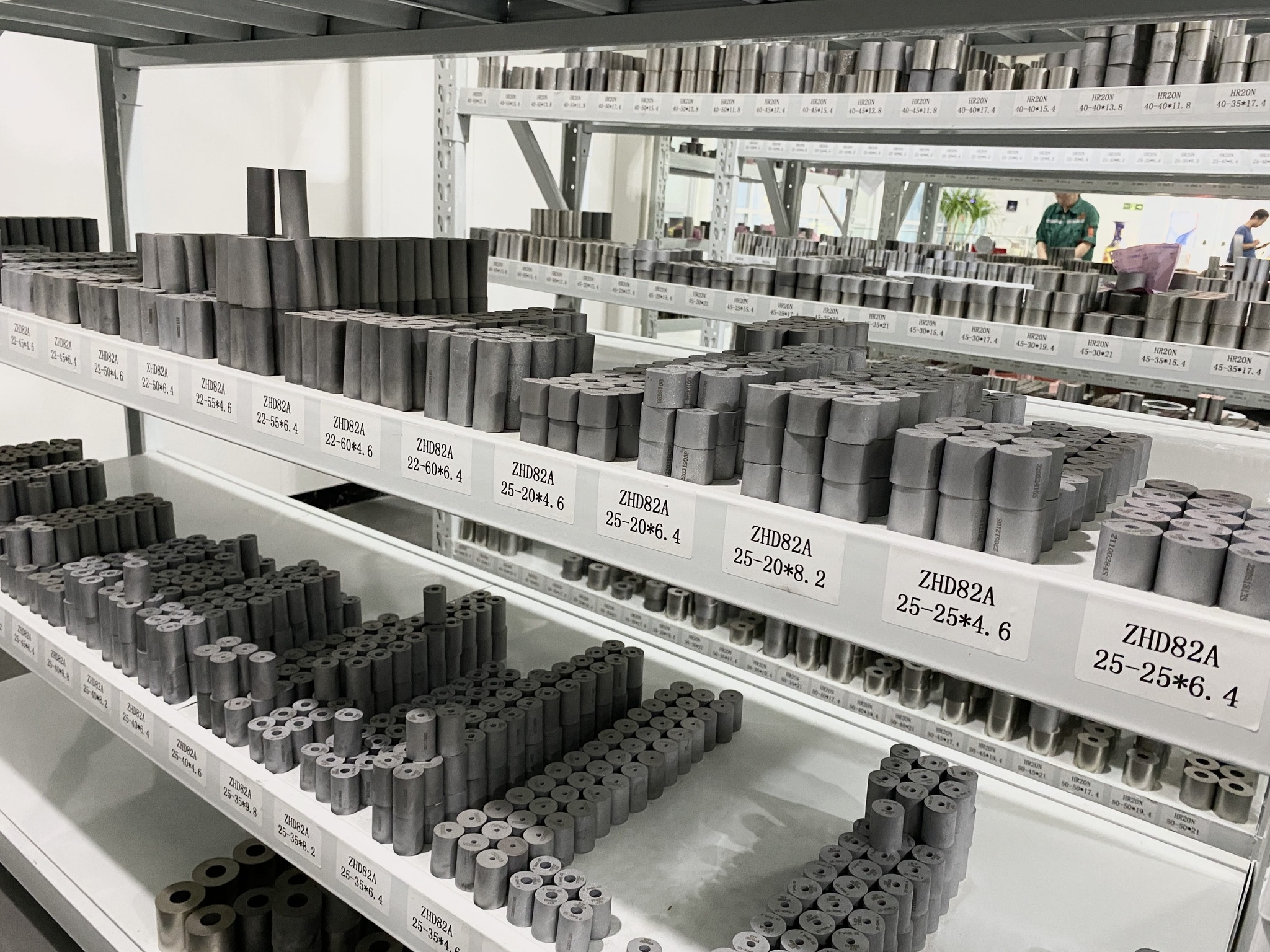

Durable Tungsten Carbide Bushings for Industrial Applications

By:Admin

{City, Date} - {Company Name}, a leading manufacturer of industrial equipment, has recently announced the implementation of Tungsten Carbide Bushing in their products. The use of this advanced material is expected to enhance the performance and durability of their equipment, further solidifying their reputation for high quality and reliability.

Tungsten Carbide is a highly durable and heat-resistant material that is commonly used in industrial applications. It is known for its exceptional hardness and wear resistance, making it an ideal choice for components that are subjected to extreme conditions. By incorporating Tungsten Carbide Bushing into their products, {Company Name} aims to ensure that their equipment can withstand the rigors of heavy-duty use in various industrial settings.

