Cold Heading Dies: What You Need to Know

By:Admin

Cold heading dies are an essential component in the process of cold forming metal, specifically in the production of fasteners and other complex metal parts. The quality of the dies directly affects the accuracy and durability of the final product, making them a crucial element in the manufacturing process.

{Company Name}'s new line of cold heading dies is designed to meet the evolving needs of the industry, featuring advanced materials and cutting-edge technology to ensure superior performance and extended lifespan. The company's dedication to research and development is evident in the innovative design and precision engineering of these dies, which are poised to set a new benchmark for quality and reliability.

In addition to their technical capabilities, {Company Name} has also prioritized the usability and versatility of their cold heading dies. By offering a range of customization options, the company ensures that their products can cater to the specific requirements of different manufacturing processes. This flexibility is a direct response to the increasingly diverse and specialized needs of the industry, demonstrating {Company Name}'s commitment to delivering solutions that align with the unique demands of their clients.

Furthermore, {Company Name} has established a reputation for providing comprehensive support to their customers, and the launch of their new line of cold heading dies is no exception. In addition to the high-quality products themselves, the company offers technical assistance, maintenance services, and training programs to help clients optimize the performance of the dies and maximize their operational efficiency.

The introduction of the new line of cold heading dies further solidifies {Company Name}'s position as a leading provider of industrial solutions, and reflects their ongoing dedication to driving innovation and progress in the manufacturing sector. The company's forward-thinking approach, combined with their extensive expertise, makes them a trusted partner for businesses seeking to stay ahead in a competitive market.

As the global demand for high-quality metal components continues to grow, the release of {Company Name}'s new line of cold heading dies comes at a pivotal time. By equipping manufacturers with the tools they need to meet and exceed industry standards, the company is poised to make a significant impact on the future of metal forming and manufacturing.

In conclusion, {Company Name}'s new line of cold heading dies represents a significant advancement in the field of metal forming technology. With their unwavering commitment to quality, innovation, and customer satisfaction, the company continues to be a driving force in shaping the future of industrial manufacturing. As businesses around the world seek to elevate their production capabilities, {Company Name} stands ready to empower them with the tools they need to succeed.

Company News & Blog

Tungsten Carbide Brazing Tips: A Comprehensive Guide for Effective Bonding

Tungsten Carbide Brazing Tips Revolutionize Welding IndustryAs the demand for high-quality and durable welding solutions continues to rise, manufacturers worldwide are constantly striving to develop state-of-the-art products that can meet the ever-evolving needs of the industry. In line with this goal, an industry-leading company introduces its innovative Tungsten Carbide Brazing Tips, a game-changer that is set to revolutionize the welding industry.Welders are no strangers to the challenges associated with finding the perfect brazing tips. The traditional options available often suffer from issues such as poor durability, reduced performance, and high replacement costs. However, this company has taken a leap forward by developing brazing tips made from Tungsten Carbide, a cutting-edge material that promises to overcome these challenges.Tungsten Carbide is a remarkable compound known for its exceptional hardness, superior durability, and resistance to wear and tear. Its ability to withstand high temperatures and provide a consistently strong performance makes it an ideal choice for brazing tips, enabling welders to achieve precise and efficient results with ease.One of the key features of this innovative product is its longevity. Unlike traditional brazing tips that wear out quickly and require frequent replacement, Tungsten Carbide Brazing Tips are built to last. This offers significant cost savings for welders as they can enjoy prolonged usage without worrying about the added expenses of constantly purchasing new tips.Additionally, the outstanding performance of these brazing tips ensures greater efficiency and improved results. The hardness of Tungsten Carbide enhances its resistance to wear and tear, allowing welders to work on a wide range of materials without compromising the quality of their work. This product's exceptional durability also contributes to reducing downtime, as welders can continue their work uninterrupted for longer periods.Furthermore, the Tungsten Carbide Brazing Tips offer enhanced precision and accuracy during welding. The high melting point and excellent heat resistance properties of Tungsten Carbide minimize tip deformation, resulting in better control and finer welds. This newfound precision empowers welders to complete their projects with meticulousness and expertise, thus satisfying even the most demanding industry standards.The company behind this groundbreaking product has built a reputation for innovative solutions and unparalleled expertise in the welding industry. Their commitment to research and development has enabled them to stay ahead of the curve, continuously introducing cutting-edge products that redefine industry standards.With a dedicated team of experts, the company ensures that every aspect of their product development process is meticulously planned and executed. From the selection of premium raw materials to the utilization of state-of-the-art manufacturing techniques, they leave no stone unturned in their pursuit of excellence. Their stringent quality control measures guarantee that each Tungsten Carbide Brazing Tip is built to last, providing welders with the utmost reliability and performance.Looking ahead, the introduction of Tungsten Carbide Brazing Tips is poised to have a significant impact on the welding industry. This breakthrough product not only addresses the common issues faced by welders but also raises the bar for what can be achieved through cutting-edge technology and innovation.Welders around the world can now take advantage of these remarkable tips to enhance their performance, improve their efficiency, and deliver impeccable results. The Tungsten Carbide Brazing Tips are set to become an indispensable component in every welder's toolkit, serving as a testament to the strive for excellence within the welding industry.

