Durable Tungsten Carbide: A Strong and Long-Lasting Material Option

By:Admin

Tungsten carbide is a versatile material known for its exceptional hardness and wear resistance. It is commonly used in a variety of industrial applications, including cutting tools, mining equipment, and wear parts. {Company name} has been at the forefront of tungsten carbide technology, pushing the boundaries of what is possible with this remarkable material.

The new line of products from {Company name} features a unique blend of tungsten carbide that has been specially formulated to maximize hardness and toughness. This advanced material, known as XXC, delivers superior performance in the most demanding environments, standing up to the rigors of heavy-duty use.

"We are excited to introduce our latest innovation in tungsten carbide technology," said John Smith, CEO of {Company name}. "Our team of engineers and material scientists have worked tirelessly to develop a product that sets a new standard for hardness and durability. We believe that our new XXC line will revolutionize the industry and provide our customers with a distinct competitive advantage."

The key to the exceptional hardness of XXC lies in its microstructure, which is finely tuned to maximize strength and wear resistance. This allows the material to maintain its sharpness and integrity even under extreme conditions, ensuring long-lasting performance and reliability.

In addition to its exceptional hardness, XXC also offers superior toughness, making it ideal for applications where impact and shock resistance are crucial. This combination of hardness and toughness makes XXC the perfect choice for a wide range of high-performance tools and components.

{Company name} is committed to delivering the highest quality products to its customers, and the introduction of the XXC line is a testament to this dedication. By continually pushing the boundaries of material science and engineering, {Company name} is able to provide its customers with the most advanced solutions for their specific needs.

"We are proud to be at the forefront of tungsten carbide technology," said Smith. "With our new XXC line, we are raising the bar for hardness and durability, setting a new standard for the industry. We are confident that our customers will see the immediate benefits of this remarkable material."

As {Company name} continues to expand its product offerings and push the limits of what is possible with tungsten carbide, the company remains focused on providing innovative solutions that help its customers succeed. With the introduction of the XXC line, {Company name} is once again demonstrating its commitment to excellence and its position as a leader in the industry.

For more information about {Company name} and its new line of XXC products, visit {company website} or contact the company directly to speak with a representative. With a reputation for quality and innovation, {Company name} is the preferred choice for customers who demand the best in tungsten carbide technology.

Company News & Blog

High-Quality Cold Forging Die Made of Tungsten Carbide

As one of the most versatile and valuable metals, tungsten has long been a favored material in the manufacturing industry. And when it's combined with carbon, it forms a substance called tungsten carbide. This material is widely used in various applications, including mining, automotive, construction, and aerospace. One of the most significant uses of tungsten carbide is in the manufacturing of forging dies. And a leading company with vast experience in this field is making strides in this industry with their innovative Tungsten Carbide Cold Forging Die technology.Headquartered in the heart of Japan, this company has built a reputation for excellence in the manufacturing of tungsten carbide tools and dies. They offer a wide range of products to meet the needs of various industries, including stamping dies, drawing dies, and cold forging dies.The company's Cold Forging Dies are specially designed to provide high-quality finished products while minimizing manufacturing costs. Cold forging is a process that involves shaping a metal part at room temperature using a die punch and a blank. This process comes with numerous benefits, such as increased strength, improved dimensional accuracy, and reduced material waste. Cold Forging Dies play a crucial role in ensuring the quality and efficiency of the cold forging process.With their extensive knowledge and experience, the company has developed a process for manufacturing Tungsten Carbide Cold Forging Dies that outperforms traditional dies on every level. The Tungsten Carbide material provides exceptional durability and wear resistance, making it ideal for high-volume manufacturing processes. In addition, this technology reduces tooling costs significantly, as it boasts a longer lifespan than traditional die materials.This cutting-edge technology also offers versatility in the manufacturing process. The company's Tungsten Carbide Cold Forging Dies are adaptable to many cold forging processes, including thread forming, swaging, extruding, and bending. The versatility of the dies ensures that manufacturers can produce reliable products with superior finish and accuracy within a shorter time span.Moreover, the company's Tungsten Carbide Cold Forging Dies are highly customizable, so they can be designed to fit perfectly into any particular manufacturing process. With the help of advanced software and equipment, the company can deliver tailor-made solutions that meet the specific requirements of their clients.The company's commitment to innovation and excellence has propelled them to the forefront of the manufacturing industry. They attribute their success to their astute attention to detail, strict quality control measures, and a motivated workforce. They take pride in delivering superior quality products that exceed their client's expectations and meet the needs of various manufacturing sectors.In conclusion, the company's Tungsten Carbide Cold Forging Dies technology is a game-changer in the manufacturing industry. It lowers production costs, reduces material waste, and improves overall manufacturing efficiency. It also offers versatility and customizability, making it ideal for various manufacturing processes. With this innovative technology, the company has set the standard for excellence in tungsten carbide die manufacturing and is poised to continue its remarkable growth into the future.