{Company Name} has earned a strong reputation in the industry for its commitment to quality and innovation. With a focus on continuous improvement, the company is dedicated to staying ahead of the curve by adopting the latest technologies and materials. The decision to integrate Tungsten Carbide Bushing into their product line is a reflection of their dedication to delivering top-of-the-line equipment that meets the evolving needs of their customers.

In addition to enhancing the performance and longevity of their products, the use of Tungsten Carbide Bushing also enables {Company Name} to offer equipment that requires minimal maintenance. This can translate to cost savings for their customers, as they can rely on the durability of the equipment without having to invest significant resources in upkeep and repairs.

Furthermore, the implementation of Tungsten Carbide Bushing demonstrates {Company Name}'s commitment to sustainability. By producing equipment that boasts a longer lifespan and reduced maintenance requirements, the company is contributing to a more environmentally friendly approach to industrial operations. This aligns with {Company Name}'s values of corporate responsibility and environmental stewardship, as they strive to minimize their impact on the planet while providing high-quality solutions to their customers.

{Company Name} takes pride in its ability to adapt to the changing needs of the industry and its customers. By incorporating Tungsten Carbide Bushing into their product line, the company is demonstrating their proactive approach to staying ahead of the competition and offering superior solutions that set the standard for quality and performance.

The use of Tungsten Carbide Bushing marks a significant milestone for {Company Name}, further solidifying their position as a leader in the industrial equipment manufacturing sector. With this latest enhancement, the company is poised to continue meeting and exceeding the expectations of their customers, while setting the bar for excellence in the industry.

About {Company Name}:

{Company Name} is a renowned manufacturer of industrial equipment, offering a comprehensive range of solutions for various industrial applications. With a focus on quality, innovation, and sustainability, the company has earned a strong reputation for delivering reliable and high-performance equipment to its customers. {Company Name} is committed to staying at the forefront of the industry by embracing the latest technologies and materials, ensuring that their products meet the evolving needs of the marketplace. For more information, visit www.companywebsite.com.

In conclusion, the implementation of Tungsten Carbide Bushing is a significant development for {Company Name}, underscoring their commitment to delivering high-quality, durable, and sustainable solutions to their customers. As the company continues to innovate and push the boundaries of what is possible in industrial equipment manufacturing, they are well-positioned to maintain their leadership in the industry and meet the demands of a rapidly evolving marketplace.

Company News & Blog

High-Quality Tungsten Carbide Bushing Dies: A Must-Have for Precision Machining

Tungsten Carbide Bushing Die, a critical component used in various industrial applications, is an essential part of the manufacturing process for a wide range of products. These bushing dies are known for their high strength, toughness, and resistance to wear, making them an ideal choice for demanding applications. One company that has been at the forefront of producing high-quality Tungsten Carbide Bushing Dies is {Company Name}. With years of experience and a strong commitment to innovation and quality, {Company Name} has established itself as a leader in the industry.{Company Name} was founded in {year} and has since grown to become a trusted name in the manufacturing of Tungsten Carbide Bushing Dies and other precision components. The company's state-of-the-art manufacturing facilities are equipped with the latest technologies and machinery, allowing them to produce high-precision components with tight tolerances and exceptional surface finishes.One of the key factors that set {Company Name} apart from its competitors is its focus on continuous research and development. The company invests heavily in R&D to explore new materials, manufacturing techniques, and designs that can further enhance the performance and durability of their products. This relentless pursuit of innovation has allowed {Company Name} to stay ahead of the curve and consistently deliver cutting-edge solutions to its customers.In addition to their commitment to innovation, {Company Name} also places a strong emphasis on quality control. Every Tungsten Carbide Bushing Die that rolls out of their production line undergoes rigorous testing to ensure that it meets the highest standards of quality and performance. This dedication to quality has earned {Company Name} a reputation for reliability and consistency, making them the go-to choice for many industrial manufacturers.Another key strength of {Company Name} is its team of highly skilled and experienced engineers and technicians. These professionals bring a wealth of knowledge and expertise to the table, allowing {Company Name} to tackle even the most complex engineering challenges with confidence. Whether it's customizing a bushing die to meet specific customer requirements or developing new solutions for emerging industry needs, the team at {Company Name} is always up to the task.Aside from their technical capabilities, {Company Name} is also known for its exceptional customer service. The company takes pride in building strong, long-lasting relationships with its clients, working closely with them to understand their needs and provide tailored solutions that address their unique requirements. This customer-centric approach has earned {Company Name} the trust and loyalty of many satisfied clients, cementing its position as a preferred partner in the industry.Looking ahead, {Company Name} remains committed to pushing the boundaries of what is possible in the field of Tungsten Carbide Bushing Dies and precision components. The company continues to explore new opportunities for growth and expansion, with a keen eye on emerging trends and technologies. Whether it's delving into new markets, expanding their product lineup, or further refining their manufacturing processes, {Company Name} is poised to lead the way forward.In conclusion, Tungsten Carbide Bushing Dies are a critical component in many industrial applications, and {Company Name} has emerged as a leading producer of these precision components. With a strong focus on innovation, quality, and customer satisfaction, {Company Name} has established itself as a trusted partner for many manufacturers. As the company continues to evolve and expand its capabilities, it is well-positioned to shape the future of the industry and meet the evolving needs of its clients.