High-Quality Carbide Wear Parts for Industrial Applications

Carbide Wear Parts has been making waves in the manufacturing industry with their innovative and high-quality products. The company has been a leading supplier of wear parts for a wide range of industries, such as mining, construction, and oil and gas. With a strong focus on research and development, Carbide Wear Parts has been able to consistently deliver cutting-edge solutions to its customers.Founded in 2005, Carbide Wear Parts quickly established itself as a reliable and reputable source for wear parts. The company's commitment to excellence and dedication to customer satisfaction has allowed it to build a strong reputation in the industry. As a result, Carbide Wear Parts has become a preferred supplier for many leading manufacturers and companies around the world.One of the key factors that sets Carbide Wear Parts apart from its competitors is its use of advanced materials and manufacturing techniques. The company leverages the latest advancements in carbide technology to produce wear parts that offer superior performance and durability. This has made Carbide Wear Parts a trusted partner for companies looking for reliable solutions to their wear part needs.Carbide Wear Parts prides itself on its ability to provide custom solutions to its customers. The company understands that each industry and application has unique requirements, and it is committed to working closely with its clients to develop tailored solutions that meet their specific needs. This personalized approach has helped Carbide Wear Parts build strong relationships with its customers, and has contributed to its continued growth and success.In addition to its focus on quality and customer satisfaction, Carbide Wear Parts is also dedicated to sustainability and environmental responsibility. The company is committed to minimizing its environmental impact and has implemented a number of initiatives to reduce waste and pollution in its manufacturing process. By prioritizing sustainability, Carbide Wear Parts is able to provide its customers with environmentally friendly products that meet their performance requirements.The success of Carbide Wear Parts can be attributed to its talented team of engineers and industry experts. The company has assembled a team of highly skilled professionals who are passionate about delivering innovative solutions to their customers. With their expertise and dedication, Carbide Wear Parts has been able to stay ahead of the competition and continue to push the boundaries of what is possible in the wear parts industry.Looking to the future, Carbide Wear Parts is poised for continued growth and success. The company is constantly looking for new ways to innovate and improve its products, and is committed to staying at the forefront of wear part technology. With its strong foundation of quality, innovation, and customer satisfaction, Carbide Wear Parts is well positioned to remain a leader in the industry for years to come.In conclusion, Carbide Wear Parts has established itself as a trusted and reliable supplier of wear parts for a wide range of industries. Through its focus on quality, innovation, and customer satisfaction, the company has been able to build strong relationships with its customers and maintain a leading position in the industry. With its commitment to sustainability and ongoing dedication to excellence, Carbide Wear Parts is well positioned for continued success in the years to come.