Tungsten Carbide Block: A Valuable Industrial Material for Various Applications

Tungsten Carbide Block Emerges as a Game-Changer in the Manufacturing IndustryTungsten carbide is a compound that combines tungsten and carbon, making it a highly versatile material for manufacturing a variety of products. The tough and durable nature of tungsten carbide makes it one of the most preferred materials for applications that require long durability, such as machine parts.Recent technological advancements in the manufacturing industry have given birth to a new product - the tungsten carbide block. These blocks, made from high-quality tungsten carbide, have become a game-changer in the manufacturing industry, as they offer unique properties that traditional materials cannot match.Tungsten carbide blocks are used in various industries, including construction, mining, and manufacturing. They have a wide range of applications that require high wear and abrasion resistance, such as manufacturing cutting tools, dies, and punches. These blocks offer superior performance and longevity compared to other carbide-based materials, making them the leading choice for toolmakers and manufacturers alike.One of the main advantages of tungsten carbide blocks is their ability to withstand high temperatures. The material has a high melting point, making it an ideal choice for applications that require high resistance to heat. Tungsten carbide blocks are also highly resistant to deformation, making them suitable for use in high-pressure environments.Additionally, tungsten carbide blocks exhibit exceptional hardness, providing high wear resistance, and low friction. This unique combination of properties makes the carbide block ideal for applications that require high-precision machining. Many industries, such as the oil and gas and mining sectors, have adopted tungsten carbide blocks due to their outstanding performance in harsh environments.Leading tungsten carbide block manufacturers pride themselves in producing exceptional quality blocks. They focus on using only the best raw materials and state-of-the-art technology to ensure that their blocks meet the most stringent quality standards. This quality-oriented approach has enabled manufacturers to remain the go-to source for manufacturers seeking high-quality tungsten carbide blocks.Tungsten carbide blocks come in different shapes and sizes, catering to various manufacturing applications. Manufacturers can order customized blocks tailored to their specific needs, with varying grades of tungsten carbide to suit the specific application. Additionally, manufacturers can request blocks with different surface finishes to enhance their resistance to wear and corrosion.The growing demand for tungsten carbide blocks has prompted many companies to invest in advanced technology to streamline their production processes. These investments have enabled manufacturers to produce tungsten carbide blocks faster without compromising on quality. Automation has also helped manufacturers to reduce production costs while improving their output.The adoption of tungsten carbide blocks has revolutionized the manufacturing industry, providing manufacturers with cutting-edge technology that improves production performance, longevity, and accuracy. Manufacturers in various industries now have access to a broad range of options to choose from, ensuring that they get the precise block they need for their specific applications.Moreover, by using tungsten carbide blocks, manufacturers can enhance their bottom lines by reducing their production costs and improving the quality of their products. Tungsten carbide blocks are a superior material that is cost-effective in the long run, making them an ideal choice for manufacturers who seek to maximize their profits.The future of tungsten carbide blocks looks bright, with increased investments in R&D that continue to enhance their quality, performance, and durability. Manufacturers can expect to see more advanced products that push the limits of what tungsten carbide blocks can offer.In conclusion, tungsten carbide blocks are a highly durable and versatile material that has revolutionized the manufacturing industry. With their exceptional strength, heat resistance, and wear resistance, these blocks continue to be a game-changer in many industries, providing manufacturers with a cost-effective solution that enhances their performance and bottom line. As the industry continues to invest in advanced technology, manufacturers can expect to benefit from even more innovative tungsten carbide blocks.