Effective Guide for Tungsten Carbide Guide Rollers: A Comprehensive Overview

Title: Superior Tungsten Carbide Guide Roller Unveiled by Leading Manufacturing CompanyIntroduction:Innovative advancements in various industrial sectors continue to drive growth and enhance efficiency. In line with this spirit of progress, a renowned manufacturing company, recognized for its commitment to excellence, has recently unveiled an exceptional Tungsten Carbide Guide Roller. This cutting-edge product promises to revolutionize the manufacturing process by increasing precision, durability, and overall productivity. With its unparalleled features and exceptional performance, the new Tungsten Carbide Guide Roller is poised to become an indispensable tool in numerous industries.1. Unmatched Precision:The Tungsten Carbide Guide Roller sets a new standard in precision engineering. By utilizing state-of-the-art technology, this roller provides extreme accuracy during the manufacturing process. With its robust construction and perfectly balanced design, it adjusts effortlessly, ensuring precise guidance of materials, even in the most demanding production environments.2. Unrivaled Durability:Operating in high-stress conditions is a constant challenge in the manufacturing industry. To overcome this, the Tungsten Carbide Guide Roller possesses exceptional durability, allowing it to withstand extreme temperatures, wear, and corrosion. Its composition of tungsten carbide coated with a protective layer results in a roller that can withstand the harshest manufacturing conditions, significantly reducing maintenance costs and equipment downtime.3. Enhanced Productivity:Manufacturing companies are constantly seeking innovative tools that can optimize production and increase productivity. The Tungsten Carbide Guide Roller meets these demands by substantially reducing production time, thus significantly contributing to a streamlined workflow. Its impeccable surface finish minimizes friction and material buildup, resulting in improved production rates and reduced wastage. The enhanced productivity offered by this roller translates directly into increased profitability for industrial manufacturers.4. Versatility and Adaptability:To fulfill the diverse requirements of various industries, the Tungsten Carbide Guide Roller has been designed to adapt to a wide range of applications. Whether used in textile machinery, wire processing, or plastic films, this versatile roller provides consistently reliable performance across multiple sectors. The roller's adaptable nature contributes to its appeal, making it an indispensable component for numerous manufacturing processes.5. Commitment to Quality:Manufacturing companies can rest assured that by investing in the Tungsten Carbide Guide Roller, they are receiving a product of superior quality. The manufacturing company's commitment to excellence is evident throughout the production process, from raw material selection to stringent quality control measures. Stringent testing is conducted to ensure that every roller meets the highest quality standards before leaving the factory, instilling confidence in the end-users.Conclusion:The introduction of the Tungsten Carbide Guide Roller marks a significant advancement in the manufacturing industry. This pioneering product combines unmatched precision, unrivaled durability, enhanced productivity, versatility, and a commitment to quality. With its innovative design and exceptional performance, industrial manufacturers can expect seamless operations and increased profitability. As industries continue to evolve and demand the very best, the Tungsten Carbide Guide Roller stands as a testament to the tireless pursuit of excellence in engineering, providing a tangible solution to the challenges faced by manufacturers worldwide.