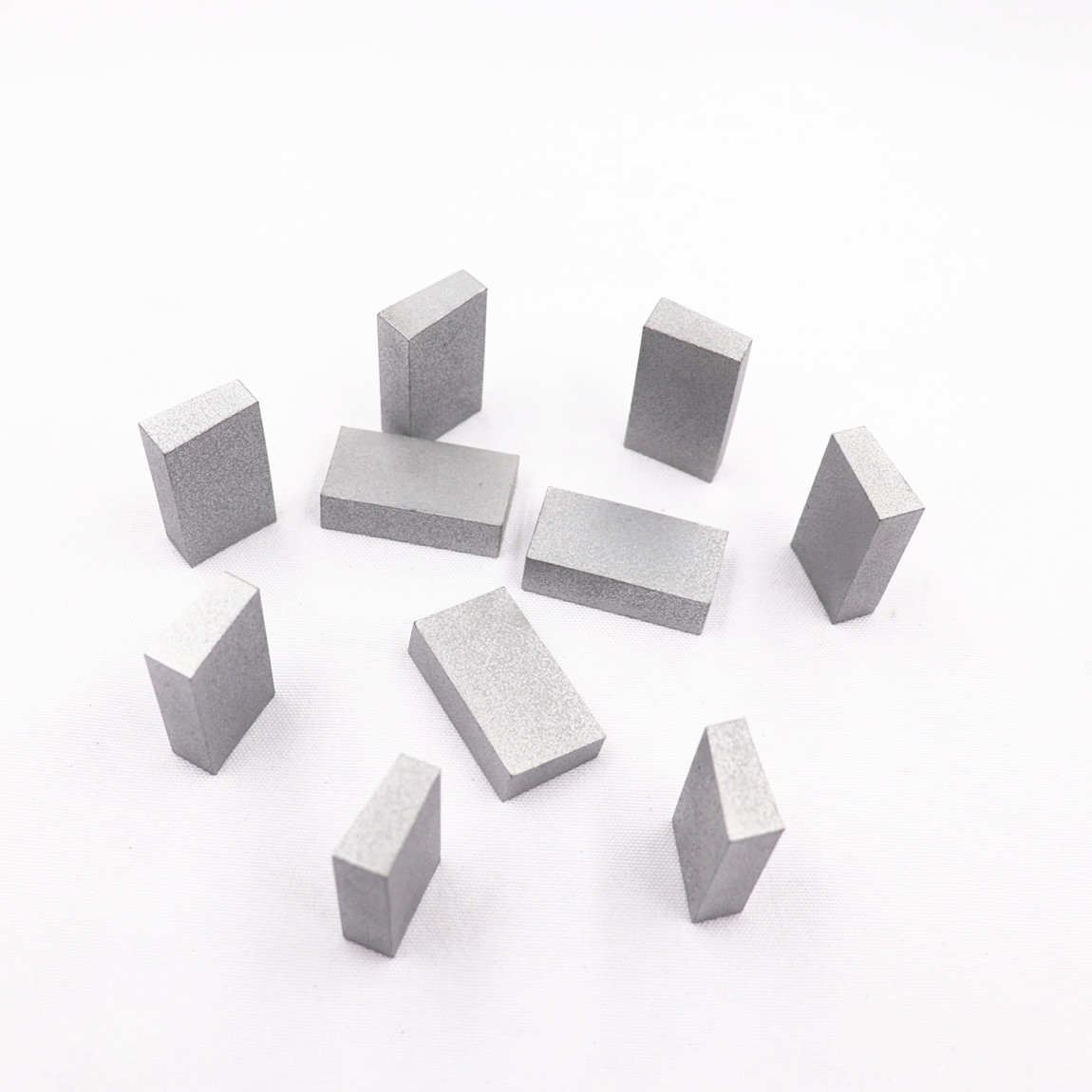

High-Quality Tungsten Carbide Blocks: A Strong and Durable Option

Tungsten Carbide Block, a revolutionary new product developed by (Company Name), is set to revolutionize the industry with its unparalleled durability and longevity. The company, renowned for its innovative and cutting-edge solutions, has once again raised the bar with the introduction of Tungsten Carbide Block, a game-changing advancement in engineering materials.Tungsten Carbide Block is crafted using the highest quality tungsten carbide, a material known for its exceptional hardness and wear resistance. This superior material is combined with advanced manufacturing processes to create a product that is not only incredibly durable but also highly versatile.The applications for Tungsten Carbide Block are endless, ranging from cutting tools and wear parts to mining equipment and agricultural machinery. The product's unique combination of hardness and toughness makes it ideal for withstanding the most extreme conditions and heavy-duty industrial applications.(Company Name) has a long-standing reputation for delivering high-quality, reliable products, and Tungsten Carbide Block is no exception. With extensive research and development, the company has engineered a product that exceeds industry standards and outperforms traditional materials in terms of longevity and performance.One of the key features of Tungsten Carbide Block is its exceptional resistance to wear and erosion. This makes it an ideal choice for cutting and drilling applications where prolonged use can lead to rapid deterioration of conventional materials. With Tungsten Carbide Block, users can expect extended tool life and reduced downtime, ultimately resulting in cost savings and improved productivity.In addition to its superior wear resistance, Tungsten Carbide Block also offers excellent corrosion resistance, making it suitable for use in harsh environments and corrosive materials. This attribute further extends the product's lifespan, making it a long-term, cost-effective solution for a wide range of industries.(Company Name) takes great pride in its commitment to sustainability and environmental responsibility. Tungsten Carbide Block is manufactured using eco-friendly processes and materials, ensuring that it meets the company's high standards for sustainability. Furthermore, the product's long lifespan and durability contribute to reduced waste and environmental impact, aligning with (Company Name)'s vision for a more sustainable future.The introduction of Tungsten Carbide Block further solidifies (Company Name)'s position as a leader in the industry, known for its innovative solutions and exceptional product quality. By staying ahead of the curve and continually pushing the boundaries of engineering materials, the company has set a new standard for durability and performance.(Company Name) is dedicated to providing its customers with the highest quality products and unparalleled service. With the launch of Tungsten Carbide Block, the company aims to meet the evolving needs of industries that require durable, long-lasting materials for their most demanding applications.As (Company Name) continues to expand its product offerings and enhance its capabilities, Tungsten Carbide Block stands out as a testament to the company's unwavering commitment to excellence and innovation. With its exceptional performance and unmatched durability, this revolutionary new product is set to make a significant impact in a wide range of industries, setting a new standard for engineering materials worldwide.

