High-Quality Tungsten Carbide Manufacturing: Everything You Need to Know

By:Admin

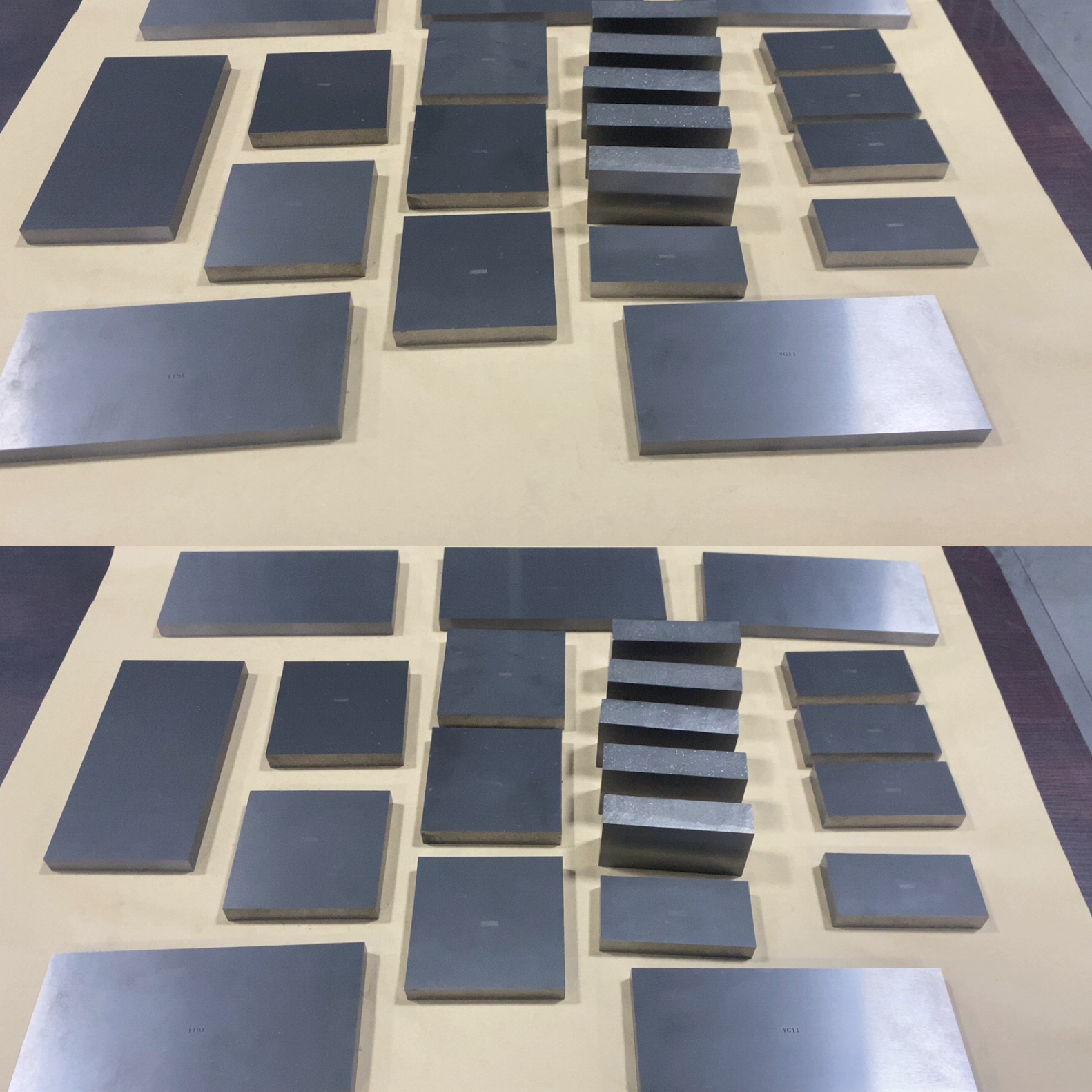

Founded in {}, {} has over {} years of experience in the manufacture of tungsten carbide. Their state-of-the-art facilities and advanced technology allow them to produce a wide range of tungsten carbide products, including cutting tools, wear parts, and components for a variety of industrial applications. They are committed to quality and precision, and their products are known for their reliability and long-lasting performance.

One of the key factors that sets {} apart from other companies in the industry is their emphasis on research and development. They have a team of dedicated scientists and engineers who are constantly working to improve their processes and develop new and innovative tungsten carbide products. This commitment to innovation has allowed them to stay ahead of the competition and meet the evolving needs of their customers.

In addition to their focus on research and development, {} is also committed to sustainability and environmental responsibility. They have implemented rigorous environmental standards in their manufacturing processes and are constantly seeking ways to reduce their environmental impact. This commitment to sustainability has not only earned them the trust and respect of their customers, but has also positioned them as a leader in the industry.

