Discover the Superiority of Tungsten Carbide Wire Drawing Dies in the News

By:Admin

Tungsten carbide wire drawing dies are crucial components used in the manufacturing process of various wires. These dies are known for their exceptional hardness, wear resistance, and durability, making them ideal for drawing high-quality wires of different diameters. [Company name]'s extensive lineup of tungsten carbide wire drawing dies caters to the diverse needs of various industries, including automotive, electronics, telecommunications, and construction.

The company's extensive experience and expertise in the field of manufacturing wire drawing dies have enabled them to develop cutting-edge solutions that meet the rigorous demands of the industry. Their team of engineers and technicians is dedicated to continuous research and development, ensuring that their products are at the forefront of technological advancements.

One of the key features of [Company name]'s tungsten carbide wire drawing dies is their superior surface finish, which ensures smooth wire drawing operations. The dies are meticulously engineered to minimize surface defects and reduce wire breakage, resulting in improved production efficiency and cost-effectiveness.

Moreover, [Company name] understands that every customer has unique requirements and specifications. Therefore, they offer customized solutions tailored to the specific needs of each client. Whether it is a specific wire shape, size, or coating requirement, the company's experts work closely with the clients to design and manufacture dies that meet their exact specifications.

In addition to their commitment to quality, [Company name]'s commitment to environmental sustainability is commendable. They adhere to strict environmental standards throughout their manufacturing processes, ensuring minimal impact on the environment. Their sustainable practices and responsible approach have earned them certifications and recognition from various regulatory bodies.

Furthermore, customer satisfaction is at the core of [Company name]'s business ethos. The company strives to provide exceptional service and support to its customers, ensuring that their needs are met promptly and efficiently. Their dedicated customer service team is readily available to address any queries or concerns, ensuring a seamless experience for their clients.

To stay ahead in a highly competitive market, [Company name] also invests in cutting-edge technology and machinery. Their state-of-the-art manufacturing facilities are equipped with the latest equipment, enabling them to produce wire drawing dies with unmatched precision and quality.

As a testament to their commitment to excellence, [Company name] has earned a stellar reputation in the industry. Their products are known for their outstanding performance, durability, and long service life. Countless satisfied customers testify to the superior quality and reliability of [Company name]'s tungsten carbide wire drawing dies.

With their unwavering dedication to innovation, quality, and customer satisfaction, [Company name] continues to be a leader in the tungsten carbide wire drawing dies industry. The company's relentless pursuit of excellence and commitment to meeting the evolving needs of its customers ensure that it will remain at the forefront of the industry for years to come.

As demand for high-quality wires continues to grow across various industries, [Company name]'s tungsten carbide wire drawing dies are set to play a crucial role in meeting this demand. With their superior performance, unmatched quality, and exceptional customer support, [Company name] is poised to shape the future of the wire drawing industry.

Company News & Blog

The Latest News About High-Quality Tungsten Carbide Rings

Tungsten Carbide Rings: The Ultimate Symbol of Love and StrengthWedding rings are one of the most essential part of a wedding ceremony that symbolizes love, commitment and loyalty towards each other. It is not only a piece of jewelry, rather a sentiment that you wear around your finger and cherish for the rest of your life. With various alternatives available, couples are now opting for tungsten carbide rings instead of traditional gold or platinum bands. Its unique nature, unparalleled durability and its lower price point are some of the reasons why it has become the preferred choice for couples around the world.Tungsten carbide rings are made by combining tungsten with carbon atoms, which creates a tough and durable material, resistant to wear and tear. Due to its resistance to scratching, fading, and damage, it is the perfect choice for a wedding band. These rings are made using advanced technology, which allows for intricate designs and engravings, which makes each ring unique. Tungsten carbide rings have a masculine and classic look, perfect for both men and women.There are many advantages of choosing tungsten carbide rings over traditional metals like gold or platinum. Firstly, it is much more durable. It can withstand day-to-day wear and tear, and is resistant to scratches and damage. Which means, the ring will look just as good years after your wedding day. Secondly, tungsten carbide rings are hypoallergenic which means they are ideal for those who have sensitive skin allergies. Thirdly, it is available at a lower price point when compared to gold or platinum, without compromising on its unique look and strength. Additionally, tungsten carbide rings can be customized to any pattern, finish or color which provides the perfect opportunity to add a personal touch to your wedding ring.For couples looking to purchase tungsten carbide rings, one brand that stands out is {}. The company has been in existence for over 16 years and has perfected the art of designing and manufacturing tungsten carbide rings. Their focus on quality and precision has made them one of the leading providers of tungsten carbide rings. In addition to traditional wedding bands, the brand offers a range of tungsten carbide engagement rings that come in a variety of styles, finishes and colors, the perfect choice to express your love and commitment to your partner.In addition to its traditional designs, {} takes it up a notch with its specially curated collections designed for couples who want their rings to stand out. The Black Collection, a favorite among couples who are looking for a more contemporary design, features a black tungsten carbide finish with rose gold or silver accents. The Carbon Collection, on the other hand, features a combination of black and silver tungsten carbide with carbon fiber inlays, providing a sleek and modern edge. The Infinity Collection, with its signature infinity symbol, is a reminder of the eternal love and commitment between two individuals.At {}, the mission is to provide couples with a symbol of love and strength that lasts a lifetime. In addition to providing the perfect wedding band, the brand also offers engraving services that add a personalized touch to the ring. {} strives to exceed expectations by providing exceptional customer service, making the journey of selecting a wedding band a memorable one.Tungsten carbide rings are the perfect choice for couples looking for a wedding band that is unique, durable and affordable. {} provides a range of options that is sure to surpass all expectations. The collection of tungsten carbide rings offered by the brand is designed to cater to different personalities and styles, ensuring that each couple finds the perfect match. With a focus on quality, precision and customer service, {} has become the go-to destination for couples looking for the ultimate symbol of love and strength.