The Role of Cemented Carbide in the Manufacturing Industry

Cemented Carbide, also known as solid carbide, is a composite material widely used in the manufacturing industry for its exceptional hardness and resistance to wear and corrosion. It is made up of tungsten carbide particles embedded in a matrix of cobalt or nickel, resulting in a material that is extremely strong and durable. The properties of cemented carbide make it an ideal choice for a wide range of applications, including cutting tools, wear parts, and components for the mining, construction, and oil and gas industries. Its ability to withstand high temperatures and maintain sharp cutting edges even under extreme conditions has made it indispensable in the production of tools and machinery. One of the leading manufacturers of cemented carbide products is {Company}. With over 50 years of experience in the industry, {Company} has established itself as a trusted supplier of high-quality carbide tools and components. The company's commitment to excellence and continuous innovation has enabled it to gain a strong foothold in the global market, serving customers in various sectors such as aerospace, automotive, and metalworking. {Company} offers a diverse range of cemented carbide products, including inserts, end mills, drills, and wear parts, all of which are designed to deliver superior performance and long-lasting durability. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that its products meet the highest standards and exceed customer expectations. In addition to its extensive product line, {Company} also provides custom solutions and technical support to help customers optimize their production processes and achieve maximum efficiency. Its team of skilled engineers and experts is dedicated to collaborating with clients to develop tailored solutions that address specific needs and challenges. Furthermore, {Company} is committed to sustainability and environmental responsibility in its operations. The company emphasizes the use of recycled materials and efficient production methods to minimize its environmental impact. By promoting eco-friendly practices and investing in sustainable technologies, {Company} aims to contribute to a greener and more sustainable future for the industry. In recent news, {Company} has announced the launch of a new line of advanced cemented carbide products that are set to revolutionize the manufacturing industry. These innovative products are engineered to deliver enhanced performance, productivity, and cost-efficiency, catering to the evolving needs of the market. With cutting-edge designs and superior material compositions, these new products are expected to set new benchmarks for quality and reliability in cemented carbide technology. The launch of these new products reaffirms {Company}'s position as a leader in the cemented carbide industry, showcasing its unwavering commitment to pushing the boundaries of innovation and delivering value to customers. The company's dedication to research and development, coupled with its deep understanding of market trends and customer requirements, has enabled it to stay ahead of the curve and anticipate the evolving demands of the industry. As {Company} continues to expand its global footprint, it remains focused on providing exceptional products and services to its customers worldwide. Through its extensive network of distributors and partners, the company is able to reach and support a diverse customer base, ensuring that its cemented carbide solutions are readily available and easily accessible. Looking ahead, {Company} is poised to continue its growth and success in the cemented carbide industry, driven by its relentless pursuit of excellence and customer satisfaction. With a strong foundation built on quality, innovation, and integrity, the company is well-positioned to shape the future of cemented carbide technology and set new benchmarks for the industry.

