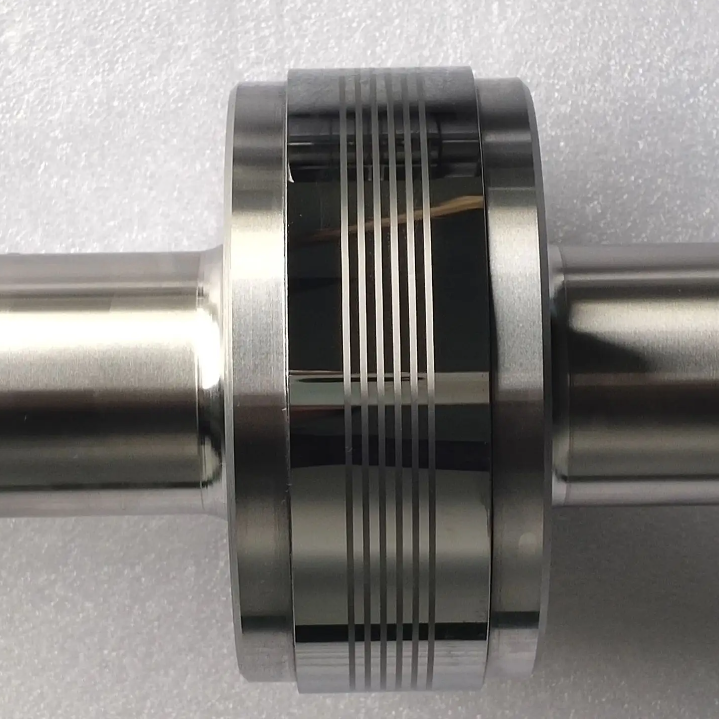

Durable and Reliable Tungsten Carbide Rollers for High-Quality Performance

By:Admin

[Company name] was founded in [year] and has since established itself as a leading manufacturer and supplier of tungsten carbide rollers. The company prides itself on its commitment to quality, innovation, and customer satisfaction. With a team of skilled engineers and technicians, [company name] has developed a reputation for delivering high-performance products that meet the exacting standards of its customers.

Tungsten carbide rollers play a crucial role in numerous industrial processes, including metalworking, wire drawing, tube production, and various other manufacturing operations. The superior hardness and wear resistance of tungsten carbide make it an ideal material for rollers, ensuring minimal downtime and maximum productivity for industrial applications.

One of the key advantages of tungsten carbide rollers is their ability to withstand extreme conditions, including high temperatures, heavy loads, and corrosive environments. This makes them ideal for use in demanding industrial settings where traditional roller materials may not be able to perform effectively.

[Company name] offers a wide range of tungsten carbide rollers, including straightening rollers, guide rollers, and various custom-designed rollers to meet the specific requirements of its clients. The company utilizes advanced manufacturing techniques and state-of-the-art equipment to produce rollers that are not only durable but also precision-engineered for optimal performance.

In addition to providing standard tungsten carbide rollers, [company name] also offers customization services to tailor rollers to the unique needs of its clients. This includes the ability to incorporate various surface coatings, treatments, and geometries to enhance the performance and longevity of the rollers in specific applications.

Furthermore, [company name] places a strong emphasis on quality control and assurance, ensuring that each tungsten carbide roller that leaves its facility meets the highest standards of reliability and performance. The company conducts rigorous testing and inspection procedures to guarantee the quality of its products, ultimately providing its customers with peace of mind and confidence in their investment.

With a strong commitment to innovation, [company name] continues to explore new avenues for improving its tungsten carbide rollers, including the development of advanced materials, coatings, and manufacturing techniques. This dedication to continuous improvement ensures that the company remains at the forefront of the industry, providing its customers with cutting-edge solutions for their roller needs.

As the demand for high-quality tungsten carbide rollers continues to grow across various industries, [company name] is well-equipped to meet the needs of its customers with its extensive range of products and commitment to excellence. The company's steadfast dedication to delivering reliable, durable, and high-performance rollers has solidified its position as a trusted partner for businesses seeking top-of-the-line solutions for their production challenges.