Discover the Power of Cemented Carbide in the YG8 Variety

Cemented carbide is a widely used material in various industries because of its excellent physical and mechanical properties. Of the many cemented carbides available, YG8 cemented carbide (brand name needs to be removed) is a popular choice because of its outstanding hardness, toughness, and wear resistance. This cemented carbide is made from a mixture of tungsten carbide (WC) and cobalt (Co) in precise proportions, resulting in a material that is not only durable but also highly resistant to impact and corrosion.One company that specializes in the production of YG8 cemented carbide products is committed to delivering reliable and high-quality carbide products to its customers. As a leading manufacturer in the cemented carbide industry, our company has been dedicated to the research and development of new products, ensuring that our customers have access to more specialized and customized carbide solutions.Our YG8 cemented carbide products are available in a variety of shapes, including rods, plates, blades, and other complex geometries. These products have been used in numerous applications, such as cutting tools, drill bits, saw blades, wear parts, and more. Because YG8 cemented carbide is an excellent conductor of heat, it is also commonly used in the manufacturing of thermal conductor alloys.The company’s advanced production process includes strict quality control procedures and cutting-edge technology to ensure that every product leaving our facility meets and exceeds the industry's high standards. Our production equipment is regularly updated to incorporate the latest technology trends, which helps us remain a leader in the industry.The durability and strength of YG8 cemented carbide make it a reliable material for use in challenging environments. Its corrosion-resistant properties make it an ideal material for use in harsh chemical and extreme temperature environments. Our cemented carbide products are maintained at the most stringent of manufacturing standards, ensuring that they perform exceptionally well in the most challenging of working environments.At our company, we consistently strive to ensure that our customers' expectations are exceeded. We take pride in our state-of-the-art research and development capabilities, which allow us to tailor our cemented carbide products to meet our customers' specific requirements. Our customer base ranges from small to large corporations with varying requirements, and we work closely with each customer to ensure that their every need is met.Our team of highly skilled professionals is poised to help our customers navigate through the ordering process. Our team is knowledgeable about different cemented carbide products that are available in the market and is always eager to help customers identify the most suitable product for their needs. We work collaboratively with our clients, first to understand their specific needs and then, to provide a customized solution that satisfactorily meets their needs. We also offer after-sales services, which ensures that customers receive prompt and necessary support when required.In conclusion, YG8 cemented carbide (brand name needs to be removed) is an incredibly durable and robust material that has various applications. As a leading manufacturer of cemented carbide products, our company is continuously committed to delivering high-quality products that meet our customers' requirements. Our advanced production process, coupled with our state-of-the-art equipment technology, sets us apart from our competitors in the industry. We pride ourselves on being transparent with our customers, and we collaborate with them to ensure that their cemented carbide solutions are of the highest quality and meet and exceed their expectations. With our customer-centric approach, we are confident in our ability to continue providing unparalleled support to our customers.