Furthermore, {} has a strong emphasis on customer service and satisfaction. They work closely with their customers to understand their specific needs and provide customized solutions to meet those needs. Whether it's developing a unique tungsten carbide product or providing technical support and expertise, {} is dedicated to ensuring that their customers receive the highest level of service and support.

With a focus on quality, innovation, sustainability, and customer service, {} has earned a reputation as a trusted and reliable supplier of tungsten carbide products. Their dedication to excellence has made them a preferred partner for companies across a wide range of industries, and their products are used in some of the most demanding and high-performance applications.

Looking to the future, {} is poised to continue leading the way in tungsten carbide manufacture. With their ongoing commitment to research and development, sustainability, and customer service, they are well-positioned to meet the evolving needs of the industry and continue providing high-quality tungsten carbide products for years to come. As the demand for advanced materials continues to grow, companies like {} will play a crucial role in driving innovation and shaping the future of the industry.

Company News & Blog

Discover the Durability of Wear Resistant Tungsten Carbide Parts

Tungsten Carbide Wear Resistant Parts: Revolutionizing Industrial MachineryIn the fast-paced world of industrial manufacturing, the search for durable and high-performance components is never-ending. One material that has gained substantial recognition in recent years is Tungsten Carbide, a unique compound renowned for its wear-resistant properties. This exceptional material has revolutionized the way industrial machinery functions and has become an indispensable asset for companies striving for efficient operations.Tungsten Carbide wear-resistant parts have become an integral part of various industries, including mining, construction, oil and gas, and manufacturing. These parts, meticulously engineered using Tungsten Carbide, have demonstrated outstanding performance in even the harshest operating conditions.As a company at the forefront of technology and innovation in the manufacturing realm, {Company Name} has made significant strides in producing and supplying high-quality Tungsten Carbide wear-resistant parts globally. Their unwavering commitment to delivering exceptional performance and meeting the ever-evolving needs of industries has garnered them a solid reputation among their clientele.Established in {year}, {Company Name} has a rich history of expertise in the field of manufacturing cutting-edge wear-resistant parts. With a team of skilled engineers and state-of-the-art manufacturing facilities, the company remains dedicated to producing parts that surpass industry standards.The success of {Company Name} lies in their holistic approach towards developing Tungsten Carbide parts. From the design process to the final product, every step is meticulously carried out to ensure uncompromising quality. Through continuous research and development efforts, the company stays at the forefront of advancements in Tungsten Carbide technology.One of the key strengths of {Company Name} is their ability to provide tailor-made solutions for customers' unique requirements. Whether it is a large-scale mining operation or a small-scale manufacturing plant, {Company Name} has the expertise to deliver custom-engineered wear-resistant parts that maximize efficiency and prolong equipment lifespan.The inherent properties of Tungsten Carbide make it the material of choice for wear-resistant parts. This compound exhibits exceptional hardness, surpassing that of steel by several magnitudes. Tungsten Carbide parts, therefore, excel in environments with extreme abrasion, erosion, and impact.By utilizing Tungsten Carbide wear-resistant parts, industries can significantly reduce maintenance costs and downtime. The robust nature of these parts ensures extended equipment lifespan, enabling companies to meet production targets efficiently. This translates into substantial cost savings and improved profitability for businesses.Furthermore, Tungsten Carbide wear-resistant parts offer exceptional thermal stability, making them suitable for applications where high temperatures are present. The unique combination of hardness and heat resistance allows {Company Name}'s parts to endure extreme working conditions, where alternative materials may fail.In addition to their superior durability, Tungsten Carbide wear-resistant parts from {Company Name} are also known for their exceptional precision. The company utilizes cutting-edge manufacturing techniques, including computer-aided design (CAD) and computer numerical control (CNC) machining. These techniques ensure precise dimensions and tight tolerances, resulting in seamless integration with existing machinery.{Company Name} provides an extensive range of Tungsten Carbide wear-resistant parts, including nozzles, valves, bushings, cutting tools, and mining wear parts. Their diverse portfolio caters to a wide range of applications across various industries, making them a one-stop shop for all wear-resistant requirements.In conclusion, Tungsten Carbide wear-resistant parts have revolutionized industrial machinery, offering unmatched durability and performance. As a pioneer in the manufacturing industry, {Company Name} has capitalized on the potential of this exceptional material and consistently delivers high-quality parts. Their dedication to innovation, customization, and precision has positioned them as a leader in the market. With {Company Name}'s products, industries can enhance their operational efficiency, reduce costs, and ultimately achieve greater success.