Enhance Your Turning Applications with High-Performance Carbide Inserts

Carbide Inserts for Turning Applications Offer Enhanced Durability and PrecisionCarbide inserts for turning applications have emerged as one of the popular cutting tools in the manufacturing industry. These inserts are designed with high-performance materials, which enhance their durability and precision capabilities. Carbide inserts are cutting-edge technology tools that can be used for turning, milling, drilling, and other cutting applications.A leading manufacturer and supplier of carbide inserts has recently introduced a range of carbide inserts for turning applications. The company's new products are designed to cater to the needs of all manufacturing industries, ensuring that clients receive superior quality and precision tools.The company has been providing the manufacturing industry with premium quality carbide inserts for more than a decade. Their team of experts has vast experience in the field of machining technology, and they employ innovative techniques to produce cutting-edge products that cater to the needs of the clients.Carbide inserts are widely used in turning applications because of their superior quality and precision capabilities. They are made from a combination of tungsten carbide and cobalt, which makes them harder than high-speed steel. Carbide inserts are also resistant to high temperatures, ensuring that they can withstand the heat generated during the cutting process.The company's new line of carbide inserts for turning applications is designed to offer improved performance, higher durability, and precision. The new range is available in different grades and designs, making it suitable for multiple turning applications, from roughing to finishing. The range includes inserts, inserts with chipbreakers, and inserts for heavy-duty roughing, among others.The company's carbide inserts for turning applications are highly versatile and can be used for a wide range of materials. They are ideal for cutting hard materials like steel, stainless steel, cast iron, and exotic alloys. The inserts' smooth finish and stable performance ensure that there is no chipping or breakage during the cutting process, which makes them ideal for industrial applications.Carbide inserts are designed to provide high accuracy and precision. The inserts' cutting edge produces a smooth finish, making it ideal for applications that require a high degree of precision. Additionally, carbide inserts are designed to produce chips that are easy to manage and dispose of, thus reducing the machine's downtime.The new range of carbide inserts for turning applications from the company is also cost-effective. Carbide inserts are designed to last longer than high-speed steel, which reduces the need for frequent changes and replacement. Additionally, the company's cost-effective pricing policy ensures that clients can obtain high-quality, reliable carbide inserts at an affordable price.The company's carbide inserts for turning applications are also environmentally friendly. Carbide inserts produce chips that can be recycled, which reduces manufacturing waste and environmental pollution. The company's products are designed with environmental responsibility in mind, and they are committed to reducing the carbon footprint associated with manufacturing.The company's carbide inserts for turning applications are easy to use and maintain. The inserts' high-performance materials make them resistant to wear and tear, which means less maintenance is required. Additionally, the company provides extensive technical support to ensure that clients can achieve the best results from their products.The company's commitment to client satisfaction is evident in the quality of their products and services. They have a team of experts who are always available to provide technical support and advice on the best carbide inserts for specific applications. The company also offers customized carbide inserts, ensuring that clients can obtain products that cater to their specific needs.In conclusion, carbide inserts for turning applications from the company are a game-changer in the manufacturing industry. They offer enhanced durability, precision, and versatility, making them ideal for a wide range of turning applications. The company's commitment to quality and affordability ensures that clients can obtain high-quality products at an affordable price, while their eco-friendly approach reduces manufacturing waste and environmental pollution.