Tungsten Carbide Dies: An Essential Tool for Precision and Durability

Title: Tungsten Carbide Dies Revolutionize Manufacturing IndustryIntroduction:With the rapid advancement in manufacturing technologies, the demand for high-quality, precision-made components has surged in various sectors. As a world leader in the production of Tungsten Carbide Dies, [Company Name] has been at the forefront of this industry, revolutionizing manufacturing processes and achieving exceptional results. This article will explore the characteristics and applications of Tungsten Carbide Dies, as well as highlight the exceptional contributions of [Company Name] in this field.1. The Unparalleled Performance of Tungsten Carbide Dies:Tungsten Carbide Dies have gained prominence due to their exceptional hardness, wear resistance, and robustness. Composed of a combination of tungsten and carbon, these dies offer unmatched strength and durability. This unique composition ensures that the dies can withstand extreme pressures and high temperatures without succumbing to premature wear and tear. As a result, Tungsten Carbide Dies provide an extended service life, significantly reducing downtime and enhancing productivity.2. Applications of Tungsten Carbide Dies:Tungsten Carbide Dies find applications in a wide range of industries, including automotive, aerospace, electronics, and more. In the automotive sector, these dies are utilized for cold heading and forming metal components in engines, transmissions, and brakes. They are also crucial in the production of fasteners, such as screws, bolts, and rivets. The aerospace industry extensively relies on Tungsten Carbide Dies for precision extrusion, wire drawing, and tube forming, ensuring consistent quality and reliability. Furthermore, the electronics industry employs these dies for intricate wire bonding processes, enabling the manufacture of miniature electronic components with exceptional precision and quality.3. The Exemplary Contributions of [Company Name] in Tungsten Carbide Dies Manufacturing:[Company Name] has been an industry leader in the manufacturing of Tungsten Carbide Dies, setting new standards of excellence and reliability. With decades of experience, the company has developed advanced manufacturing processes, utilizing state-of-the-art machinery and cutting-edge technology. [Company Name]'s team of highly skilled engineers and technicians apply rigorous quality control measures at every stage of production to ensure the finest products that meet or exceed customer expectations.4. Continuous Innovation and Research and Development:[Company Name] has consistently invested in research and development activities to stay ahead of the curve and introduce groundbreaking technologies in the Tungsten Carbide Dies manufacturing industry. By collaborating with leading institutions and industry experts, the company ensures the continuous improvement of their product range, adapting to the evolving needs of their customers. This commitment to innovation has positioned [Company Name] as a trusted partner and manufacturer of choice for many global companies.5. Contributing to Sustainable Manufacturing:Apart from their exceptional performance, Tungsten Carbide Dies also contribute to sustainable manufacturing practices. The long-lasting nature of these dies reduces the need for frequent replacements, minimizing waste and resource consumption. Additionally, the high precision and quality achieved with Tungsten Carbide Dies lead to a reduction in manufacturing defects, further reducing material waste and energy consumption while enhancing overall operational efficiency.Conclusion:The advent of Tungsten Carbide Dies has undoubtedly revolutionized the manufacturing industry, offering unparalleled strength, durability, and precision. [Company Name] has played a critical role in this transformation, providing exceptional products and spearheading innovation in the field. With their continuous commitment to excellence, [Company Name] ensures that the manufacturing industry can achieve new levels of quality, efficiency, and sustainable production.

Discover the Superiority of Tungsten Carbide Wire Drawing Dies in the News

[Company name], a leading manufacturer of tungsten carbide wire drawing dies, is revolutionizing the wire drawing industry with its innovative and high-performance products. With a strong commitment to quality, reliability, and customer satisfaction, the company has become a trusted name in the industry.Tungsten carbide wire drawing dies are crucial components used in the manufacturing process of various wires. These dies are known for their exceptional hardness, wear resistance, and durability, making them ideal for drawing high-quality wires of different diameters. [Company name]'s extensive lineup of tungsten carbide wire drawing dies caters to the diverse needs of various industries, including automotive, electronics, telecommunications, and construction.The company's extensive experience and expertise in the field of manufacturing wire drawing dies have enabled them to develop cutting-edge solutions that meet the rigorous demands of the industry. Their team of engineers and technicians is dedicated to continuous research and development, ensuring that their products are at the forefront of technological advancements.One of the key features of [Company name]'s tungsten carbide wire drawing dies is their superior surface finish, which ensures smooth wire drawing operations. The dies are meticulously engineered to minimize surface defects and reduce wire breakage, resulting in improved production efficiency and cost-effectiveness.Moreover, [Company name] understands that every customer has unique requirements and specifications. Therefore, they offer customized solutions tailored to the specific needs of each client. Whether it is a specific wire shape, size, or coating requirement, the company's experts work closely with the clients to design and manufacture dies that meet their exact specifications.In addition to their commitment to quality, [Company name]'s commitment to environmental sustainability is commendable. They adhere to strict environmental standards throughout their manufacturing processes, ensuring minimal impact on the environment. Their sustainable practices and responsible approach have earned them certifications and recognition from various regulatory bodies.Furthermore, customer satisfaction is at the core of [Company name]'s business ethos. The company strives to provide exceptional service and support to its customers, ensuring that their needs are met promptly and efficiently. Their dedicated customer service team is readily available to address any queries or concerns, ensuring a seamless experience for their clients.To stay ahead in a highly competitive market, [Company name] also invests in cutting-edge technology and machinery. Their state-of-the-art manufacturing facilities are equipped with the latest equipment, enabling them to produce wire drawing dies with unmatched precision and quality.As a testament to their commitment to excellence, [Company name] has earned a stellar reputation in the industry. Their products are known for their outstanding performance, durability, and long service life. Countless satisfied customers testify to the superior quality and reliability of [Company name]'s tungsten carbide wire drawing dies.With their unwavering dedication to innovation, quality, and customer satisfaction, [Company name] continues to be a leader in the tungsten carbide wire drawing dies industry. The company's relentless pursuit of excellence and commitment to meeting the evolving needs of its customers ensure that it will remain at the forefront of the industry for years to come.As demand for high-quality wires continues to grow across various industries, [Company name]'s tungsten carbide wire drawing dies are set to play a crucial role in meeting this demand. With their superior performance, unmatched quality, and exceptional customer support, [Company name] is poised to shape the future of the wire drawing industry.