High-Quality Carbide Wear Parts for Industrial Applications

Carbide Wear Parts has been making waves in the manufacturing industry with their innovative and high-quality products. The company has been a leading supplier of wear parts for a wide range of industries, such as mining, construction, and oil and gas. With a strong focus on research and development, Carbide Wear Parts has been able to consistently deliver cutting-edge solutions to its customers.Founded in 2005, Carbide Wear Parts quickly established itself as a reliable and reputable source for wear parts. The company's commitment to excellence and dedication to customer satisfaction has allowed it to build a strong reputation in the industry. As a result, Carbide Wear Parts has become a preferred supplier for many leading manufacturers and companies around the world.One of the key factors that sets Carbide Wear Parts apart from its competitors is its use of advanced materials and manufacturing techniques. The company leverages the latest advancements in carbide technology to produce wear parts that offer superior performance and durability. This has made Carbide Wear Parts a trusted partner for companies looking for reliable solutions to their wear part needs.Carbide Wear Parts prides itself on its ability to provide custom solutions to its customers. The company understands that each industry and application has unique requirements, and it is committed to working closely with its clients to develop tailored solutions that meet their specific needs. This personalized approach has helped Carbide Wear Parts build strong relationships with its customers, and has contributed to its continued growth and success.In addition to its focus on quality and customer satisfaction, Carbide Wear Parts is also dedicated to sustainability and environmental responsibility. The company is committed to minimizing its environmental impact and has implemented a number of initiatives to reduce waste and pollution in its manufacturing process. By prioritizing sustainability, Carbide Wear Parts is able to provide its customers with environmentally friendly products that meet their performance requirements.The success of Carbide Wear Parts can be attributed to its talented team of engineers and industry experts. The company has assembled a team of highly skilled professionals who are passionate about delivering innovative solutions to their customers. With their expertise and dedication, Carbide Wear Parts has been able to stay ahead of the competition and continue to push the boundaries of what is possible in the wear parts industry.Looking to the future, Carbide Wear Parts is poised for continued growth and success. The company is constantly looking for new ways to innovate and improve its products, and is committed to staying at the forefront of wear part technology. With its strong foundation of quality, innovation, and customer satisfaction, Carbide Wear Parts is well positioned to remain a leader in the industry for years to come.In conclusion, Carbide Wear Parts has established itself as a trusted and reliable supplier of wear parts for a wide range of industries. Through its focus on quality, innovation, and customer satisfaction, the company has been able to build strong relationships with its customers and maintain a leading position in the industry. With its commitment to sustainability and ongoing dedication to excellence, Carbide Wear Parts is well positioned for continued success in the years to come.

Tungsten Carbide Brazing Tips: A Comprehensive Guide for Effective Bonding

Tungsten Carbide Brazing Tips Revolutionize Welding IndustryAs the demand for high-quality and durable welding solutions continues to rise, manufacturers worldwide are constantly striving to develop state-of-the-art products that can meet the ever-evolving needs of the industry. In line with this goal, an industry-leading company introduces its innovative Tungsten Carbide Brazing Tips, a game-changer that is set to revolutionize the welding industry.Welders are no strangers to the challenges associated with finding the perfect brazing tips. The traditional options available often suffer from issues such as poor durability, reduced performance, and high replacement costs. However, this company has taken a leap forward by developing brazing tips made from Tungsten Carbide, a cutting-edge material that promises to overcome these challenges.Tungsten Carbide is a remarkable compound known for its exceptional hardness, superior durability, and resistance to wear and tear. Its ability to withstand high temperatures and provide a consistently strong performance makes it an ideal choice for brazing tips, enabling welders to achieve precise and efficient results with ease.One of the key features of this innovative product is its longevity. Unlike traditional brazing tips that wear out quickly and require frequent replacement, Tungsten Carbide Brazing Tips are built to last. This offers significant cost savings for welders as they can enjoy prolonged usage without worrying about the added expenses of constantly purchasing new tips.Additionally, the outstanding performance of these brazing tips ensures greater efficiency and improved results. The hardness of Tungsten Carbide enhances its resistance to wear and tear, allowing welders to work on a wide range of materials without compromising the quality of their work. This product's exceptional durability also contributes to reducing downtime, as welders can continue their work uninterrupted for longer periods.Furthermore, the Tungsten Carbide Brazing Tips offer enhanced precision and accuracy during welding. The high melting point and excellent heat resistance properties of Tungsten Carbide minimize tip deformation, resulting in better control and finer welds. This newfound precision empowers welders to complete their projects with meticulousness and expertise, thus satisfying even the most demanding industry standards.The company behind this groundbreaking product has built a reputation for innovative solutions and unparalleled expertise in the welding industry. Their commitment to research and development has enabled them to stay ahead of the curve, continuously introducing cutting-edge products that redefine industry standards.With a dedicated team of experts, the company ensures that every aspect of their product development process is meticulously planned and executed. From the selection of premium raw materials to the utilization of state-of-the-art manufacturing techniques, they leave no stone unturned in their pursuit of excellence. Their stringent quality control measures guarantee that each Tungsten Carbide Brazing Tip is built to last, providing welders with the utmost reliability and performance.Looking ahead, the introduction of Tungsten Carbide Brazing Tips is poised to have a significant impact on the welding industry. This breakthrough product not only addresses the common issues faced by welders but also raises the bar for what can be achieved through cutting-edge technology and innovation.Welders around the world can now take advantage of these remarkable tips to enhance their performance, improve their efficiency, and deliver impeccable results. The Tungsten Carbide Brazing Tips are set to become an indispensable component in every welder's toolkit, serving as a testament to the strive for excellence within the welding industry.