Cemented Carbide Rods: A Comprehensive Guide to Enhance Your Industrial Applications

Cemented Carbide Rods: Revolutionizing the Manufacturing IndustryIn today's competitive manufacturing industry, companies are constantly seeking innovative solutions to enhance their production processes and increase overall efficiency. One such groundbreaking innovation is the development and application of cemented carbide rods. These remarkable tools have revolutionized various sectors, providing incredible strength and durability while minimizing wear and tear, ultimately reducing a company's maintenance costs.Cemented carbide rods, often referred to as tungsten carbide rods, are widely used in metalworking, woodworking, and other industries that rely on precision cutting and shaping. This innovative material is the result of combining tungsten carbide, a ceramic compound, with a binding metallic cobalt or nickel. The combination offers exceptional hardness and resistance to heat, providing an ideal material for manufacturing tools that can withstand extreme conditions.One company at the forefront of cemented carbide rod production is (company name), a renowned leader in the manufacturing and distribution of industrial cutting tools and equipment. With years of experience and a commitment to quality, (company name) has become a trusted partner for businesses seeking reliable and long-lasting cemented carbide rods.Initially founded in (year), (company name) has evolved into a global player, catering to a wide range of industries including automotive, aerospace, and construction. The company's cemented carbide rods have gained significant popularity due to their exceptional performance and reliability, enabling businesses to improve their productivity and stay ahead in today's competitive market.One of the key advantages of cemented carbide rods is their impressive hardness. With a hardness rating of up to 90 HRA (Rockwell Hardness A), these rods outperform traditional steel and high-speed steel tools, ensuring efficient cutting and shaping processes even under the most demanding circumstances. This tremendous durability translates into longer tool life, reducing the frequency of tool replacement and ultimately saving manufacturing companies significant costs.Moreover, cemented carbide rods exhibit remarkable resistance to wear and tear. The binding metallic cobalt or nickel acts as a protective layer, preventing the rods from deteriorating or losing their sharpness over time. This characteristic allows (company name)'s cemented carbide rods to maintain their cutting edge, reducing the need for frequent re-sharpening or replacement. As a result, businesses using these rods experience enhanced and uninterrupted production cycles, increasing their overall efficiency.Another critical feature of cemented carbide rods is their exceptional resistance to heat. The combination of tungsten carbide and metallic binders results in a material capable of withstanding high temperatures, making it suitable for operations involving intense heat generation. Traditional tools often degrade under such conditions, leading to productivity slowdowns and potential damage to the workpiece. In contrast, cemented carbide rods offer superior heat resistance, ensuring uninterrupted workflow and consistent precision even in the most challenging environments.In addition to the superior physical properties of cemented carbide rods, (company name) constantly focuses on research and development to optimize their performance. By utilizing cutting-edge technology and collaborating with experts in the field, the company consistently introduces innovative designs and improvements to its product lineup. This commitment to innovation allows (company name) to stay ahead of the competition and provide its customers with state-of-the-art cemented carbide rods that meet the evolving needs of the manufacturing industry.Furthermore, (company name) recognizes the importance of providing comprehensive technical support and guidance to its customers. The company's team of experts ensures that clients understand the correct usage and maintenance procedures associated with cemented carbide rods, thus maximizing their longevity and effectiveness. This dedication to excellent customer service has established (company name) as a trusted and reliable partner in the manufacturing sector.In conclusion, cemented carbide rods have transformed the manufacturing industry, empowering businesses to achieve higher levels of productivity and efficiency. With exceptional hardness, resistance to wear and tear, and heat resistance, these robust tools offer unmatched durability and reliability. As a leading provider of cemented carbide rods, (company name) continues to shape the industry by delivering cutting-edge solutions and unwavering customer support. As manufacturing continuously evolves, these tools will undoubtedly play a central role in driving innovation and progress.

High-Quality Cold Forging Die Made of Tungsten Carbide

As one of the most versatile and valuable metals, tungsten has long been a favored material in the manufacturing industry. And when it's combined with carbon, it forms a substance called tungsten carbide. This material is widely used in various applications, including mining, automotive, construction, and aerospace. One of the most significant uses of tungsten carbide is in the manufacturing of forging dies. And a leading company with vast experience in this field is making strides in this industry with their innovative Tungsten Carbide Cold Forging Die technology.Headquartered in the heart of Japan, this company has built a reputation for excellence in the manufacturing of tungsten carbide tools and dies. They offer a wide range of products to meet the needs of various industries, including stamping dies, drawing dies, and cold forging dies.The company's Cold Forging Dies are specially designed to provide high-quality finished products while minimizing manufacturing costs. Cold forging is a process that involves shaping a metal part at room temperature using a die punch and a blank. This process comes with numerous benefits, such as increased strength, improved dimensional accuracy, and reduced material waste. Cold Forging Dies play a crucial role in ensuring the quality and efficiency of the cold forging process.With their extensive knowledge and experience, the company has developed a process for manufacturing Tungsten Carbide Cold Forging Dies that outperforms traditional dies on every level. The Tungsten Carbide material provides exceptional durability and wear resistance, making it ideal for high-volume manufacturing processes. In addition, this technology reduces tooling costs significantly, as it boasts a longer lifespan than traditional die materials.This cutting-edge technology also offers versatility in the manufacturing process. The company's Tungsten Carbide Cold Forging Dies are adaptable to many cold forging processes, including thread forming, swaging, extruding, and bending. The versatility of the dies ensures that manufacturers can produce reliable products with superior finish and accuracy within a shorter time span.Moreover, the company's Tungsten Carbide Cold Forging Dies are highly customizable, so they can be designed to fit perfectly into any particular manufacturing process. With the help of advanced software and equipment, the company can deliver tailor-made solutions that meet the specific requirements of their clients.The company's commitment to innovation and excellence has propelled them to the forefront of the manufacturing industry. They attribute their success to their astute attention to detail, strict quality control measures, and a motivated workforce. They take pride in delivering superior quality products that exceed their client's expectations and meet the needs of various manufacturing sectors.In conclusion, the company's Tungsten Carbide Cold Forging Dies technology is a game-changer in the manufacturing industry. It lowers production costs, reduces material waste, and improves overall manufacturing efficiency. It also offers versatility and customizability, making it ideal for various manufacturing processes. With this innovative technology, the company has set the standard for excellence in tungsten carbide die manufacturing and is poised to continue its remarkable growth into the future.