Top Quality Carbide Dies for Precision Manufacturing – Everything You Need to Know

Carbide Dies: A Key Component in Manufacturing ExcellenceCarbide dies have become an essential component in the manufacturing industry, with their ability to produce high-quality, precise and durable components. These dies are used in a wide range of applications, including the production of fasteners, wire and tube drawing, extrusion, and many more. One company that has established itself as a leader in the production of carbide dies is {}.{} is a renowned company in the field of carbide die manufacturing, with a long-standing reputation for delivering high-quality products to its customers. The company has been in the business for over 30 years, and during this time, it has continuously focused on innovation and excellence in its products.The use of carbide dies has become increasingly popular in the manufacturing industry due to their exceptional wear resistance and high thermal conductivity. These qualities make carbide dies ideal for high-speed and high-volume manufacturing processes, where durability and precision are crucial. {} has capitalized on these attributes to develop a wide range of carbide dies that cater to the diverse needs of its customers.One of the key areas where carbide dies have made a significant impact is in the production of fasteners. {} has developed a range of carbide dies specifically tailored for the fastener industry, which has allowed manufacturers to improve their productivity and produce high-quality fasteners with tight tolerances. The superior wear resistance of carbide dies ensures a longer die life, reducing the downtime required for die changes and ultimately improving the overall efficiency of the manufacturing process.In addition to the fastener industry, {} has also made a mark in the wire and tube drawing sector. The company's carbide dies have enabled manufacturers to achieve improved surface finish, reduced die wear, and higher production speeds. This has translated into significant cost savings and enhanced product quality for its customers.The extrusion industry is another area where carbide dies have proven to be invaluable. {} has developed a range of carbide dies that are suitable for various extrusion processes, including aluminum, copper, and brass extrusion. These dies are designed to withstand the high pressures and temperatures involved in the extrusion process, ensuring consistent product quality and die longevity.{}'s commitment to quality and innovation has been a driving force behind its success in the carbide die manufacturing industry. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that its carbide dies meet the highest standards of precision and durability. Moreover, its team of experienced engineers and technicians are constantly working to develop new and improved carbide die solutions to meet the evolving needs of its customers.The global manufacturing industry continues to evolve, and the demand for high-quality, precision components is ever-growing. Carbide dies have become an indispensable tool in meeting these demands, and {} is at the forefront of delivering top-notch carbide die solutions to manufacturers around the world. The company's unwavering commitment to excellence and customer satisfaction has solidified its position as a trusted partner for carbide die manufacturing, and it continues to set new benchmarks for quality and innovation in the industry.