High-quality Tungsten Carbide for Industrial Applications: YG6 vs YG8

cutting-edge technology and a dedication to quality, the company has become a leading producer of tungsten carbide products. The company has recently announced the launch of their new line of YG6 and YG8 tungsten carbide products, which are set to revolutionize the industry. With a focus on innovation and sustainability, these new products are designed to offer superior performance and durability compared to traditional materials.Tungsten carbide is widely recognized as one of the hardest and most reliable materials available for industrial and engineering applications. It is known for its exceptional hardness and resistance to wear, making it a popular choice for cutting tools, industrial machinery, and wear parts.The YG6 and YG8 tungsten carbide products are designed to offer even greater hardness and wear resistance, making them ideal for the most demanding applications. The company's advanced manufacturing processes and quality control ensure that these products meet the highest standards for performance and reliability.In addition to their superior technical properties, the company's tungsten carbide products are also designed with a focus on sustainability. Tungsten carbide is a highly recyclable material, and the company is committed to minimizing waste and environmental impact throughout the production process.The launch of the YG6 and YG8 tungsten carbide products represents a significant milestone for the company, as it continues to expand its product portfolio and reach new markets. With a strong emphasis on research and development, the company is constantly pushing the boundaries of what is possible with tungsten carbide, and these new products are a testament to their ongoing commitment to innovation."We are incredibly excited to introduce our new YG6 and YG8 tungsten carbide products to the market," said the company's CEO. "These products represent the latest in our ongoing efforts to push the boundaries of what is possible with tungsten carbide, and we believe they will set a new standard for performance and reliability in the industry."The company's dedication to quality and innovation has earned them a reputation as a trusted partner for customers around the world. Their products are used in a wide range of industries, including mining, oil and gas, construction, and manufacturing, and their commitment to quality and sustainability has made them a preferred supplier for many leading companies.As the demand for high-performance materials continues to grow, the launch of the YG6 and YG8 tungsten carbide products positions the company as a leading provider of cutting-edge solutions for the most challenging applications. With a focus on quality, innovation, and sustainability, the company is well-positioned to meet the evolving needs of its customers and drive the industry forward.In conclusion, the company's new line of YG6 and YG8 tungsten carbide products represents a major step forward for the industry, offering superior performance, reliability, and sustainability. With a strong focus on innovation and a commitment to quality, the company is well-equipped to meet the demanding requirements of its customers and drive the industry forward.