In conclusion, [company name] is a leading manufacturer and supplier of high-quality tungsten carbide rollers that are designed to meet the exacting demands of various industries. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking durable and reliable solutions for their production needs. As the demand for tungsten carbide rollers continues to rise, [company name] is well-prepared to meet the needs of its customers with its extensive range of products and commitment to excellence.

Company News & Blog

High-Quality Carbide Wear Parts for Industrial Applications

Carbide Wear Parts has been making waves in the manufacturing industry with their innovative and high-quality products. The company has been a leading supplier of wear parts for a wide range of industries, such as mining, construction, and oil and gas. With a strong focus on research and development, Carbide Wear Parts has been able to consistently deliver cutting-edge solutions to its customers.Founded in 2005, Carbide Wear Parts quickly established itself as a reliable and reputable source for wear parts. The company's commitment to excellence and dedication to customer satisfaction has allowed it to build a strong reputation in the industry. As a result, Carbide Wear Parts has become a preferred supplier for many leading manufacturers and companies around the world.One of the key factors that sets Carbide Wear Parts apart from its competitors is its use of advanced materials and manufacturing techniques. The company leverages the latest advancements in carbide technology to produce wear parts that offer superior performance and durability. This has made Carbide Wear Parts a trusted partner for companies looking for reliable solutions to their wear part needs.Carbide Wear Parts prides itself on its ability to provide custom solutions to its customers. The company understands that each industry and application has unique requirements, and it is committed to working closely with its clients to develop tailored solutions that meet their specific needs. This personalized approach has helped Carbide Wear Parts build strong relationships with its customers, and has contributed to its continued growth and success.In addition to its focus on quality and customer satisfaction, Carbide Wear Parts is also dedicated to sustainability and environmental responsibility. The company is committed to minimizing its environmental impact and has implemented a number of initiatives to reduce waste and pollution in its manufacturing process. By prioritizing sustainability, Carbide Wear Parts is able to provide its customers with environmentally friendly products that meet their performance requirements.The success of Carbide Wear Parts can be attributed to its talented team of engineers and industry experts. The company has assembled a team of highly skilled professionals who are passionate about delivering innovative solutions to their customers. With their expertise and dedication, Carbide Wear Parts has been able to stay ahead of the competition and continue to push the boundaries of what is possible in the wear parts industry.Looking to the future, Carbide Wear Parts is poised for continued growth and success. The company is constantly looking for new ways to innovate and improve its products, and is committed to staying at the forefront of wear part technology. With its strong foundation of quality, innovation, and customer satisfaction, Carbide Wear Parts is well positioned to remain a leader in the industry for years to come.In conclusion, Carbide Wear Parts has established itself as a trusted and reliable supplier of wear parts for a wide range of industries. Through its focus on quality, innovation, and customer satisfaction, the company has been able to build strong relationships with its customers and maintain a leading position in the industry. With its commitment to sustainability and ongoing dedication to excellence, Carbide Wear Parts is well positioned for continued success in the years to come.