Durable Tungsten Carbide Wire Rolls for Industrial Applications

Tungsten Carbide Wire Rolls: The Ultimate Solution for Wire DrawingWire drawing is a manufacturing process used to reduce the cross-section of a wire by pulling the wire through a die or series of dies. This process is essential in the production of various wire products, including electrical wires, cables, and fencing. To ensure the efficiency and accuracy of the wire drawing process, manufacturers rely on high-quality tungsten carbide wire rolls.{Tungsten Carbide Wire Rolls} is a leading supplier of tungsten carbide wire rolls, known for their exceptional quality and performance. The company has been in the industry for over 20 years, providing innovative solutions for wire drawing applications across various industries. With a strong focus on research and development, {the company} has continually improved its products to meet the ever-evolving needs of the wire drawing industry.Tungsten carbide wire rolls are made from a combination of tungsten and carbon, resulting in a material that is extremely hard and wear-resistant. This makes them ideal for the demanding conditions of wire drawing, where the rolls are subjected to high pressures and abrasive forces. Compared to traditional steel rolls, tungsten carbide wire rolls offer superior durability and longevity, reducing the need for frequent replacement and maintenance.The unique properties of tungsten carbide also enable the production of wires with precise dimensions and surface finishes. This is crucial for industries that require high-quality wires, such as the electrical and automotive sectors. With {the company}'s tungsten carbide wire rolls, manufacturers can achieve greater consistency and accuracy in their wire drawing processes, leading to improved product quality and performance.In addition to their exceptional durability and precision, tungsten carbide wire rolls also offer improved productivity and cost savings. The extended lifespan of these rolls means reduced downtime for roll changes and maintenance, resulting in higher production efficiency. Furthermore, the superior wear resistance of tungsten carbide leads to reduced wear on the wire drawing equipment, minimizing the need for replacement parts and repairs.{The company} offers a wide range of tungsten carbide wire rolls to suit different wire drawing applications. Whether it's for fine wire drawing or heavy-duty cable production, {the company} provides customized solutions to meet specific customer requirements. With a strong emphasis on customer satisfaction, {the company} works closely with its clients to understand their needs and provide tailored solutions that optimize their wire drawing processes.As a trusted supplier in the wire drawing industry, {the company} maintains strict quality control measures to ensure the consistency and reliability of its products. All tungsten carbide wire rolls undergo rigorous testing and inspections to meet the highest industry standards. This commitment to quality has earned {the company} a reputation for excellence and reliability among its customers.In conclusion, tungsten carbide wire rolls from {the company} are the ultimate solution for wire drawing applications. With their unmatched durability, precision, and productivity benefits, these rolls have become indispensable tools for manufacturers across various industries. As the demand for high-quality wires continues to grow, {the company} remains at the forefront of innovation, continuously enhancing its products to meet the evolving needs of the wire drawing industry. For manufacturers looking to improve their wire drawing processes, {the company}'s tungsten carbide wire rolls offer a winning solution that delivers exceptional results.

The Advantages and Applications of Cemented Carbide YG15: A Comprehensive Guide

In recent news, a cemented carbide manufacturer has made significant progress in the development of their product - YG15 (brand name removed). The YG15 cemented carbide is a highly durable and wear-resistant material that is widely used in the manufacturing industry for various components.The YG15 cemented carbide is an alloy made from a combination of tungsten carbide and cobalt powder, which is blended together and then subjected to a sintering process to produce a solid, hard-wearing material. The YG15 cemented carbide has been tested against various types of wear and tear, including abrasion, corrosion, and impact, and has been found to be highly resistant against all forms of wear and tear.One of the unique features of YG15 cemented carbide is its excellent resistance to abrasion. Abrasion is a type of wear that is caused by the rubbing or scraping of two surfaces against each other, which can result in the surface becoming rough and dull. This type of wear can be particularly problematic in industrial applications, where components are subjected to constant abrasion, leading to high levels of wear and tear.YG15 cemented carbide is also highly resistant to corrosion, which is the process of materials gradually deteriorating due to exposure to environmental factors such as moisture, temperature, and chemicals. This makes YG15 cemented carbide an ideal material for use in harsh environments, such as those found in the oil and gas industry, where components are exposed to corrosive fluids.In addition to its excellent resistance to wear and tear, YG15 cemented carbide is also known for its high strength and durability. This makes it an ideal material for use in high-stress applications, such as those found in the aerospace and automotive industries.One of the key benefits of YG15 cemented carbide is its ability to be shaped and formed into various components. This makes it a versatile material that can be used to manufacture a wide range of products, including cutting tools, wear parts, and industrial machinery components.The manufacturer of YG15 cemented carbide prides itself on producing a high-quality product that is consistently reliable and meets the needs of its customers. The company has invested heavily in research and development to ensure that its products are at the forefront of technological advancements.In addition to providing high-quality products, the manufacturer of YG15 cemented carbide places a great deal of emphasis on customer service and support. This includes providing expert advice on product selection, as well as offering technical support and troubleshooting services to help customers get the most out of their products.Overall, YG15 cemented carbide is a highly durable and wear-resistant material that is widely used in the manufacturing industry for various components. Its excellent resistance to abrasion and corrosion, as well as its high strength and durability, make it an ideal material for use in high-stress applications. With its consistent reliability and commitment to customer service and support, the manufacturer of YG15 cemented carbide is a trusted and respected name in the industry.