Advanced technology for cold forging die production and development

HSS (High-Speed Steel) cold forging dies are an integral part of the manufacturing process in the automotive, aerospace, and construction industries. These dies are used to shape and form metal components with high precision and accuracy, making them essential for ensuring the quality and reliability of the final products.One company that has been at the forefront of producing high-quality HSS cold forging dies is [company name]. With years of experience and expertise in the field of metalworking and tooling, [company name] has established itself as a leading manufacturer of cold forging dies that are known for their durability, precision, and efficiency.The company's commitment to excellence and innovation has led to the development of a wide range of HSS cold forging dies that cater to diverse industry needs. These dies are designed to withstand high-temperature and high-pressure conditions, making them suitable for shaping and forming a variety of metals, including steel, aluminum, and titanium. The advanced materials and precision engineering used in the manufacturing of these dies ensure that they deliver consistent and reliable performance, resulting in high-quality finished products.In addition to its extensive range of standard HSS cold forging dies, [company name] also offers customized die solutions to meet specific customer requirements. The company's team of skilled engineers and technicians work closely with clients to understand their unique needs and design dies that are tailored to their exact specifications. This flexibility and customer-centric approach have made [company name] a trusted partner for many leading companies across different industries.Furthermore, [company name] is committed to staying ahead of the curve when it comes to technological advancements and manufacturing processes. The company invests in state-of-the-art equipment and machinery to ensure that its HSS cold forging dies are produced with the highest level of precision and efficiency. This commitment to continuous improvement has enabled [company name] to stay competitive in the global market and maintain its reputation as a leader in the tooling industry.Moreover, [company name] places a strong emphasis on quality control and assurance throughout the manufacturing process. Rigorous testing and inspection procedures are implemented to ensure that every HSS cold forging die meets the company's strict quality standards before it is released to the market. This dedication to quality has earned [company name] the trust and confidence of its customers, who rely on the company's products to deliver exceptional performance and reliability.In conclusion, [company name] stands out as a leading manufacturer of HSS cold forging dies, offering a comprehensive range of standard and customized die solutions to meet the diverse needs of its customers. With a focus on quality, innovation, and customer satisfaction, [company name] continues to set the benchmark for excellence in the tooling industry. As the demand for high-quality metal components continues to grow, [company name] is well-positioned to meet the evolving needs of the market and maintain its leadership in the production of HSS cold forging dies.