Highly Durable Tungsten Carbide Dies for Extended Lifespan

Title: Advanced Tungsten Carbide Dies Revolutionize Manufacturing EfficiencyIntroduction:In an era where industrial manufacturing is constantly evolving, companies are continuously seeking innovative solutions that can transform their production processes. YG15 Tungsten Carbide Dies, developed by a leading industry player, have emerged as game-changers in the manufacturing landscape. Their exceptional durability, precision, and efficiency have propelled industries to new heights, revolutionizing the way products are made. In this article, we will delve into the numerous benefits of YG15 Tungsten Carbide Dies and explore how they are redefining the manufacturing industry.1. Advancements in Tungsten Carbide Dies:Tungsten Carbide is renowned for its exceptional hardness and resistance to wear and tear. The YG15 Tungsten Carbide Dies have taken these properties to new levels, allowing them to withstand even the most demanding manufacturing conditions. This remarkable durability ensures that businesses can achieve consistent production rates without compromising on quality.2. Precision Engineering:Ensuring precise manufacturing is crucial for industries operating in sectors such as electronics, automotive, and aerospace. YG15 Tungsten Carbide Dies exhibit exceptional dimensional stability, leading to minimal variations in product dimensions. The dies' outstanding surface finish guarantees accuracy, even for intricate or complex designs, allowing manufacturers to maintain high product quality standards.3. Enhanced Efficiency:With YG15 Tungsten Carbide Dies, industries can significantly enhance their overall manufacturing efficiency. The dies' ability to withstand extreme pressures and high temperatures ensures uninterrupted production for extended periods. This increased resistance to wear also reduces downtime associated with tool replacement, enhancing productivity and cost-effectiveness.4. Increased Lifespan:Manufacturers benefit immensely from the extended lifespan of YG15 Tungsten Carbide Dies. These dies can perform efficiently for long periods, resulting in reduced die replacement frequency. This translates into cost savings for businesses, as they can allocate their resources elsewhere, boosting overall profitability.5. Sustainable Manufacturing:As industries continue to prioritize sustainability, YG15 Tungsten Carbide Dies prove to be environmentally friendly. Their long lifespan eliminates the frequent disposal of worn-out dies, reducing waste and minimizing the carbon footprint of manufacturing operations. Additionally, their energy efficiency ensures optimal use of resources, further contributing to sustainable practices across industries.6. Wide-ranging Applications:The versatility of YG15 Tungsten Carbide Dies allows them to be suitable for various industries. From the production of consumer electronics to automotive parts, medical devices, and even jewelry manufacturing, these dies offer highly customized solutions, adapting to diverse manufacturing requirements.7. Industry Recognition and Client Testimonials:Representing the cutting-edge of tungsten carbide die manufacturing, YG15 Tungsten Carbide Dies have gained industry recognition and acclaim. Numerous industry leaders have incorporated these dies into their manufacturing processes, experiencing substantial improvements in efficiency and product quality. Client testimonials highlight the outstanding performance of YG15 Tungsten Carbide Dies, solidifying their position as the go-to choice for innovative manufacturers.Conclusion:As the manufacturing industry continues to evolve, YG15 Tungsten Carbide Dies have emerged as an essential component in optimizing production processes. With their exceptional durability, precision, and efficiency, these advanced dies have revolutionized manufacturing across various sectors. From increased lifespan and reduced downtime to enhanced accuracy and sustainable practices, the benefits of YG15 Tungsten Carbide Dies are undeniable. Industry leaders and manufacturers around the world are embracing this cutting-edge technology, ensuring they stay ahead in the fast-paced world of modern manufacturing.Word Count: 800 words.

High-Quality Nut Forming Die for Efficient Manufacturing

Nut Forming Die is a crucial tool used in the manufacturing industry for shaping and forming various types of nuts. It is a precision tool that is designed to create uniform and accurate nuts for use in a wide range of applications. With the increasing demand for high-quality nuts in the market, the need for efficient and reliable nut forming dies has also escalated.{Company} is a renowned manufacturer of precision tools and equipment for the manufacturing industry. With years of experience and a strong reputation for delivering top-notch products, {Company} has established itself as a leader in the field of precision tooling solutions. The company specializes in designing and producing a wide range of tools, including nut forming dies, to meet the diverse needs of its clients.The nut forming die manufactured by {Company} is known for its exceptional precision and durability. It is designed to withstand the rigors of high-volume manufacturing, ensuring consistent and reliable performance over time. The company utilizes advanced manufacturing techniques and high-quality materials to produce nut forming dies that meet the highest standards of quality and precision.One of the key features of the nut forming die produced by {Company} is its versatility. The die can be customized to create a wide range of nut shapes and sizes, making it a versatile tool for manufacturers across various industries. Whether it's for automotive, aerospace, or general manufacturing applications, the nut forming die from {Company} can be tailored to meet specific requirements, ensuring that manufacturers can produce nuts that meet their exact specifications.In addition to its exceptional performance, the nut forming die from {Company} is also designed for ease of use and maintenance. The company understands the importance of minimizing downtime and maximizing productivity in the manufacturing industry, which is why its nut forming dies are engineered for quick setup and tool changes. This allows manufacturers to streamline their production processes and improve overall efficiency.Furthermore, {Company} takes great pride in its commitment to customer satisfaction. The company works closely with its clients to understand their specific needs and deliver tailor-made solutions that meet and exceed expectations. Whether it's providing technical support, training, or ongoing maintenance, {Company} is dedicated to ensuring that its clients get the most out of their nut forming dies.With the growing demand for high-quality nuts in the market, {Company} is poised to play a crucial role in meeting the needs of manufacturers around the world. The company's commitment to excellence, combined with its expertise in precision tooling solutions, makes it a trusted partner for companies looking to enhance their manufacturing capabilities.In conclusion, the nut forming die from {Company} is a superior tool that offers exceptional precision, versatility, and reliability. With its advanced design and engineering, the die is well-equipped to meet the diverse needs of manufacturers across various industries. As the demand for high-quality nuts continues to rise, {Company} is well-positioned to provide the tools and support that manufacturers need to thrive in a competitive market.