Premium Tungsten Carbide Roller: Bringing Unparalleled Polished Finishing

Title: Cutting-Edge Tungsten Carbide Roller Revolutionizes Manufacturing IndustryIntroduction:In our rapidly evolving manufacturing industry, innovation and cutting-edge technology continue to enhance production processes and improve product quality. One such revolutionizing development comes in the form of the Polished Tungsten Carbide Roller, developed by a renowned industry leader (company name).Groundbreaking Technology Enhancing Manufacturing Processes:Tungsten carbide possesses exceptional hardness and resistance to wear, making it an ideal material for manufacturing rollers used in various industries. By incorporating state-of-the-art polishing techniques, the (company name) Polished Tungsten Carbide Roller has taken the performance and efficiency of manufacturing processes to unprecedented heights.Precision and Enhanced Durability:The innovative design of the Polished Tungsten Carbide Roller ensures unparalleled precision, enabling manufacturers to achieve superior results in their production lines. The roller's polished surface significantly reduces friction, resulting in reduced wear and tear. This not only leads to enhanced durability but also extends the product's lifespan, reducing maintenance costs for manufacturers.Versatility Across Industries:The Polished Tungsten Carbide Roller caters to a diverse range of industries, including steel, aluminum, plastic, textile, and paper. Its versatility lies in the roller's ability to withstand extreme environments, high temperatures, corrosive chemicals, and heavy loads. This adaptability ensures that manufacturers can benefit from this groundbreaking technology across various applications.Smoother Operations and Improved Product Quality:With its reduced friction and enhanced durability, the Polished Tungsten Carbide Roller contributes to smoother operations, minimizing downtime and maximizing production efficiency. Its high precision and surface finish guarantee consistent and accurate results, thereby improving product quality and reducing the margin of error.Cost and Energy Efficiency:In addition to its exceptional performance, the Polished Tungsten Carbide Roller also promotes cost and energy efficiency. Its high wear resistance ensures less frequent replacements and maintenance, resulting in reduced operational costs for manufacturers. Additionally, the roller's improved efficiency minimizes energy consumption, making it an environmentally friendly choice.Commitment to Quality Assurance and Safety:As a leader in the manufacturing industry, (company name) prioritizes quality assurance and safety standards. The Polished Tungsten Carbide Roller undergoes rigorous testing and adheres to stringent quality control measures, ensuring that each roller meets or exceeds industry specifications. This commitment to excellence guarantees customer satisfaction and reliable performance for manufacturers in various fields.Global Reach and Customer Satisfaction:Backed by years of research and development, (company name) has built a strong reputation for delivering superior products worldwide. The Polished Tungsten Carbide Roller has garnered positive feedback from clients across the globe, who appreciate the roller's remarkable performance, increased efficiency, and unmatched durability. Customer satisfaction remains at the core of (company name)'s mission, driving them to continually innovate and meet the evolving needs of the industry.Conclusion:The Polished Tungsten Carbide Roller developed by (company name) has emerged as a game-changer in the manufacturing industry, enabling manufacturers to achieve unparalleled precision, efficiency, and durability. Through its innovative design and incorporation of cutting-edge polishing techniques, this revolutionary roller has set new standards for manufacturing processes across a wide range of industries. With its global success and commitment to customer satisfaction, (company name) continues to pave the way for future advancements in the manufacturing industry.