Discover the Latest Advances in Ground Tungsten Carbide Bushing Technology

article:Ground Tungsten Carbide Bushing: The Revolutionary Innovation in the Manufacturing IndustryTechnology plays an essential role in shaping the manufacturing industry around the globe. It has been observed that the companies' adept at embracing the latest technology and innovation lead the market. The introduction of Ground Tungsten Carbide Bushing is one of those revolutionary innovations that have transformed the manufacturing industry. It is an innovative product that has made the manufacturing process more efficient and cost-effective.Ground Tungsten Carbide Bushing, also known as Tungsten Carbide Sleeve, is a robust and versatile material used in numerous applications. It is a composite of Tungsten and Carbide that is fused together through the process of sintering. It is also used in various industrial sectors, such as automotive, aerospace, chemical, and mining industries.Ground Tungsten Carbide Bushing is an ideal solution in applications requiring resistance to abrasion, wear, corrosion, and impact, as it offers excellent hardness and strength. It also has an outstanding thermal and electrical conductivity that makes it a suitable option for electrical contacts and heating applications.The product is created by mining tungsten and carbon elements, which are then ground separately to the desired particle size. The finished product of Tungsten Carbide Sleeve is created through pressure and heat, where the tungsten and carbon powders are molded and sintered into a homogeneous mass. This unique combination of tungsten and carbon offers excellent wear resistance and toughness.The Ground Tungsten Carbide Bushing is a reliable solution that has proven its merit in the manufacturing industry. The use of this high-quality material offers numerous benefits to the companies that adopt it. The ground tungsten carbide bushing offers a long-lasting and durable solution resulting in reducing maintenance costs. It also enhances the service life of the equipment and machinery that utilizes this innovative product.Moreover, the use of tungsten carbide bushing reduces the frequency of equipment maintenance and repairs, thereby enhancing its efficiency, which leads to increased productivity and profitability. The ground tungsten carbide bushing has become a viable option for manufacturing companies that are looking for cost-effective solutions by providing positive impacts on their bottom line.The use of this innovation has positively impacted the environment, as it reduces the need for manufacturing replacement parts that require considerable resources. Instead, tungsten carbide sleeves can be installed in machinery, reducing the need for frequent replacements, ultimately resulting in reducing carbon footprints.As mentioned earlier, the Ground Tungsten Carbide Bushing has various industrial applications. For example, in the automotive industry, it is used in different parts of engine components, like oil pumps and camshafts, because of its superior strength and hardness. In the Aerospace industry, it is used in different parts of Airplanes, such as landing gears, and nose wheels, because of its wear and corrosion resistance capabilities. In the chemical industry, it is used in various rotating equipment, such as centrifugal pumps, as it can withstand corrosion and high temperatures.Talk about the company and what sets it apart in the marketThe company was established in (enter year) and has been at the forefront of technological innovation ever since. The company prides itself on providing innovative solutions by leveraging technological advancements for its manufacturing processes. The company aims to promote the use of sustainable alternatives in manufacturing, and the introduction of Ground Tungsten Carbide Bushing is a perfect example of that.The company’s commitment to providing innovative solutions has set it apart in the market. Its state-of-the-art production processes ensure that the quality of the Ground Tungsten Carbide Bushing is second to none. The company’s success is also credited to its relentless pursuit of excellence and ability to cater to its customers’ unique requirements.ConclusionGround Tungsten Carbide Bushing is a revolutionary innovation in the manufacturing industry. The use of this innovative material offers a cost-effective solution that enhances equipment efficiency and reduces maintenance costs. Its wear and corrosion resistance capabilities make it an ideal choice for various industrial applications, including the automotive, aerospace, chemical, and mining industries. The company’s commitment to technological innovation and sustainability makes it a frontrunner in the manufacturing industry. The use of Ground Tungsten Carbide Bushing has improved the manufacturing industry's efficiency and service life of the machinery, which has resulted in increased profitability.