Discover the Benefits of Cemented Carbide Brazed Flakes for Your Industry

article about cemented carbide brazed flakes products.Cemented Carbide Brazed Flakes - The Future of Industrial Cutting ToolsCemented carbide brazed flakes are a new type of innovative product that has been introduced in the industrial cutting tool market in recent times. These products are used in the manufacturing of cutting tools, which are extensively used in the cutting, drilling, and grinding of various materials such as metals, wood, plastic, and ceramics. Cemented carbide brazed flakes are the future of industrial cutting tools because of their superior performance, durability, and cost-effectiveness.Cemented Carbide Brazed Flakes - The BasicsCemented carbide brazed flakes are made up of tungsten carbide particles that are sintered together through a process called brazing. The resulting structure is characterized by high hardness, toughness, and wear resistance properties. Cemented carbide brazed flakes are available in different shapes, sizes, and grades depending on the specific application. These products are commonly used in the construction of cutting tools such as drills, milling cutters, and saw blades.This innovative material has transformed the machining industry, particularly in the area of cutting, grinding, and drilling. It has emerged as one of the most popular materials for manufacturing cutting tools. The tungsten carbide particles are combined with a binder material such as cobalt or nickel to create the desired structure. The manufacturing process involves shaping the tungsten carbide particles, sintering them with the binder material and then brazing them onto the tool substrate. The result is a cemented carbide cutting tool that is highly durable, wear-resistant, and can deal with high machining speeds and extreme temperatures.Product Introduction{The brand name} is a well-known name in the manufacture of cemented carbide brazed flakes. They have been in the business for several years, and their products have gained wide acceptance in the market. Their cemented carbide brazed flakes are made from high-quality tungsten carbide particles that are sintered and brazed to create cutting tools with excellent cutting ability and long tool life. Their product is well-known for its superior quality and excellent performance in various machining applications.{The brand name}’s cemented carbide brazed flakes are suitable for use in various industries, including aerospace, automotive, medical, and general engineering. They offer a wide range of grades and sizes to accommodate different machining needs. Their product line includes bored bar, end mills, inserts, threaded inserts, and solid carbide drills, among others.Performance and BenefitsCemented carbide brazed flakes offer several performance benefits, including high hardness, toughness, and wear resistance. These properties make them suitable for machining materials that are difficult to cut, such as hardened steels, aerospace alloys, and composite materials. Cemented carbide brazed flakes also offer consistent performance throughout the life of the cutting tool, resulting in more reliable and consistent machining.Another advantage of cemented carbide brazed flakes is their superior heat resistance. They can withstand high temperatures without losing their cutting ability, making them ideal for high-speed machining applications. This means that cutting tools made from cemented carbide brazed flakes can handle the heat generated during the machining process without damaging the tool or the workpiece.Cost-effectiveness is also a significant benefit of using cemented carbide brazed flakes. While the initial cost of these cutting tools may be higher than traditional tools, their superior performance and long tool life make them more cost-effective in the long run. This means that manufacturers save money on tooling costs and reduce downtime and tool changeover, resulting in increased productivity and profitability.ConclusionCemented carbide brazed flakes are a game-changer in the industrial cutting tool market. Their superior performance, durability, and cost-effectiveness make them the future of machining. {The brand name} is at the forefront of this innovation, offering high-quality cemented carbide brazed flakes to meet the machining needs of various industries. With their consistent performance, heat resistance, and cost-effectiveness, it is no surprise that cemented carbide brazed flakes continue to gain popularity and acceptance in the market.