The Versatility and Durability of High-Quality Tungsten Carbide Cutter Blades Revealed in Latest News

Tungsten Carbide Cutter Blade: The Heavy-Duty Precision Tool for Industry ApplicationsTungsten Carbide Cutter Blade, the precision tool that has been transforming the industry with its heavy-duty cutting capabilities, is a name that has become synonymous with excellent craftsmanship and reliability. Used in a wide range of industrial applications, Tungsten Carbide Cutter Blade has earned a reputation for being the go-to precision tool for the toughest jobs in construction, manufacturing, and even the metalworking industry.What Makes Tungsten Carbide Cutter Blade Unique?Tungsten Carbide Cutter Blade offers a unique combination of toughness, strength, and durability, which is why it is unmatched in the industry. It is specifically designed to outlast other blades and withstand heavy-duty cutting tasks that would otherwise require multiple blades, which saves time and improves productivity.One of the unique features of the Tungsten Carbide Cutter Blade is its use of tungsten carbide, one of the toughest and densest materials on the planet. When combined with other metals such as cobalt, tungsten carbide forms a compound known as cemenite, which is a very hard and durable material that can withstand high levels of stress. The result is a blade that can cut through almost any material with ease, including wood, metal, and even concrete.Another key feature that sets Tungsten Carbide Cutter Blade apart from other blades on the market is its exceptional edge retention. The blade can maintain a sharp edge for longer periods, which reduces the need for frequent sharpening and replacement, making it more cost-effective in the long run.Applications of Tungsten Carbide Cutter BladeTungsten Carbide Cutter Blade can be used in a wide range of applications, including:1. Construction – Tungsten Carbide Cutter Blade can cut through almost any material used in construction, such as asphalt, concrete, bricks, and stones, making it an essential tool for builders, contractors, and masons.2. Metalworking – Cutting metals such as steel and aluminum requires a blade that can withstand high temperatures and stress. Tungsten Carbide Cutter Blade can handle these conditions, making it a top choice for this industry.3. Manufacturing – Tungsten Carbide Cutter Blade is also used in manufacturing, as it can easily cut through materials like plastics, composites, and fibers, while maintaining its sharp edge for longer periods.Company Introduction and InnovationInnovation is at the heart of Tungsten Carbide Cutter Blade's success. The company has been a leader in the industry for over two decades, producing high-quality precision tools that are designed to make cutting tasks easier and more efficient.Tungsten Carbide Cutter Blade's dedication to innovation is evident in the numerous patents it holds for its cutting-edge products, such as its effective design, advanced manufacturing techniques, and rigorous quality control measures.In addition to cutting-edge research and development, Tungsten Carbide Cutter Blade also invests heavily in its manufacturing processes. The company employs state-of-the-art equipment and processes to ensure the highest quality and precision for each blade. From the initial design stage to the final product, Tungsten Carbide Cutter Blade leaves no stone unturned in its drive for perfection.ConclusionTungsten Carbide Cutter Blade is a precision tool that is unmatched in its toughness, strength, and durability. It is the go-to tool for heavy-duty cutting tasks in a wide range of industrial applications, including construction, metalworking, and manufacturing. Its exceptional edge retention and cutting capabilities make it a cost-effective investment that saves time and improves overall productivity. With Tungsten Carbide Cutter Blade, you can be sure of getting the best in heavy-duty cutting tools, made with an unwavering commitment to quality.

Durable Tungsten Carbide: A Strong and Long-Lasting Material Option

{Company name}, a leading manufacturer and supplier of tungsten carbide products, is proud to announce the development of a new line of products that offer unparalleled hardness and durability. With a focus on innovation and quality, {Company name} is dedicated to providing customers with cutting-edge solutions for their toughest challenges.Tungsten carbide is a versatile material known for its exceptional hardness and wear resistance. It is commonly used in a variety of industrial applications, including cutting tools, mining equipment, and wear parts. {Company name} has been at the forefront of tungsten carbide technology, pushing the boundaries of what is possible with this remarkable material.The new line of products from {Company name} features a unique blend of tungsten carbide that has been specially formulated to maximize hardness and toughness. This advanced material, known as XXC, delivers superior performance in the most demanding environments, standing up to the rigors of heavy-duty use."We are excited to introduce our latest innovation in tungsten carbide technology," said John Smith, CEO of {Company name}. "Our team of engineers and material scientists have worked tirelessly to develop a product that sets a new standard for hardness and durability. We believe that our new XXC line will revolutionize the industry and provide our customers with a distinct competitive advantage."The key to the exceptional hardness of XXC lies in its microstructure, which is finely tuned to maximize strength and wear resistance. This allows the material to maintain its sharpness and integrity even under extreme conditions, ensuring long-lasting performance and reliability.In addition to its exceptional hardness, XXC also offers superior toughness, making it ideal for applications where impact and shock resistance are crucial. This combination of hardness and toughness makes XXC the perfect choice for a wide range of high-performance tools and components.{Company name} is committed to delivering the highest quality products to its customers, and the introduction of the XXC line is a testament to this dedication. By continually pushing the boundaries of material science and engineering, {Company name} is able to provide its customers with the most advanced solutions for their specific needs."We are proud to be at the forefront of tungsten carbide technology," said Smith. "With our new XXC line, we are raising the bar for hardness and durability, setting a new standard for the industry. We are confident that our customers will see the immediate benefits of this remarkable material."As {Company name} continues to expand its product offerings and push the limits of what is possible with tungsten carbide, the company remains focused on providing innovative solutions that help its customers succeed. With the introduction of the XXC line, {Company name} is once again demonstrating its commitment to excellence and its position as a leader in the industry.For more information about {Company name} and its new line of XXC products, visit {company website} or contact the company directly to speak with a representative. With a reputation for quality and innovation, {Company name} is the preferred choice for customers who demand the best in tungsten carbide technology.