Top 5 Durable and Efficient Tools for Your Workshop

[Company Name] Introduces Superior Tungsten Carbide Tools for Enhanced Efficiency and Productivity[City name, Date] - [Company Name], a leading manufacturer of cutting-edge industrial tools, has unveiled its latest line of premium-quality tungsten carbide tools. Leveraging its extensive expertise in tool manufacturing, the company aims to cater to the increasing demand for high-performance tools in diverse industries.With a strong commitment to delivering innovative solutions, [Company Name] has invested significant resources into research and development, resulting in the creation of state-of-the-art tungsten carbide tools. These tools are designed to not only enhance efficiency and productivity but also deliver unparalleled precision and durability.Tungsten carbide is a compound known for its exceptional hardness and resistance to wear and tear, making it an ideal material for tool manufacturing. By combining tungsten carbide with other sophisticated alloys, [Company Name] has created a wide range of tools suitable for various applications, including cutting, drilling, grinding, and milling.One of the key highlights of [Company Name]'s tungsten carbide tools is their exceptional cutting-edge retention. Unlike conventional tools, which often need frequent sharpening, these tools possess remarkable wear resistance, extending their lifespan and reducing downtime significantly. This advantage allows businesses to optimize their operations and streamline their production processes.Additionally, the advanced composition of [Company Name]'s tungsten carbide tools provides increased heat resistance, allowing for higher operating speeds. This feature leads to faster production cycles and higher throughput, resulting in improved overall efficiency. Furthermore, the enhanced heat resistance decreases the risk of tool deformation, ensuring consistent and reliable performance over prolonged periods.The versatility of [Company Name]'s tungsten carbide tools enables them to cater to a wide range of industries, including automotive, aerospace, construction, and mining. From precision cutting tools used in the automotive industry to heavy-duty tools required for mining operations, [Company Name] offers a comprehensive selection to meet various industrial needs.In addition to their durability and reliability, [Company Name]'s tungsten carbide tools are also designed for ease of use and operator comfort. Ergonomics are considered during the tool design process, ensuring that workers can handle the tools efficiently and safely for prolonged periods.To meet diverse customer requirements, [Company Name] offers customization options for its tungsten carbide tools. The company's team of experienced engineers works closely with clients to understand their specific needs and develops tailor-made solutions. This personalized approach sets [Company Name] apart from its competitors, as it strives to deliver customer-centric products and services.Furthermore, [Company Name] maintains a robust distribution network, ensuring that its tungsten carbide tools are readily available to customers worldwide. Alongside providing high-quality tools, the company offers comprehensive technical support and after-sales services to ensure customer satisfaction at every stage.Speaking about the latest product line, [Name], [Company Name]'s spokesperson, highlighted the company's commitment to innovation and customer success. He stated, "We are excited to introduce our new range of tungsten carbide tools that reflect our dedication to providing cutting-edge solutions to our customers. Through continuous research and development, we have created tools that not only meet but exceed industry standards, enabling our clients to achieve enhanced productivity and efficiency."With its innovative range of tungsten carbide tools, [Company Name] is poised to revolutionize the industrial tooling landscape. As businesses increasingly recognize the importance of utilizing high-performance tools, [Company Name] stands ready to meet their needs, ensuring they stay ahead in today's competitive market.About [Company Name]:[Company Name] is a renowned manufacturer of industrial tools with a strong focus on innovation and customer satisfaction. With a global presence, the company serves diverse industries, delivering cutting-edge solutions and exceptional customer service. Through continuous research and development, [Company Name] aims to set new standards in the tool manufacturing industry.

Discover the Latest Advancements in Tungsten Carbide Molds

The tungsten carbide mold industry has been experiencing a wave of excellent growth in recent years. Tungsten carbide molds are utilized in a variety of applications, from industrial manufacturing and engineering to household products and automotive components. The exceptional hardness and toughness of tungsten carbide mold make it an outstanding material for producing complex shapes, intricate designs, and tight tolerances. The market for tungsten carbide mold (TCM) is increasing, and one company is making a significant impact in the area.{} is one leader in the tungsten carbide mold (TCM) domain. They specialize in precise and complex tungsten carbide mold technologies and have been providing world-class products and services for almost a decade. The firm focuses on designing and manufacturing high-precision molds for various industries, including electronics, automotive, aerospace, defense, medical, and tool & die. Their tungsten carbide mold products are highly regarded for their exceptional accuracy, durability, and performance.{}’s tungsten carbide molds are made utilizing the latest CNC machines, which ensure precise and consistent material removal. They employ various tungsten carbide grades and design configurations depending on the customer’s requirements, ensuring that their tungsten carbide molds achieve optimal performance and lifespan. The company's TCM products are long-lasting and can withstand harsh environments and high pressures encountered in various industrial applications.One of the hallmarks of {}'s TCM is its uniformity and accuracy. They use advanced measuring equipment, such as the CMM machine, to optimize the mold's dimensional accuracy. In addition, their process involves detailed inspections at various stages of production, ensuring that the end product adheres to the intended design specifications.The company's tungsten carbide mold products undergo various surface treatments to make them more wear-resistant than traditional mold materials. These treatments include nitriding, hard coating, and surface polishing. The surface treatments not only improve the mold's wear resistance but also enhance its performance, resulting in high-quality products.Another critical aspect of {}’s TCM is their extensive knowledge of tungsten carbide. They have been able to develop and enhance their tungsten carbide technology over the years, which has enabled them to provide specialized and personalized solutions for their customers. They can design customized molds that cater to the specific needs of their clients in various industries.Since {} began manufacturing tungsten carbide molds, they have remained committed to the environment, health, and safety. They have implemented various measures to ensure that their processes are environmentally friendly, reducing greenhouse gas emissions and minimizing industrial waste. The company adheres to stringent safety standards and continuously trains its employees on safety procedures to minimize workplace accidents.As a result of their outstanding products and service delivery, {} has built an excellent reputation in the tungsten carbide mold industry. They have received several accolades and awards, including the ISO9001:2015 and ROHS certification, among others. Their customer-centric approach and continuous investment in research and development have enabled them to thrive in the tungsten carbide mold market.In conclusion, the tungsten carbide mold industry is experiencing a steady and impressive growth rate due to the exceptional properties and performance of tungsten carbide. Companies like {} are leading the way by providing world-class products and services that cater to the specific needs of different industries. With their precision, uniformity, and accuracy in tungsten carbide mold production, combined with their deep knowledge of the material, it is expected that {} will continue to be a dominant force in the tungsten carbide mold market for years to come.