High-quality Tungsten Carbide Pellets for Industrial Applications

Title: Cutting-Edge Tungsten Carbide Pellets Revolutionizing IndustriesIntroductionIn an era driven by technological advancements and innovative breakthroughs, {Company Name} emerges as a leading provider of high-performance tungsten carbide pellets. These remarkable pellets, market-tested and now made available for various industries, are set to revolutionize manufacturing processes. With exceptional durability and cutting-edge characteristics, these tungsten carbide pellets are poised to enhance productivity and efficiency across multiple sectors.Unleashing the Power of Tungsten Carbide{Tungsten carbide pellets} are engineered to set new standards, particularly in metalworking applications. Composed of a carefully balanced combination of tungsten and carbon, these pellets exhibit unparalleled hardness, exceptional strength, and impressive wear resistance. These features make tungsten carbide pellets a favored choice for various industries including construction, mining, aerospace, and manufacturing.Combining the strength of tungsten and the carbon's hardness, {Company Name}'s tungsten carbide pellets are significantly superior to conventional cutting tools. The pellets' exceptional hardness and durability make them ideal for machining applications that involve tough materials like steel and cast iron. This superior abrasive resistance enables manufacturers to achieve higher precision, extended tool life, and reduced downtime, ultimately boosting productivity.A Versatile Solution for Multiple Industries{Company Name}'s tungsten carbide pellets cater to a wide range of industries, from metalworking to drilling and mining. Their advanced formulation ensures the pellets can withstand extreme conditions, making them perfect for cutting, grinding, drilling, and milling applications.In the construction industry, tungsten carbide pellets provide a remarkable solution for cutting through reinforced concrete and asphalt. Their exceptional wear resistance and longevity make them an invaluable asset for construction companies seeking efficiency and durability in their projects.The mining industry also benefits greatly from these pellets. The outstanding hardness and superior cutting performance of tungsten carbide make it the go-to choice for drilling tools. Mining companies can now maximize their productivity and reduce operational costs by using {Company Name}'s tungsten carbide pellets.Additionally, the aerospace sector can achieve precision and reliability with the implementation of tungsten carbide pellets. Advanced machining processes require tools that can withstand extreme temperatures and pressures while ensuring precise cuts. With these pellets, {Company Name} empowers aerospace manufacturers to meet these demands and deliver high-quality components for aircraft and spacecraft.Staying Ahead through InnovationOne of the key differentiators of {Company Name} lies in their continuous dedication to innovation. Consistently investing in research and development, they strive to improve their tungsten carbide pellets to suit the ever-changing needs of industries. The company collaborates with industry experts, employing cutting-edge technologies and manufacturing processes to maintain their market leadership.{Company Name} also emphasizes their commitment to environmental sustainability. Through their advanced production techniques, they ensure minimal waste and energy consumption during manufacturing. This dedication to eco-friendliness resonates with their environmentally conscious clientele.ConclusionWith their exceptional hardness, unrivaled wear resistance, and superior cutting performance, {Company Name}'s tungsten carbide pellets are set to transform industries worldwide. From metalworking to aerospace, these pellets offer a versatile and high-performance solution for various applications. With continuous innovation and a commitment to sustainability, {Company Name} stands at the forefront of providing the manufacturing sector with the latest advances in tungsten carbide technology.

High-Quality Tungsten Carbide Manufacturing: Everything You Need to Know

Tungsten carbide is a versatile material that is used in a wide range of industries, from aerospace to mining to manufacturing. It is known for its hardness, strength, and resistance to wear and corrosion, making it an ideal material for a variety of applications. One company that has been at the forefront of tungsten carbide manufacture is {}. With a long history of innovation and expertise in the industry, they have established themselves as a leading supplier of high-quality tungsten carbide products.Founded in {}, {} has over {} years of experience in the manufacture of tungsten carbide. Their state-of-the-art facilities and advanced technology allow them to produce a wide range of tungsten carbide products, including cutting tools, wear parts, and components for a variety of industrial applications. They are committed to quality and precision, and their products are known for their reliability and long-lasting performance.One of the key factors that sets {} apart from other companies in the industry is their emphasis on research and development. They have a team of dedicated scientists and engineers who are constantly working to improve their processes and develop new and innovative tungsten carbide products. This commitment to innovation has allowed them to stay ahead of the competition and meet the evolving needs of their customers.In addition to their focus on research and development, {} is also committed to sustainability and environmental responsibility. They have implemented rigorous environmental standards in their manufacturing processes and are constantly seeking ways to reduce their environmental impact. This commitment to sustainability has not only earned them the trust and respect of their customers, but has also positioned them as a leader in the industry.Furthermore, {} has a strong emphasis on customer service and satisfaction. They work closely with their customers to understand their specific needs and provide customized solutions to meet those needs. Whether it's developing a unique tungsten carbide product or providing technical support and expertise, {} is dedicated to ensuring that their customers receive the highest level of service and support.With a focus on quality, innovation, sustainability, and customer service, {} has earned a reputation as a trusted and reliable supplier of tungsten carbide products. Their dedication to excellence has made them a preferred partner for companies across a wide range of industries, and their products are used in some of the most demanding and high-performance applications.Looking to the future, {} is poised to continue leading the way in tungsten carbide manufacture. With their ongoing commitment to research and development, sustainability, and customer service, they are well-positioned to meet the evolving needs of the industry and continue providing high-quality tungsten carbide products for years to come. As the demand for advanced materials continues to grow, companies like {} will play a crucial role in driving innovation and shaping the future of the industry.