Discover the Efficiency and Durability of Cutting Tooth for Carbide Materials

Title: Innovative Carbide Cutting Tooth Revolutionizes Cutting Efficiency in Various IndustriesIntroduction:In today's rapidly evolving industries, the demand for efficient cutting tools that can withstand heavy workloads and offer superior performance has never been higher. Recognizing this pressing need, {Company Name}, a leading manufacturer of industrial tools, has introduced a groundbreaking Carbide Cutting Tooth. With its exceptional cutting prowess and durability, this advanced tool is set to transform the cutting processes across several sectors, including construction, mining, and forestry.Section 1: Evolution of Cutting ToolsThe field of cutting tools has experienced several evolutionary milestones, driven by the constant pursuit of improved performance and efficiency. Traditional cutting tools made of high-speed steel (HSS) have gradually been replaced by carbide-tipped alternatives due to their enhanced durability and wear resistance. Carbide, being a composite material of tungsten carbide particles embedded within a metallic binder, offers remarkable hardness and toughness necessary for heavy-duty operations.Section 2: Introducing the Innovative Carbide Cutting Tooth{Company Name} has utilized advanced research and development techniques to create a highly efficient Carbide Cutting Tooth that exceeds expectations. This innovative tool boasts a unique design, combining a trapezoidal shape with deep gullets, allowing for efficient chip evacuation during cutting operations, thus minimizing downtime and maximizing productivity.Section 3: Unparalleled Durability and LongevityOne of the key advantages of the Carbide Cutting Tooth is its unparalleled durability. The cutting edges incorporate high-quality carbide inserts, ensuring exceptional wear resistance even when subjected to extreme cutting conditions. This durability translates into reduced tool replacement and maintenance costs, ultimately boosting overall operational efficiency.Section 4: Enhanced Cutting PerformanceThe Carbide Cutting Tooth is engineered to deliver enhanced cutting performance across various materials. Whether cutting through concrete, wood, or metal, the advanced tooth design ensures precise cuts with reduced vibrations and increased stability. This cutting-edge technology facilitates smoother operations, resulting in superior finishing and reduced material wastage.Section 5: Application across IndustriesThe versatile Carbide Cutting Tooth finds applications in numerous industries. In construction, it offers significant advantages in road milling, trenching, and concrete demolition. In the mining sector, the tool exhibits exceptional performance in rock cutting and tunneling operations. Moreover, it proves valuable in the forestry industry for various applications, such as land clearing, tree felling, and branch trimming. Its widespread usage across these sectors demonstrates its adaptability and effectiveness.Section 6: Environmental Impact and Safety FeaturesIn line with the company's commitment to sustainability, the Carbide Cutting Tooth incorporates various safety features to minimize its environmental impact. High-efficiency chip evacuation mechanisms prevent dust and debris accumulation, reducing the release of harmful particles into the environment. Additionally, the cutting tooth design promotes operator safety by minimizing kickback and vibration, ensuring a secure working environment.Section 7: Market Outlook and ConclusionThe introduction of the innovative Carbide Cutting Tooth by {Company Name} is set to revolutionize the cutting tool market. Its superior cutting performance, exceptional durability, and versatility across industries make it the go-to choice for professionals seeking efficiency and reliability in their operations. With its potential to boost productivity, reduce costs, and improve overall cutting efficiency, this advanced tool is destined to be a game-changer for the global industry.In conclusion, the remarkable Carbide Cutting Tooth developed by {Company Name} signifies a significant leap in cutting tool technology. Its intelligent design, durability, and enhanced cutting performance are poised to transform cutting processes in construction, mining, and forestry sectors. As the demand for efficient cutting tools continues to soar, the industry is set to embrace this innovative solution that promises unparalleled efficiency, reduced costs, and improved overall outcomes.