Carbide Nails: Revolutionary Die Technology Shaping the Future of Nail Production

Innovative Carbide Nail Making Die Revolutionizes Nail Manufacturing[Company Name], a leading manufacturer of cutting-edge industrial tools and equipment, has recently launched a revolutionary carbide nail making die. This advanced technology is set to transform the nail manufacturing industry, providing a superior solution that enhances efficiency, durability, and overall productivity.The carbide nail making die, developed by [Company Name]'s team of experienced engineers and knowledgeable researchers, is a ground-breaking innovation in the field. This cutting-edge product is designed to deliver unparalleled precision and quality in the production of nails, catering to the diverse needs of various industries worldwide.Traditionally, nail manufacturing has predominantly relied on conventional dies made of steel. However, these conventional steel dies have numerous limitations, including a limited lifespan and the need for frequent repairs and replacements. [Company Name]'s carbide nail making die aims to overcome these challenges by utilizing the exceptional properties of carbide materials.Carbide, a compound of carbon and metal, possesses remarkable toughness, hardness, and heat resistance. By harnessing the inherent benefits of carbide, [Company Name] has successfully developed an innovative die that offers extended life expectancy, reducing downtime and enhancing overall productivity. The durability of the carbide nail making die ensures consistent nail quality throughout the production process, minimizing the need for adjustments and repairs.Furthermore, the carbide nail making die provides enhanced precision and accuracy, resulting in nails with consistent dimensions, smooth finishes, and reduced defects. This improvement in quality not only satisfies the stringent requirements of industries such as construction, carpentry, and furniture manufacturing but also meets the growing demands of discerning consumers who seek high-quality products.Another key advantage of [Company Name]'s carbide nail making die is its exceptional resistance to wear and tear. The innovative design and fabrication process ensure that the die remains sharp and maintains its cutting edge for extended periods even when subjected to continuous stress. This significantly reduces downtime and increases production capacity, allowing manufacturers to meet tight deadlines more effectively.The introduction of the carbide nail making die by [Company Name] aligns seamlessly with their commitment to technological advancements and innovative solutions. Driven by a philosophy of providing the best tools for industrial processes, they continually invest in research and development to meet the evolving needs of their customers.As [Company Name] introduces this revolutionary product to the nail manufacturing industry, they aim to enhance competitiveness and productivity. By minimizing production costs and maximizing output efficiency, manufacturers can optimize their operations and ultimately deliver greater value to their clientele.The potential impact of [Company Name]'s carbide nail making die extends beyond the realms of industrial production. As the construction and manufacturing industries increasingly emphasize environmental sustainability, this innovative technology contributes to reducing waste by ensuring fewer defective nails and minimizing the usage of materials, ultimately reducing the environmental footprint.In conclusion, [Company Name]'s introduction of the carbide nail making die sets a new standard in the nail manufacturing industry. By harnessing the exceptional properties of carbide materials, this advanced technology enhances durability, precision, and overall productivity. As this ground-breaking innovation gains traction, manufacturers across various industries can look forward to optimizing their operations and meeting the demands of the modern market.