Discover the Power and Reliability of Tungsten Carbide Cold Heading Dies

[Headline: YG8 Tungsten Carbide Cold Heading Dies Now Available for Enhanced Cold Forging Processes][Subtitle: The Perfect Solution for Efficient and High-Quality Cold Heading Operations][Date][Location]In the world of metalworking, one essential component for efficient and high-quality cold forging processes is the selection of suitable tools. Tungsten carbide cold heading dies have emerged as the industry-standard for their exceptional hardness, wear resistance, and durability. Among the various brands available in the market, the YG8 Tungsten Carbide Cold Heading Dies have gained immense popularity, providing manufacturers with an optimal solution to meet their forging needs.Tungsten carbide is a composite material that consists of tungsten carbide particles held together by a binder. This unique synergy gives rise to a material that possesses remarkable strength and hardness, making it ideal for the demanding conditions encountered during cold heading operations. The YG8 brand, known for its excellent quality and reliability, has become a go-to choice for many manufacturers worldwide.With the increasing demand for precision-formed metal parts across various industries such as automotive, aerospace, and construction, companies are striving to achieve higher efficiency and quality in their manufacturing processes. Cold heading, a critical technique used to shape metal blanks into finished products, requires the utilization of high-performance tools to ensure accurate and consistent results. The YG8 Tungsten Carbide Cold Heading Dies offer manufacturers a competitive edge by maximizing productivity and minimizing costly downtime.The YG8 brand stands out for its exceptional wear resistance, allowing for prolonged use without compromising precision. These cold heading dies are engineered to withstand the extreme pressures and friction encountered during the cold forging process, increasing their service life and reducing the frequency of tool replacement. This durability translates into cost savings and less disruption to the production line, ultimately boosting the overall efficiency of the manufacturing process.In addition to durability, the YG8 Tungsten Carbide Cold Heading Dies also deliver superior performance in terms of dimensional accuracy and surface finish. The high hardness and toughness of tungsten carbide ensure that the dies can maintain their shape and size over extended periods, resulting in consistent and precise forming of metal blanks. With tighter tolerances and improved surface finishes, manufacturers can eliminate the need for additional machining operations, streamlining their production processes and achieving faster turnaround times.Furthermore, the YG8 brand prides itself on delivering customization options to cater to specific cold heading requirements. Whether it is specialized and intricate shapes or unique dimensions, YG8 provides tailored solutions to meet diverse customer needs. This flexibility allows manufacturers to fully optimize their cold heading processes, producing parts that adhere to the highest standards of quality and functionality.To ensure the utmost product reliability, YG8 Tungsten Carbide Cold Heading Dies undergo stringent quality control measures during the manufacturing process. This includes rigorous testing for hardness, toughness, and dimensional accuracy. By adhering to the highest quality standards, YG8 guarantees that only top-notch products reach the hands of its customers, enabling them to achieve unparalleled results in their cold forging operations.As the demand for precision metal components continues to rise, the importance of selecting the right tools and materials cannot be overstated. The YG8 Tungsten Carbide Cold Heading Dies stand as a testament to the commitment of providing manufacturers with innovative and high-quality solutions. With their exceptional durability, accuracy, and customization options, the YG8 brand is poised to revolutionize the cold forging industry, enabling manufacturers to stay ahead of the competition and meet the evolving needs of their customers.