Discover the Efficiency and Durability of Cutting Tooth for Carbide Materials

Title: Innovative Carbide Cutting Tooth Revolutionizes Cutting Efficiency in Various IndustriesIntroduction:In today's rapidly evolving industries, the demand for efficient cutting tools that can withstand heavy workloads and offer superior performance has never been higher. Recognizing this pressing need, {Company Name}, a leading manufacturer of industrial tools, has introduced a groundbreaking Carbide Cutting Tooth. With its exceptional cutting prowess and durability, this advanced tool is set to transform the cutting processes across several sectors, including construction, mining, and forestry.Section 1: Evolution of Cutting ToolsThe field of cutting tools has experienced several evolutionary milestones, driven by the constant pursuit of improved performance and efficiency. Traditional cutting tools made of high-speed steel (HSS) have gradually been replaced by carbide-tipped alternatives due to their enhanced durability and wear resistance. Carbide, being a composite material of tungsten carbide particles embedded within a metallic binder, offers remarkable hardness and toughness necessary for heavy-duty operations.Section 2: Introducing the Innovative Carbide Cutting Tooth{Company Name} has utilized advanced research and development techniques to create a highly efficient Carbide Cutting Tooth that exceeds expectations. This innovative tool boasts a unique design, combining a trapezoidal shape with deep gullets, allowing for efficient chip evacuation during cutting operations, thus minimizing downtime and maximizing productivity.Section 3: Unparalleled Durability and LongevityOne of the key advantages of the Carbide Cutting Tooth is its unparalleled durability. The cutting edges incorporate high-quality carbide inserts, ensuring exceptional wear resistance even when subjected to extreme cutting conditions. This durability translates into reduced tool replacement and maintenance costs, ultimately boosting overall operational efficiency.Section 4: Enhanced Cutting PerformanceThe Carbide Cutting Tooth is engineered to deliver enhanced cutting performance across various materials. Whether cutting through concrete, wood, or metal, the advanced tooth design ensures precise cuts with reduced vibrations and increased stability. This cutting-edge technology facilitates smoother operations, resulting in superior finishing and reduced material wastage.Section 5: Application across IndustriesThe versatile Carbide Cutting Tooth finds applications in numerous industries. In construction, it offers significant advantages in road milling, trenching, and concrete demolition. In the mining sector, the tool exhibits exceptional performance in rock cutting and tunneling operations. Moreover, it proves valuable in the forestry industry for various applications, such as land clearing, tree felling, and branch trimming. Its widespread usage across these sectors demonstrates its adaptability and effectiveness.Section 6: Environmental Impact and Safety FeaturesIn line with the company's commitment to sustainability, the Carbide Cutting Tooth incorporates various safety features to minimize its environmental impact. High-efficiency chip evacuation mechanisms prevent dust and debris accumulation, reducing the release of harmful particles into the environment. Additionally, the cutting tooth design promotes operator safety by minimizing kickback and vibration, ensuring a secure working environment.Section 7: Market Outlook and ConclusionThe introduction of the innovative Carbide Cutting Tooth by {Company Name} is set to revolutionize the cutting tool market. Its superior cutting performance, exceptional durability, and versatility across industries make it the go-to choice for professionals seeking efficiency and reliability in their operations. With its potential to boost productivity, reduce costs, and improve overall cutting efficiency, this advanced tool is destined to be a game-changer for the global industry.In conclusion, the remarkable Carbide Cutting Tooth developed by {Company Name} signifies a significant leap in cutting tool technology. Its intelligent design, durability, and enhanced cutting performance are poised to transform cutting processes in construction, mining, and forestry sectors. As the demand for efficient cutting tools continues to soar, the industry is set to embrace this innovative solution that promises unparalleled efficiency, reduced costs, and improved overall outcomes.

High-Quality Cemented Carbide Block Sheet for Exceptional Durability and Performance

Cemented Carbide Block Sheet: A High-Quality Material for Industrial ApplicationsIn many industrial applications, materials with high strength, hardness, and wear resistance are crucial for achieving the desired performance and efficiency. Cemented carbide, also known as tungsten carbide, is one such material that has been widely used in cutting tools, mining equipment, drilling tools, wear parts, and other high-demanding applications. A recent innovation in the cemented carbide industry is the development of cemented carbide block sheets, which offer even greater versatility and flexibility in design and manufacturing.Cemented carbide block sheets are made of finely ground tungsten carbide particles, which are mixed with a small amount of metallic binder, such as cobalt or nickel. The mixture is then compacted into a block shape and sintered at high temperature and pressure. The result is a dense and homogeneous material that exhibits outstanding properties, including high hardness, strength, toughness, and resistance to wear, corrosion, and deformation.One of the main advantages of cemented carbide block sheets is their flexibility in size, shape, and thickness. Unlike traditional carbide blanks, which are limited in their dimensions and require additional machining to achieve the desired shape and size, block sheets can be easily cut, drilled, milled, and ground to the exact specifications needed for a particular application. This allows for more efficient and cost-effective production of complex and customized parts, without sacrificing quality or performance.Another benefit of using cemented carbide block sheets is their versatility in applications. Due to their high strength and wear resistance, they are ideal for use in harsh and demanding environments, such as mining, construction, oil and gas, and metalworking. They can be used for cutting, drilling, grinding, milling, punching, and shaping a wide range of materials, including steel, iron, aluminum, copper, and alloys. They are also used in wear parts, such as nozzles, blades, seals, and dies, where their durability and long service life are crucial.Cemented carbide block sheets are also environmentally friendly, as they can be recycled and reused in new products. Tungsten carbide is a rare and valuable material that is in high demand in many industries, and its recycling can help reduce the extraction and processing of new materials. Moreover, the manufacturing of block sheets requires less energy and resources than traditional carbide blanks, as it involves fewer steps and less waste.One company that has been at the forefront of the development and production of cemented carbide block sheets is {} (name removed for privacy). Founded in {}, {} has been providing innovative and high-quality carbide products to the global market for over years. {} specializes in the design, production, and distribution of cemented carbide block sheets and other carbide products, such as rods, inserts, tips, and blanks, for various industries.{} uses advanced technology and equipment to manufacture its carbide products, ensuring consistent quality and performance. Its cemented carbide block sheets are made of premium-grade tungsten carbide powders and high-purity metallic binders, which are carefully selected and mixed to achieve the desired properties. The block sheets are available in various grades, sizes, and geometries, and can be customized to meet specific customer requirements.{}'s cemented carbide block sheets have been widely used in cutting tools, mining equipment, construction tools, and wear parts, among others. They have been proven to deliver superior performance and durability, even in extreme conditions. Moreover, {} offers technical support and consultancy services to help customers optimize their applications and achieve the best results.In conclusion, cemented carbide block sheets are a valuable and versatile material for many industrial applications, offering high strength, toughness, wear resistance, and flexibility in design and manufacturing. {} (name removed for privacy) is a leading supplier of high-quality cemented carbide block sheets and other carbide products, catering to the diverse needs of customers worldwide. With its commitment to quality, innovation, and customer satisfaction, {} is poised to continue its growth and success in the carbide industry.

