standards in the industry.Founded in {}, {} has been a leading manufacturer and supplier of tungsten carbide products for the past {} years. Their state-of-the-art production facilities and commitment to research and development have allowed them to consistently deliver high-quality products to their customers. They have built a solid reputation for providing innovative solutions for a variety of industries, including mining, construction, and metalworking.One of the key products that {} offers is their tungsten carbide pellets. These pellets are made from a mixture of tungsten and carbon powders, which are compressed and sintered at high temperatures to create a dense, hard, and wear-resistant material. The resulting pellets are then used to manufacture cutting tools, such as drills, end mills, and inserts, that are capable of withstanding the most demanding applications.The use of tungsten carbide in cutting tools offers several advantages over traditional materials. First and foremost, the hardness of tungsten carbide allows for higher cutting speeds and feeds, resulting in increased productivity and efficiency. Additionally, its exceptional wear resistance ensures a longer tool life, reducing the frequency of tool changes and associated downtime. This not only saves time and money but also increases the overall reliability of the cutting process.Furthermore, tungsten carbide has a high fracture toughness, making it less prone to chipping and breaking, even in the toughest machining conditions. This means that tools made from tungsten carbide can be used for a wider range of applications, and can handle more demanding cutting tasks without compromising performance or tool life.The team at {} is continuously working to improve their tungsten carbide pellets, conducting rigorous testing and analysis to ensure the highest quality and performance. They also collaborate closely with their customers to develop custom solutions that meet specific requirements and address unique challenges. This customer-centric approach has allowed {} to build strong, long-lasting relationships with their clients, who rely on them for cutting-edge products and technical expertise.In addition to their commitment to quality and innovation, {} is also dedicated to sustainability and environmental responsibility. They adhere to strict environmental standards in their manufacturing processes and continuously seek ways to minimize their impact on the environment. This includes investing in energy-efficient technologies, recycling materials, and reducing waste, all while maintaining the highest standards of product quality and performance.As the demand for high-performance cutting tools continues to grow, the importance of tungsten carbide in the manufacturing industry cannot be overstated. With its exceptional hardness, wear resistance, and toughness, tungsten carbide is poised to play a vital role in the future of cutting tool technology. Companies like {} are leading the way in developing and producing tungsten carbide products that push the boundaries of what is possible in the world of cutting tools.In conclusion, tungsten carbide pellets are at the forefront of cutting tool technology, offering unmatched performance and durability. With companies like {} leading the charge in innovation and quality, the future of cutting tools looks brighter than ever. As the manufacturing industry continues to evolve, tungsten carbide will undoubtedly remain a crucial material for meeting the demands of the modern world.

An In-Depth Guide on Tungsten Carbide Blanks: Uses, Properties, and Applications

Title: Leading Manufacturer Introduces High-Quality Tungsten Carbide BlanksIntroduction:In recent years, there has been a growing demand for high-performance tools and components across various industries. To meet this demand, global manufacturing leader {Company Name} has introduced its latest offering: a range of precision-engineered Tungsten Carbide Blanks. These blanks are specifically designed to provide exceptional strength, durability, and wear resistance, making them an ideal choice for industrial tooling applications.I. Overview of Tungsten Carbide:Tungsten Carbide is a compound composed of tungsten metal and carbon atoms. Renowned for its incredible hardness and toughness, it is widely considered one of the hardest materials known to man. Due to this exceptional strength, Tungsten Carbide has become a favored choice for tools and components in demanding environments such as aerospace, automotive, mining, and precision machining.II. Unrivaled Durability and Wear Resistance:{Company Name}'s Tungsten Carbide Blanks offer unparalleled durability and wear resistance, ensuring a longer tool life and reduced downtime. The exceptional hardness of Tungsten Carbide results in superior resistance to abrasion, impact, and high temperatures, making it less prone to wear and providing a high level of overall performance.III. Precision Engineering:The Tungsten Carbide Blanks manufactured by {Company Name} are meticulously engineered to meet the highest industry standards. Following a stringent quality control process, each blank is precisely ground, shaped, and polished to achieve optimal dimensional accuracy and surface finish. This attention to detail ensures that the blanks are ready to be further processed and customized according to specific tooling requirements.IV. Diverse Applications:The versatility of Tungsten Carbide Blanks allows them to be utilized in a wide range of applications. With their exceptional strength and durability, these blanks are extensively used in the production of drill bits, cutting tools, inserts, dies, punches, and wear parts for various industries. This adaptability, combined with their superior performance, enhances the overall productivity and efficiency of manufacturing processes.V. Customer-Centric Approach:{Company Name} takes pride in its customer-centric approach, understanding the unique requirements of different industries and providing tailored solutions. The company's dedicated research and development team works closely with customers to develop customized Tungsten Carbide Blanks that address specific application challenges. This collaborative approach ensures that the resulting blanks meet the precise needs of the end-users, enabling them to achieve optimal performance and meet their production goals.VI. Commitment to Sustainability:In addition to technical excellence, {Company Name} remains committed to sustainability. The Tungsten Carbide Blanks manufactured by the company are produced using environmentally-friendly processes, reducing energy consumption and minimizing waste. By prioritizing sustainable practices, {Company Name} contributes to a greener future while manufacturing top-quality products.VII. Conclusion:As industries continue to evolve, the demand for high-performance tools and components remains constant. With the introduction of its premium Tungsten Carbide Blanks, {Company Name} reaffirms its commitment to meeting this demand and providing exceptional products to its customers globally. Through a combination of precision engineering, resilience, and sustainability, these blanks are set to revolutionize the manufacturing landscape, enabling industries to reach new heights of productivity and efficiency.