The Ultimate Guide to Tungsten Carbide Sleeves: Everything You Need to Know

Tungsten Carbide Sleeves: Revolutionizing the Industrial SectorIn today's rapidly evolving industrial landscape, companies are constantly in search of innovative solutions that can enhance their operational efficiency, mitigate risks, and reduce costs. One such groundbreaking solution making waves in the industry is the Tungsten Carbide Sleeve. Renowned for its remarkable durability and versatility, Tungsten Carbide Sleeves are playing a pivotal role in revolutionizing multiple industrial sectors.Tungsten Carbide Sleeves, manufactured using cutting-edge technology, are designed to withstand extreme working conditions. The high hardness, wear resistance, and excellent thermal stability of this material make it an ideal choice for a wide range of applications, including oil and gas drilling, mining, metalworking, and automotive manufacturing.The emergence of Tungsten Carbide Sleeves has been a game-changer for the oil and gas industry. Drilling operations in this sector often encounter highly abrasive and corrosive environments, where equipment failure can lead to catastrophic consequences. Tungsten Carbide Sleeves provide the necessary protection, extending the lifespan of drilling tools and reducing costly downtime. Their exceptional hardness and wear resistance enable these sleeves to endure relentless drilling, resulting in enhanced drilling efficiency and productivity.Similarly, the mining industry has also reaped the benefits of Tungsten Carbide Sleeves. Mining operations involve handling abrasive materials, which can cause rapid wear and tear on equipment. By implementing Tungsten Carbide Sleeves, mining companies have experienced a significant reduction in maintenance costs and improved equipment performance. These sleeves not only enhance the lifespan of mining tools but also contribute to increased mining productivity.The metalworking sector, which encompasses diverse industries such as aerospace, automotive, and machining, has also embraced Tungsten Carbide Sleeves as a game-changing solution. The exceptional hardness and wear resistance of these sleeves make them an excellent choice for cutting and machining applications. They ensure precision and accuracy, resulting in high-quality finished products. Additionally, Tungsten Carbide Sleeves provide thermal stability, reducing the risk of thermal deformation during high-speed machining processes. This has enabled companies to enhance their manufacturing capabilities and meet the ever-increasing demands of their customers.Automotive manufacturing, a sector constantly striving for innovation and efficiency, has also witnessed the transformative power of Tungsten Carbide Sleeves. The high wear resistance of these sleeves has prolonged the life of critical automotive components, such as engine valves and pistons. This has not only reduced the need for frequent replacements but also contributed to improved engine performance and fuel efficiency. Moreover, Tungsten Carbide Sleeves ensure precision and quality during the manufacturing process, contributing to the overall reliability and safety of vehicles.One company at the forefront of Tungsten Carbide Sleeve manufacturing is . With a commitment to innovation and a passion for excellence, has become a trusted name in the industry. Their state-of-the-art manufacturing facility, combined with a team of highly skilled engineers, ensures superior quality and performance of their Tungsten Carbide Sleeves. utilizes advanced technologies and stringent quality control processes to produce Tungsten Carbide Sleeves that exceed industry standards. Their sleeves undergo rigorous testing to ensure durability, exceptional wear resistance, and compatibility with various applications. With a focus on customer satisfaction, offers customized solutions to meet specific requirements, regardless of the industry.As the demand for high-performance materials continues to grow, Tungsten Carbide Sleeves have emerged as a game-changing solution across multiple industrial sectors. With their exceptional durability, wear resistance, and thermal stability, these sleeves are revolutionizing the way businesses operate. As companies strive for efficiency, cost reduction, and innovation, Tungsten Carbide Sleeves prove to be an indispensable asset in achieving a competitive edge in the global market.In conclusion, the emergence of Tungsten Carbide Sleeves has revolutionized the industrial sector by providing exceptional durability, wear resistance, and thermal stability. Their diverse applications in oil and gas drilling, mining, metalworking, and automotive manufacturing have paved the way for increased operational efficiency, reduced costs, and improved productivity. As leads the way in Tungsten Carbide Sleeve manufacturing, businesses can harness the transformative power of these sleeves to stay at the forefront of innovation and achieve sustainable growth.