Customized Carbide: The Ultimate Solution for Your Carbide Needs

Carbide Customized, a leading manufacturer of customized carbide tools for various industries, is making headlines with their latest innovation. The company has recently introduced a revolutionary new product that is set to change the game for manufacturers and engineers across the globe.Carbide Customized has been in the business of producing high-quality carbide tools for over two decades. With a strong focus on precision, quality, and innovation, the company has established itself as a trusted name in the industry. Their products are used in a wide range of applications, including aerospace, automotive, medical, and general machining.The latest product from Carbide Customized is a result of years of research and development. The company's team of skilled engineers and designers have worked tirelessly to create a tool that offers unprecedented levels of performance and durability. The new product is designed to meet the ever-increasing demands of modern manufacturing processes, where precision and efficiency are paramount."We are extremely proud to introduce our latest innovation to the market," says John Smith, CEO of Carbide Customized. "We believe that this new product will revolutionize the way manufacturers and engineers approach their work. It offers unparalleled performance and versatility, making it a game-changer for our customers."One of the key features of the new product is its customizable nature. Customers can work closely with Carbide Customized's team to create tools that are tailored to their specific needs and requirements. This level of customization ensures that the tools are perfectly suited to the unique challenges and demands of each individual application.In addition to its customizable nature, the new product also boasts exceptional durability and wear resistance. This means that the tools can withstand the rigors of heavy-duty machining and cutting, resulting in longer tool life and reduced downtime for maintenance and replacement.Furthermore, the new product is designed to deliver superior performance in terms of cutting speed and precision. This means that manufacturers and engineers can achieve higher levels of productivity and efficiency, ultimately leading to cost savings and improved profitability.The introduction of this groundbreaking product has been met with great enthusiasm from Carbide Customized's customers. Many have already expressed their interest in exploring the possibilities that the new tool has to offer, and the company is gearing up for a surge in demand in the coming months."We have been receiving overwhelming feedback from our customers, and we are excited to see the impact that this new product will have on the industry," says Smith. "We are confident that it will set a new standard for performance and reliability, and we are committed to ensuring that our customers have access to the very best tools available."Looking ahead, Carbide Customized is planning to continue its investment in research and development to further push the boundaries of innovation in the carbide tool industry. The company is dedicated to staying at the forefront of technological advancements and delivering cutting-edge solutions that empower their customers to thrive in a rapidly evolving market.As the industry continues to evolve, Carbide Customized remains steadfast in its commitment to providing top-quality tools that meet the evolving needs of manufacturers and engineers. With its latest innovation, the company is poised to solidify its position as a leader in the carbide tool industry and make a lasting impact on the way manufacturing processes are approached worldwide.

High-Quality Cold Punching Dies for Precision Metal Fabrication

Cold Punching Dies are essential tools used in the manufacturing industry, particularly in the production of metal, plastic, and other materials. They are crucial for shaping, cutting, and forming products with precision and accuracy. These dies are used in various industries such as automotive, aerospace, electronics, and construction, among others. {} is a reputable company that specializes in the production of high-quality cold punching dies. With a strong focus on innovation and precision engineering, the company has established itself as a leader in the industry. Their dedication to quality and customer satisfaction has earned them a loyal customer base and a strong reputation for excellence.The cold punching dies produced by {} are known for their durability, precision, and superior performance. The company utilizes advanced manufacturing techniques and cutting-edge technology to ensure that their products meet the highest standards of quality. Their team of skilled engineers and technicians work tirelessly to develop innovative solutions that meet the evolving needs of their customers.In addition to their commitment to quality, {} is also dedicated to sustainability and environmental responsibility. The company is constantly exploring new ways to reduce waste, minimize energy consumption, and mitigate their environmental impact. By prioritizing sustainability, they are not only contributing to a greener planet but also setting an example for the industry as a whole.One of the key strengths of {} is their ability to customize cold punching dies according to the specific requirements of their customers. They understand that every manufacturing process is unique, and they work closely with their clients to develop tailored solutions that meet their exact needs. This personalized approach has earned {} a strong reputation for flexibility and customer service.Furthermore, {} places a strong emphasis on research and development. They are continually investing in new technologies and processes to improve their products and stay ahead of the competition. This commitment to innovation has allowed them to develop cutting-edge solutions that have helped their customers enhance their manufacturing processes and achieve greater efficiency.{}'s commitment to excellence extends beyond their products to their customer service. They understand the importance of building strong relationships with their clients and providing ongoing support and assistance. Whether it's technical advice, troubleshooting, or training, {} is there to support their customers every step of the way.As a result of their dedication to quality, innovation, sustainability, and customer service, {} has earned the trust of a wide range of customers across various industries. Their cold punching dies have become synonymous with precision, reliability, and performance, making them the go-to choice for many manufacturing companies around the world.In conclusion, {} has established itself as a leading manufacturer of cold punching dies, thanks to their unwavering commitment to quality, innovation, sustainability, and customer service. With a focus on precision engineering and personalized solutions, they have set themselves apart in the industry and earned the trust and loyalty of their customers. As they continue to innovate and push the boundaries of what is possible, {} is poised to remain a key player in the manufacturing industry for years to come.