Cemented Carbide Pallets: Durable and Long-Lasting Options for Your Industrial Needs

Cemented Carbide Pallets Revolutionize Material Handling: A Game-Changer for {Company Name}In an era where efficiency and productivity are key factors in the success of a business, the innovative use of advanced materials is opening up new possibilities for companies seeking to streamline their operations. One such breakthrough in the field of material handling is the development and implementation of cemented carbide pallets, a game-changer for businesses working with heavy loads and large-scale logistics. Leading the charge in adopting this revolutionary technology is {Company Name}, which has successfully integrated cemented carbide pallets into its operations, setting a new standard for efficiency and durability in material handling.Cemented carbide, also known as solid carbide or tungsten carbide, is a composite material that consists of a mixture of carbide particles, typically tungsten carbide, and a binder metal, usually cobalt. Known for its exceptional hardness, wear resistance, and toughness, cemented carbide has long been utilized in a variety of industrial applications, including cutting tools, mining equipment, and wear parts. However, its use in material handling pallets represents a significant innovation in the industry, offering a range of benefits that traditional materials such as wood or plastic simply cannot match.{Company Name} has recognized the potential of cemented carbide pallets to transform its material handling operations, and has made a significant investment in integrating this cutting-edge technology into its facilities. The decision to adopt cemented carbide pallets was driven by the company's commitment to maximizing efficiency, minimizing downtime, and reducing maintenance costs. By harnessing the unparalleled durability and wear resistance of cemented carbide, {Company Name} has been able to significantly extend the lifespan of its pallets, minimizing the need for frequent replacements and ensuring a smooth and uninterrupted flow of materials throughout its operations.The use of cemented carbide pallets has also had a ripple effect on other aspects of {Company Name}'s material handling processes. With their exceptional strength and load-bearing capacity, cemented carbide pallets have allowed the company to optimize its storage and transportation of goods, enabling the safe and secure handling of even the heaviest and most cumbersome loads. This has not only improved the overall efficiency of the company's logistics operations but has also enhanced workplace safety by reducing the risk of pallet failure and the potential for accidents related to material handling.Furthermore, the introduction of cemented carbide pallets has had a positive environmental impact, aligning with {Company Name}'s commitment to sustainability. Unlike traditional pallet materials such as wood or plastic, cemented carbide is highly resistant to degradation and damage, resulting in a significant reduction in the generation of waste from pallet disposal. Additionally, the extended lifespan of cemented carbide pallets has led to a reduction in the overall consumption of materials, contributing to a more sustainable and eco-friendly approach to material handling.In a highly competitive market where every advantage counts, the adoption of cemented carbide pallets has positioned {Company Name} at the forefront of innovation in material handling. By leveraging the unmatched durability and performance of cemented carbide, the company has not only enhanced its operational efficiency but has also set a new standard for reliability and sustainability in its industry. This forward-thinking approach is a testament to {Company Name}'s dedication to embracing cutting-edge technologies and pushing the boundaries of what is possible in material handling.Looking ahead, the successful integration of cemented carbide pallets into {Company Name}'s operations serves as a clear example of how forward-thinking companies can harness the power of advanced materials to drive innovation and achieve new levels of efficiency and sustainability. As other businesses take note of the remarkable impact that cemented carbide pallets have had on {Company Name}'s operations, it is likely that this revolutionary technology will continue to gain traction across a wide range of industries, ultimately reshaping the landscape of material handling in the years to come.