Tungsten Carbide: The Key to Strong and Durable Products

Title: The Versatility of Tungsten Carbide Unleashed: A Game-Changer in Industrial ApplicationsIntroduction:In today's rapidly evolving industrial landscape, where durability, strength, and versatility are paramount, Tungsten Carbide emerges as an indispensable material. Widely recognized for its outstanding performance in various applications, this ground-breaking compound has revolutionized industries such as mining, drilling, manufacturing, and more. With its unique properties and exceptional adaptability, Tungsten Carbide has become the go-to choice for companies seeking cutting-edge solutions. This news article aims to shed light on the numerous advantages of Tungsten Carbide while exploring its growing significance as an industry influencer.Tungsten Carbide: The Powerhouse Compound:Tungsten Carbide, distinct for its hardness and impressive resistance to wear, is a compound composed of equal parts of tungsten and carbon atoms. Renowned for its exceptional properties, this material is the epitome of strength, making it ideal for applications that demand high performance. By combining tungsten and carbon, an ultra-tough alloy is produced, which exudes remarkable strength, rigidity, and resilience. These exceptional qualities have cemented Tungsten Carbide's status as a game-changer in various industries.Diving Deeper: Understanding the Properties of Tungsten Carbide:At its core, Tungsten Carbide's unique properties truly set it apart from other materials. Firstly, its impressive hardness makes Tungsten Carbide almost as hard as diamond, ensuring exceptional resistance to abrasions, impacts, and wear. This key feature allows tools and machinery incorporating Tungsten Carbide to endure harsh environments, extending their lifespan and improving overall productivity.Secondly, Tungsten Carbide boasts an impressively high melting point, surpassing 2,800°C (5,432°F). This attribute proves vital in applications where extreme heat and pressure are present, such as drilling in the oil and gas industry. The remarkable stability and resistance exhibited by Tungsten Carbide enable it to perform flawlessly under the most challenging conditions.Moreover, Tungsten Carbide's versatility is exemplified through its ability to be molded into various shapes and sizes to suit different applications. This adaptability allows for intricate designs and customized solutions, catering to diverse industry requirements. Additionally, Tungsten Carbide exhibits exceptional resistance to corrosion, oxidation, and chemical damage, making it an invaluable material in harsh environments.Industrial Applications: Where Tungsten Carbide Reigns Supreme:1. Mining and Drilling: Tungsten Carbide's hardness and resistance make it an ideal choice for mining tools, drill bits, and inserts. The compound's ability to withstand extreme wear in the harsh conditions of underground mining enhances productivity while reducing maintenance costs.2. Manufacturing and Cutting Tools: Tungsten Carbide's exceptional hardness and toughness lend itself well to cutting tools, such as blades, inserts, and precision instruments. The durability of these tools ensures consistent, high-quality outputs in manufacturing processes, enabling companies to achieve remarkable efficiency and cost-effectiveness.3. Wear Parts and Gasket Sealing: In industries where abrasive materials and extreme pressure are encountered, Tungsten Carbide remains a popular choice for wear parts such as nozzles, valve seats, and pump components. Its resistance to wear and wear-related damages ensures extended lifespan and uninterrupted operation of crucial equipment.Conclusion:Tungsten Carbide has evolved into an irreplaceable material, epitomizing strength, durability, and adaptability in various industrial applications. With its exceptional hardness, high melting point, and resistance to wear and corrosion, it has become the hallmark of reliability in mining, manufacturing, drilling, and more. The ever-growing prominence of Tungsten Carbide reflects its ability to deliver enhanced productivity, reduced maintenance costs, and unmatched precision, ultimately driving innovation within industries across the globe. As technology advances, Tungsten Carbide's versatility will continue to inspire further breakthroughs, solidifying its position as a true game-changer in the industrial world.

Cemented Carbide Rods: A Comprehensive Guide to Enhance Your Industrial Applications

Cemented Carbide Rods: Revolutionizing the Manufacturing IndustryIn today's competitive manufacturing industry, companies are constantly seeking innovative solutions to enhance their production processes and increase overall efficiency. One such groundbreaking innovation is the development and application of cemented carbide rods. These remarkable tools have revolutionized various sectors, providing incredible strength and durability while minimizing wear and tear, ultimately reducing a company's maintenance costs.Cemented carbide rods, often referred to as tungsten carbide rods, are widely used in metalworking, woodworking, and other industries that rely on precision cutting and shaping. This innovative material is the result of combining tungsten carbide, a ceramic compound, with a binding metallic cobalt or nickel. The combination offers exceptional hardness and resistance to heat, providing an ideal material for manufacturing tools that can withstand extreme conditions.One company at the forefront of cemented carbide rod production is (company name), a renowned leader in the manufacturing and distribution of industrial cutting tools and equipment. With years of experience and a commitment to quality, (company name) has become a trusted partner for businesses seeking reliable and long-lasting cemented carbide rods.Initially founded in (year), (company name) has evolved into a global player, catering to a wide range of industries including automotive, aerospace, and construction. The company's cemented carbide rods have gained significant popularity due to their exceptional performance and reliability, enabling businesses to improve their productivity and stay ahead in today's competitive market.One of the key advantages of cemented carbide rods is their impressive hardness. With a hardness rating of up to 90 HRA (Rockwell Hardness A), these rods outperform traditional steel and high-speed steel tools, ensuring efficient cutting and shaping processes even under the most demanding circumstances. This tremendous durability translates into longer tool life, reducing the frequency of tool replacement and ultimately saving manufacturing companies significant costs.Moreover, cemented carbide rods exhibit remarkable resistance to wear and tear. The binding metallic cobalt or nickel acts as a protective layer, preventing the rods from deteriorating or losing their sharpness over time. This characteristic allows (company name)'s cemented carbide rods to maintain their cutting edge, reducing the need for frequent re-sharpening or replacement. As a result, businesses using these rods experience enhanced and uninterrupted production cycles, increasing their overall efficiency.Another critical feature of cemented carbide rods is their exceptional resistance to heat. The combination of tungsten carbide and metallic binders results in a material capable of withstanding high temperatures, making it suitable for operations involving intense heat generation. Traditional tools often degrade under such conditions, leading to productivity slowdowns and potential damage to the workpiece. In contrast, cemented carbide rods offer superior heat resistance, ensuring uninterrupted workflow and consistent precision even in the most challenging environments.In addition to the superior physical properties of cemented carbide rods, (company name) constantly focuses on research and development to optimize their performance. By utilizing cutting-edge technology and collaborating with experts in the field, the company consistently introduces innovative designs and improvements to its product lineup. This commitment to innovation allows (company name) to stay ahead of the competition and provide its customers with state-of-the-art cemented carbide rods that meet the evolving needs of the manufacturing industry.Furthermore, (company name) recognizes the importance of providing comprehensive technical support and guidance to its customers. The company's team of experts ensures that clients understand the correct usage and maintenance procedures associated with cemented carbide rods, thus maximizing their longevity and effectiveness. This dedication to excellent customer service has established (company name) as a trusted and reliable partner in the manufacturing sector.In conclusion, cemented carbide rods have transformed the manufacturing industry, empowering businesses to achieve higher levels of productivity and efficiency. With exceptional hardness, resistance to wear and tear, and heat resistance, these robust tools offer unmatched durability and reliability. As a leading provider of cemented carbide rods, (company name) continues to shape the industry by delivering cutting-edge solutions and unwavering customer support. As manufacturing continuously evolves, these tools will undoubtedly play a central role in driving innovation and progress.