Discover the Latest Advances in Ground Tungsten Carbide Bushing Technology

article:Ground Tungsten Carbide Bushing: The Revolutionary Innovation in the Manufacturing IndustryTechnology plays an essential role in shaping the manufacturing industry around the globe. It has been observed that the companies' adept at embracing the latest technology and innovation lead the market. The introduction of Ground Tungsten Carbide Bushing is one of those revolutionary innovations that have transformed the manufacturing industry. It is an innovative product that has made the manufacturing process more efficient and cost-effective.Ground Tungsten Carbide Bushing, also known as Tungsten Carbide Sleeve, is a robust and versatile material used in numerous applications. It is a composite of Tungsten and Carbide that is fused together through the process of sintering. It is also used in various industrial sectors, such as automotive, aerospace, chemical, and mining industries.Ground Tungsten Carbide Bushing is an ideal solution in applications requiring resistance to abrasion, wear, corrosion, and impact, as it offers excellent hardness and strength. It also has an outstanding thermal and electrical conductivity that makes it a suitable option for electrical contacts and heating applications.The product is created by mining tungsten and carbon elements, which are then ground separately to the desired particle size. The finished product of Tungsten Carbide Sleeve is created through pressure and heat, where the tungsten and carbon powders are molded and sintered into a homogeneous mass. This unique combination of tungsten and carbon offers excellent wear resistance and toughness.The Ground Tungsten Carbide Bushing is a reliable solution that has proven its merit in the manufacturing industry. The use of this high-quality material offers numerous benefits to the companies that adopt it. The ground tungsten carbide bushing offers a long-lasting and durable solution resulting in reducing maintenance costs. It also enhances the service life of the equipment and machinery that utilizes this innovative product.Moreover, the use of tungsten carbide bushing reduces the frequency of equipment maintenance and repairs, thereby enhancing its efficiency, which leads to increased productivity and profitability. The ground tungsten carbide bushing has become a viable option for manufacturing companies that are looking for cost-effective solutions by providing positive impacts on their bottom line.The use of this innovation has positively impacted the environment, as it reduces the need for manufacturing replacement parts that require considerable resources. Instead, tungsten carbide sleeves can be installed in machinery, reducing the need for frequent replacements, ultimately resulting in reducing carbon footprints.As mentioned earlier, the Ground Tungsten Carbide Bushing has various industrial applications. For example, in the automotive industry, it is used in different parts of engine components, like oil pumps and camshafts, because of its superior strength and hardness. In the Aerospace industry, it is used in different parts of Airplanes, such as landing gears, and nose wheels, because of its wear and corrosion resistance capabilities. In the chemical industry, it is used in various rotating equipment, such as centrifugal pumps, as it can withstand corrosion and high temperatures.Talk about the company and what sets it apart in the marketThe company was established in (enter year) and has been at the forefront of technological innovation ever since. The company prides itself on providing innovative solutions by leveraging technological advancements for its manufacturing processes. The company aims to promote the use of sustainable alternatives in manufacturing, and the introduction of Ground Tungsten Carbide Bushing is a perfect example of that.The company’s commitment to providing innovative solutions has set it apart in the market. Its state-of-the-art production processes ensure that the quality of the Ground Tungsten Carbide Bushing is second to none. The company’s success is also credited to its relentless pursuit of excellence and ability to cater to its customers’ unique requirements.ConclusionGround Tungsten Carbide Bushing is a revolutionary innovation in the manufacturing industry. The use of this innovative material offers a cost-effective solution that enhances equipment efficiency and reduces maintenance costs. Its wear and corrosion resistance capabilities make it an ideal choice for various industrial applications, including the automotive, aerospace, chemical, and mining industries. The company’s commitment to technological innovation and sustainability makes it a frontrunner in the manufacturing industry. The use of Ground Tungsten Carbide Bushing has improved the manufacturing industry's efficiency and service life of the machinery, which has resulted in increased profitability.