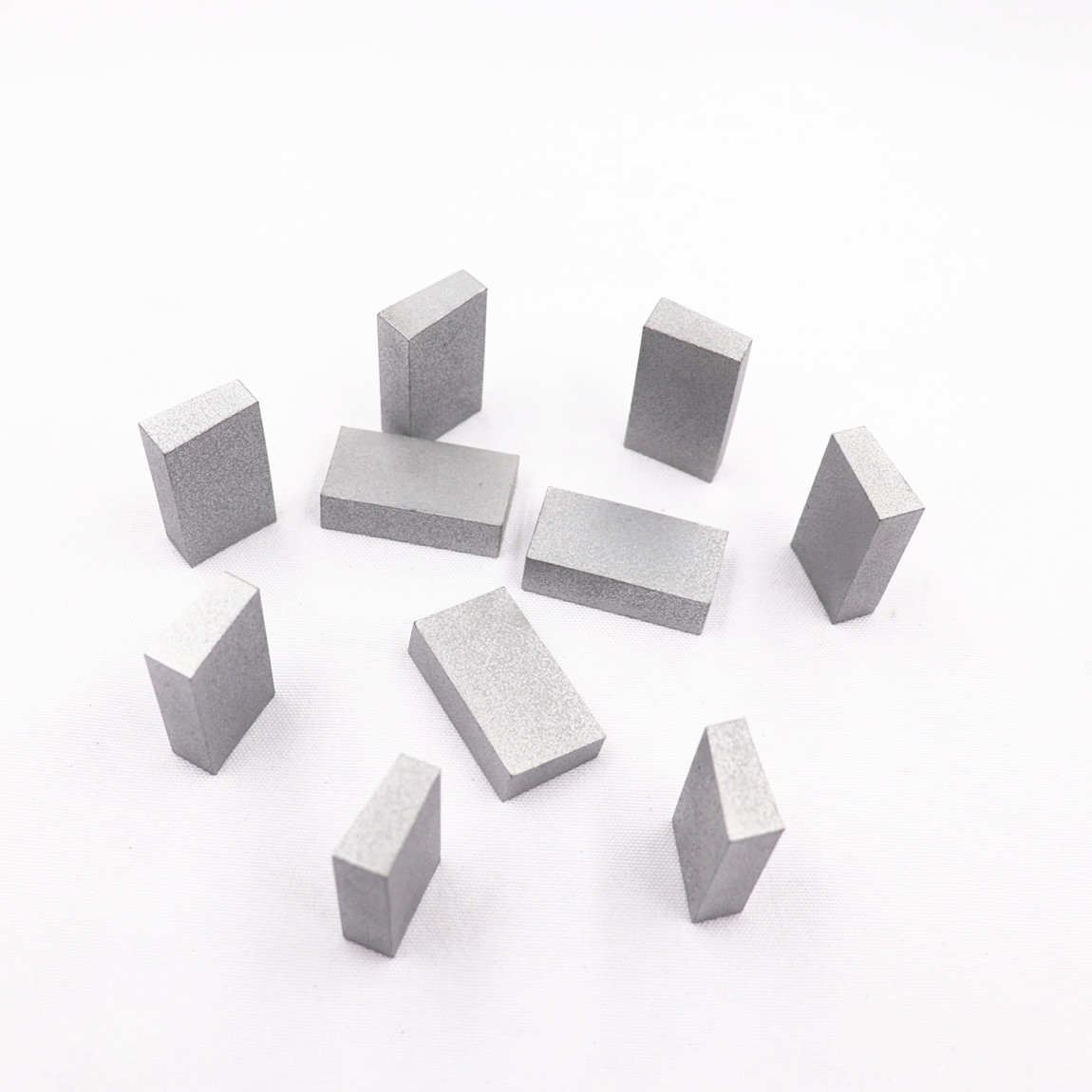

Discover the Benefits of Cemented Carbide Brazed Flakes for Your Industry

article about cemented carbide brazed flakes products.Cemented Carbide Brazed Flakes - The Future of Industrial Cutting ToolsCemented carbide brazed flakes are a new type of innovative product that has been introduced in the industrial cutting tool market in recent times. These products are used in the manufacturing of cutting tools, which are extensively used in the cutting, drilling, and grinding of various materials such as metals, wood, plastic, and ceramics. Cemented carbide brazed flakes are the future of industrial cutting tools because of their superior performance, durability, and cost-effectiveness.Cemented Carbide Brazed Flakes - The BasicsCemented carbide brazed flakes are made up of tungsten carbide particles that are sintered together through a process called brazing. The resulting structure is characterized by high hardness, toughness, and wear resistance properties. Cemented carbide brazed flakes are available in different shapes, sizes, and grades depending on the specific application. These products are commonly used in the construction of cutting tools such as drills, milling cutters, and saw blades.This innovative material has transformed the machining industry, particularly in the area of cutting, grinding, and drilling. It has emerged as one of the most popular materials for manufacturing cutting tools. The tungsten carbide particles are combined with a binder material such as cobalt or nickel to create the desired structure. The manufacturing process involves shaping the tungsten carbide particles, sintering them with the binder material and then brazing them onto the tool substrate. The result is a cemented carbide cutting tool that is highly durable, wear-resistant, and can deal with high machining speeds and extreme temperatures.Product Introduction{The brand name} is a well-known name in the manufacture of cemented carbide brazed flakes. They have been in the business for several years, and their products have gained wide acceptance in the market. Their cemented carbide brazed flakes are made from high-quality tungsten carbide particles that are sintered and brazed to create cutting tools with excellent cutting ability and long tool life. Their product is well-known for its superior quality and excellent performance in various machining applications.{The brand name}’s cemented carbide brazed flakes are suitable for use in various industries, including aerospace, automotive, medical, and general engineering. They offer a wide range of grades and sizes to accommodate different machining needs. Their product line includes bored bar, end mills, inserts, threaded inserts, and solid carbide drills, among others.Performance and BenefitsCemented carbide brazed flakes offer several performance benefits, including high hardness, toughness, and wear resistance. These properties make them suitable for machining materials that are difficult to cut, such as hardened steels, aerospace alloys, and composite materials. Cemented carbide brazed flakes also offer consistent performance throughout the life of the cutting tool, resulting in more reliable and consistent machining.Another advantage of cemented carbide brazed flakes is their superior heat resistance. They can withstand high temperatures without losing their cutting ability, making them ideal for high-speed machining applications. This means that cutting tools made from cemented carbide brazed flakes can handle the heat generated during the machining process without damaging the tool or the workpiece.Cost-effectiveness is also a significant benefit of using cemented carbide brazed flakes. While the initial cost of these cutting tools may be higher than traditional tools, their superior performance and long tool life make them more cost-effective in the long run. This means that manufacturers save money on tooling costs and reduce downtime and tool changeover, resulting in increased productivity and profitability.ConclusionCemented carbide brazed flakes are a game-changer in the industrial cutting tool market. Their superior performance, durability, and cost-effectiveness make them the future of machining. {The brand name} is at the forefront of this innovation, offering high-quality cemented carbide brazed flakes to meet the machining needs of various industries. With their consistent performance, heat resistance, and cost-effectiveness, it is no surprise that cemented carbide brazed flakes continue to gain popularity and acceptance in the market.