Cemented Carbide Becomes Crucial Component in Cutting Tools

Yungshin Metal Industries Co., Ltd. produces YG8 cemented carbide, a high-quality material used in a wide range of industries around the world. This advanced material is known for its strong durability and resistance to wear and tear, making it a top choice for manufacturing and construction professionals.YG8 cemented carbide is made from a combination of tungsten carbide and cobalt, providing it with its unique properties. This material is commonly used in drill bits, cutting tools, and wear-resistant parts, among other applications. Its high density and hardness make it ideal for use in harsh environments, where other materials might not hold up.Yungshin Metal Industries Co., Ltd. has been producing high-quality YG8 cemented carbide for over 25 years. The company has become a trusted name in the advanced materials industry, thanks to its commitment to quality and customer satisfaction. Yungshin Metal Industries Co., Ltd. has a team of experienced professionals who work to produce and deliver YG8 cemented carbide to customers around the world.One of the key advantages of YG8 cemented carbide is its ability to withstand high temperatures. This material can handle extreme heat without losing its hardness or shape, making it ideal for use in applications like cutting tools and wear-resistant parts. YG8 cemented carbide is also resistant to corrosion, giving it a long lifespan even in harsh environments.In addition to its technical properties, YG8 cemented carbide is also a cost-effective option for manufacturers and construction professionals. This material is widely used in the production of drilling equipment, mining machinery, and cutting tools, among other applications. Its long lifespan and durability mean that companies can save money on replacement parts and equipment, while also reducing downtime and improving productivity.Yungshin Metal Industries Co., Ltd. has a strong commitment to sustainability and ethical business practices. The company uses environmentally-friendly production methods and sources its raw materials from reputable suppliers. Yungshin Metal Industries Co., Ltd. also follows strict quality control measures to ensure that all products meet or exceed industry standards.YG8 cemented carbide is just one of the high-quality materials produced by Yungshin Metal Industries Co., Ltd. The company also produces a range of other materials, including tungsten carbide, ceramic, and titanium products. These advanced materials are used in a variety of industries, from aerospace and defense to medical devices and electronics.In conclusion, YG8 cemented carbide is a top choice for manufacturing and construction professionals around the world. This high-quality material is known for its strength, durability, and resistance to wear and tear, making it ideal for use in a wide range of applications. Yungshin Metal Industries Co., Ltd. has over 25 years of experience producing YG8 cemented carbide, along with a range of other advanced materials. Its commitment to quality, sustainability, and customer satisfaction has made it a trusted name in the industry.