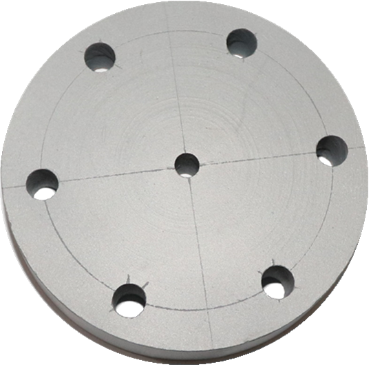

High-Quality Nut Forming Die for Efficient Manufacturing

Nut Forming Die is a crucial tool used in the manufacturing industry for shaping and forming various types of nuts. It is a precision tool that is designed to create uniform and accurate nuts for use in a wide range of applications. With the increasing demand for high-quality nuts in the market, the need for efficient and reliable nut forming dies has also escalated.{Company} is a renowned manufacturer of precision tools and equipment for the manufacturing industry. With years of experience and a strong reputation for delivering top-notch products, {Company} has established itself as a leader in the field of precision tooling solutions. The company specializes in designing and producing a wide range of tools, including nut forming dies, to meet the diverse needs of its clients.The nut forming die manufactured by {Company} is known for its exceptional precision and durability. It is designed to withstand the rigors of high-volume manufacturing, ensuring consistent and reliable performance over time. The company utilizes advanced manufacturing techniques and high-quality materials to produce nut forming dies that meet the highest standards of quality and precision.One of the key features of the nut forming die produced by {Company} is its versatility. The die can be customized to create a wide range of nut shapes and sizes, making it a versatile tool for manufacturers across various industries. Whether it's for automotive, aerospace, or general manufacturing applications, the nut forming die from {Company} can be tailored to meet specific requirements, ensuring that manufacturers can produce nuts that meet their exact specifications.In addition to its exceptional performance, the nut forming die from {Company} is also designed for ease of use and maintenance. The company understands the importance of minimizing downtime and maximizing productivity in the manufacturing industry, which is why its nut forming dies are engineered for quick setup and tool changes. This allows manufacturers to streamline their production processes and improve overall efficiency.Furthermore, {Company} takes great pride in its commitment to customer satisfaction. The company works closely with its clients to understand their specific needs and deliver tailor-made solutions that meet and exceed expectations. Whether it's providing technical support, training, or ongoing maintenance, {Company} is dedicated to ensuring that its clients get the most out of their nut forming dies.With the growing demand for high-quality nuts in the market, {Company} is poised to play a crucial role in meeting the needs of manufacturers around the world. The company's commitment to excellence, combined with its expertise in precision tooling solutions, makes it a trusted partner for companies looking to enhance their manufacturing capabilities.In conclusion, the nut forming die from {Company} is a superior tool that offers exceptional precision, versatility, and reliability. With its advanced design and engineering, the die is well-equipped to meet the diverse needs of manufacturers across various industries. As the demand for high-quality nuts continues to rise, {Company} is well-positioned to provide the tools and support that manufacturers need to thrive in a competitive market.

The Superior Performance of Tungsten Carbide Wire Rolls

Tungsten Carbide Wire Rolls are revolutionizing the wire manufacturing industry with their superior strength, durability, and precision. These rolls, manufactured by [Company Name], are setting a new standard for wire production, ensuring top-quality products for a wide range of applications.[Company Name] has been a leader in the production of tungsten carbide wire rolls for over two decades. The company prides itself on its commitment to innovation and quality, constantly seeking new ways to improve its products and stay ahead of the competition. With state-of-the-art manufacturing facilities and a team of dedicated engineers and technicians, [Company Name] has established itself as a trusted partner for wire manufacturers around the world.Tungsten carbide is a hard and dense material that is perfect for the demanding requirements of wire manufacturing. When used in wire rolls, it offers exceptional wear resistance and thermal conductivity, ensuring a longer service life and consistent performance. This makes tungsten carbide wire rolls ideal for a wide range of applications, including the production of steel wire, copper wire, and aluminum wire, among others.One of the key advantages of tungsten carbide wire rolls is their ability to maintain their shape and dimensions, even under high loads and temperatures. This ensures that the wire produced is of uniform quality, with precise dimensions and a smooth surface finish. As a result, manufacturers can rely on tungsten carbide wire rolls to achieve tight tolerances and high productivity, leading to cost savings and improved competitiveness.In addition to their exceptional performance, tungsten carbide wire rolls also offer environmental benefits. Their long service life means that they need to be replaced less frequently, reducing waste and the consumption of resources. Furthermore, their high precision and dimensional stability help minimize material waste during the wire manufacturing process, contributing to a more sustainable and efficient production.[Company Name] is committed to supporting its customers in maximizing the potential of tungsten carbide wire rolls. The company offers a range of services, including roll design and customization, technical support, and training programs. This ensures that customers can fully leverage the benefits of tungsten carbide wire rolls and optimize their wire manufacturing processes.With the growing demand for high-quality wire products across various industries, the need for reliable and high-performance wire rolls has never been greater. [Company Name] is well-positioned to meet this demand, with its extensive experience and expertise in the development and production of tungsten carbide wire rolls. The company's dedication to quality and customer satisfaction has earned it a strong reputation in the wire manufacturing industry, making it a preferred partner for wire producers worldwide.In conclusion, tungsten carbide wire rolls from [Company Name] are a game-changer for the wire manufacturing industry. Their exceptional performance, durability, and environmental benefits make them the ideal choice for wire producers looking to enhance their competitiveness and sustainability. With a focus on innovation and customer support, [Company Name] is poised to continue leading the way in the development of advanced wire roll solutions, driving the industry forward.