Discover the Latest Innovation in Tungsten Carbide Plungers for Enhanced Performance

Tungsten Carbide Plungers Revolutionize Industrial ApplicationsIn today's rapidly evolving industrial landscape, businesses are constantly seeking innovative solutions to enhance efficiency, durability, and cost-effectiveness. As a leader in cutting-edge technology, Company X has consistently pushed the boundaries of possibilities, revolutionizing the way industries operate. Their latest breakthrough comes in the form of Tungsten Carbide Plungers, a game-changing advancement that is transforming various industrial applications.Company X has been at the forefront of research and development in the field of materials engineering for decades. Understanding the demand for high-performance components, they identified a critical need for durable plungers in numerous industries such as oil and gas, chemical processing, and automotive manufacturing. Traditional plungers, though effective, had inherent limitations that hindered optimal performance and longevity.Recognizing this opportunity, Company X dedicated substantial resources to develop an advanced plunger that would overcome these challenges. After extensive research and testing, they introduced Tungsten Carbide Plungers, which have quickly emerged as game-changers in the industry. These plungers have gained recognition not only for their durability but also for their exceptional performance under extreme conditions.Tungsten Carbide Plungers are made from one of the hardest materials known to man, tungsten carbide, combined with other elements to maximize their strength and resilience. This unique composition results in plungers that offer extraordinary resistance to wear, corrosion, and extreme temperature variations. This unparalleled durability allows for longer operational lifetimes, reduced maintenance costs, and increased overall productivity.One of the key advantages of Tungsten Carbide Plungers is their ability to withstand harsh chemicals and abrasive fluids. In industries where corrosive substances are prevalent, conventional plungers often deteriorate quickly, leading to expensive replacements and downtime. Company X's Tungsten Carbide Plungers, however, can tolerate even the harshest chemical environments, ensuring uninterrupted operations and significant cost savings.Another notable feature of Tungsten Carbide Plungers is their exceptional performance in high-pressure applications. Industries such as oil and gas extraction and chemical processing demand components that can withstand extreme pressures without compromising efficiency or safety. The robust nature of Tungsten Carbide Plungers allows them to handle immense pressures, ensuring smooth operations even in the most demanding environments.Furthermore, Tungsten Carbide Plungers possess outstanding thermal stability, making them ideal for applications involving extreme temperature fluctuations. Whether it is automotive manufacturing or industrial furnaces, these plungers maintain their integrity and performance, even in conditions where conventional alternatives would fail.Company X has revolutionized the market with Tungsten Carbide Plungers, setting new standards for durability and reliability in various industries. By addressing the limitations of traditional plungers, they have provided businesses with a cost-effective solution that enhances operational efficiency, reduces downtime, and minimizes maintenance costs.In addition to their superior product offering, Company X has also focused on providing excellent customer service. Their dedicated team of professionals works closely with customers, understanding their unique requirements and offering customized solutions. With a commitment to quality and a client-centric approach, Company X has become a trusted partner for numerous businesses, ensuring optimal performance and lasting success.In conclusion, Tungsten Carbide Plungers from Company X have transformed industrial applications by delivering unmatched durability, resistance, and performance. These plungers have revolutionized various sectors, including oil and gas, chemical processing, and automotive manufacturing. Through their unwavering commitment to innovation and customer satisfaction, Company X continues to reshape the industrial landscape, empowering businesses to achieve greater efficiency and profitability.