High-Quality Polished Tungsten Carbide Roller for Industrial Applications

Polished Tungsten Carbide Roller Revolutionizing Manufacturing IndustryIn recent years, the manufacturing industry has seen numerous advancements in technology and materials that have greatly improved productivity and efficiency. One such advancement is the development of the Polished Tungsten Carbide Roller, a superior tool that has revolutionized the manufacturing process in various industries.The Polished Tungsten Carbide Roller is a product of innovation and expertise developed by a leading company in the manufacturing industry. [Company Name] has been a pioneer in the development and production of high-quality industrial tools and materials for over two decades. With a strong focus on research and development, the company has been able to create cutting-edge products that meet the evolving needs of the manufacturing sector.The Polished Tungsten Carbide Roller is a remarkable example of [Company Name]'s commitment to excellence. Tungsten carbide is a unique material known for its exceptional hardness and durability, making it ideal for use in industrial applications. The company's rollers are meticulously crafted and polished to perfection, ensuring outstanding performance and longevity in various manufacturing processes.One of the key advantages of the Polished Tungsten Carbide Roller is its exceptional wear resistance. The polished surface significantly reduces friction and wear, leading to a longer service life and reduced maintenance costs. This makes it an ideal choice for applications that involve high-speed and high-pressure environments, such as in the production of metal sheets, paper, and plastic films.Furthermore, the precise engineering of the Polished Tungsten Carbide Roller results in superior dimensional accuracy and surface finish. This enables manufacturers to achieve higher levels of precision and consistency in their end products, ultimately leading to improved product quality and customer satisfaction.Moreover, the Polished Tungsten Carbide Roller offers excellent corrosion resistance, making it suitable for use in harsh and corrosive environments. This ensures that the roller maintains its performance and integrity even in challenging operating conditions, further enhancing its reliability and longevity.The use of the Polished Tungsten Carbide Roller has brought significant benefits to manufacturers across various industries. Its versatility and adaptability make it an essential tool in the production of a wide range of products, including metal sheets, textiles, plastics, and more. The roller's ability to withstand high temperatures and heavy loads makes it indispensable in demanding manufacturing processes, contributing to enhanced productivity and efficiency.Furthermore, the environmental benefits of the Polished Tungsten Carbide Roller cannot be overlooked. Its exceptional durability and wear resistance minimize the need for frequent replacements, resulting in reduced material waste and energy consumption. This aligns with [Company Name]'s commitment to sustainability and eco-friendly practices, further establishing the roller as a responsible choice for manufacturers.In conclusion, the Polished Tungsten Carbide Roller has proven to be a game-changer in the manufacturing industry, thanks to its exceptional performance, reliability, and environmental benefits. As a leading innovator in the field, [Company Name] continues to set new standards for quality and excellence, driving the industry forward with groundbreaking products like the Polished Tungsten Carbide Roller. With its unparalleled capabilities, the roller has undoubtedly become an indispensable asset for manufacturers seeking to elevate their production processes and maintain a competitive edge in today's dynamic market.

The Superior Performance of Tungsten Carbide Wire Rolls

Tungsten Carbide Wire Rolls are revolutionizing the wire manufacturing industry with their superior strength, durability, and precision. These rolls, manufactured by [Company Name], are setting a new standard for wire production, ensuring top-quality products for a wide range of applications.[Company Name] has been a leader in the production of tungsten carbide wire rolls for over two decades. The company prides itself on its commitment to innovation and quality, constantly seeking new ways to improve its products and stay ahead of the competition. With state-of-the-art manufacturing facilities and a team of dedicated engineers and technicians, [Company Name] has established itself as a trusted partner for wire manufacturers around the world.Tungsten carbide is a hard and dense material that is perfect for the demanding requirements of wire manufacturing. When used in wire rolls, it offers exceptional wear resistance and thermal conductivity, ensuring a longer service life and consistent performance. This makes tungsten carbide wire rolls ideal for a wide range of applications, including the production of steel wire, copper wire, and aluminum wire, among others.One of the key advantages of tungsten carbide wire rolls is their ability to maintain their shape and dimensions, even under high loads and temperatures. This ensures that the wire produced is of uniform quality, with precise dimensions and a smooth surface finish. As a result, manufacturers can rely on tungsten carbide wire rolls to achieve tight tolerances and high productivity, leading to cost savings and improved competitiveness.In addition to their exceptional performance, tungsten carbide wire rolls also offer environmental benefits. Their long service life means that they need to be replaced less frequently, reducing waste and the consumption of resources. Furthermore, their high precision and dimensional stability help minimize material waste during the wire manufacturing process, contributing to a more sustainable and efficient production.[Company Name] is committed to supporting its customers in maximizing the potential of tungsten carbide wire rolls. The company offers a range of services, including roll design and customization, technical support, and training programs. This ensures that customers can fully leverage the benefits of tungsten carbide wire rolls and optimize their wire manufacturing processes.With the growing demand for high-quality wire products across various industries, the need for reliable and high-performance wire rolls has never been greater. [Company Name] is well-positioned to meet this demand, with its extensive experience and expertise in the development and production of tungsten carbide wire rolls. The company's dedication to quality and customer satisfaction has earned it a strong reputation in the wire manufacturing industry, making it a preferred partner for wire producers worldwide.In conclusion, tungsten carbide wire rolls from [Company Name] are a game-changer for the wire manufacturing industry. Their exceptional performance, durability, and environmental benefits make them the ideal choice for wire producers looking to enhance their competitiveness and sustainability. With a focus on innovation and customer support, [Company Name] is poised to continue leading the way in the development of advanced wire roll solutions, driving the industry forward.