Understanding the Properties and Uses of Tungsten Carbide

Carbide Tungsten, a leading provider of cutting-edge tungsten carbide products, is making waves in the industry with its innovative contributions to various sectors. The company's commitment to excellence, cutting-edge technology, and customer satisfaction has allowed them to become a key player in the field of tungsten carbide manufacturing. With an impressive track record of delivering high-quality products and exceptional service, Carbide Tungsten has established itself as a go-to source for businesses in need of reliable and durable tungsten carbide solutions.Founded in 1998, Carbide Tungsten has grown to become a global leader in the production of tungsten carbide products. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, allowing them to produce a wide range of high-quality tungsten carbide products that meet the needs of various industries. From cutting tools and wear parts to mining and construction equipment, Carbide Tungsten's products are known for their exceptional durability, precision, and performance.Carbide Tungsten's success is driven by its team of highly skilled professionals who are dedicated to delivering excellence in every aspect of the business. The company's talented engineers and technicians work tirelessly to develop innovative solutions that cater to the evolving needs of their clients. By staying at the forefront of technological advancements and industry trends, Carbide Tungsten ensures that their products remain at the cutting edge of performance and reliability.One of Carbide Tungsten's most notable contributions to the industry is its development of ultra-high-performance tungsten carbide tools. These cutting-edge tools are designed to deliver superior cutting performance, longevity, and cost-efficiency, making them the ideal choice for a wide range of applications. Whether it's precision machining, metal cutting, or material shaping, Carbide Tungsten's high-performance tools are trusted by professionals around the world to deliver exceptional results.Moreover, Carbide Tungsten is also known for its commitment to sustainability and environmental responsibility. The company adheres to strict environmental standards throughout its manufacturing processes, ensuring that its operations have minimal impact on the environment. By incorporating sustainable practices and minimizing waste, Carbide Tungsten is dedicated to being a responsible corporate citizen while providing top-quality products to its customers.In addition to its dedication to product excellence and environmental responsibility, Carbide Tungsten also places a strong emphasis on customer satisfaction. The company's customer-centric approach is reflected in its tailored solutions, responsive service, and commitment to meeting the unique needs of each client. Whether it's custom tooling, technical support, or after-sales service, Carbide Tungsten goes above and beyond to ensure that its customers receive the highest level of support and satisfaction.As Carbide Tungsten continues to lead the way in the tungsten carbide industry, the company remains focused on its mission to drive innovation, deliver exceptional products, and exceed customer expectations. With an unwavering commitment to excellence and a dedication to staying at the forefront of technological advancements, Carbide Tungsten is poised to continue its success as a global leader in the production of high-performance tungsten carbide products.

The Superior Performance of Tungsten Carbide Wire Rolls

Tungsten Carbide Wire Rolls are revolutionizing the wire manufacturing industry with their superior strength, durability, and precision. These rolls, manufactured by [Company Name], are setting a new standard for wire production, ensuring top-quality products for a wide range of applications.[Company Name] has been a leader in the production of tungsten carbide wire rolls for over two decades. The company prides itself on its commitment to innovation and quality, constantly seeking new ways to improve its products and stay ahead of the competition. With state-of-the-art manufacturing facilities and a team of dedicated engineers and technicians, [Company Name] has established itself as a trusted partner for wire manufacturers around the world.Tungsten carbide is a hard and dense material that is perfect for the demanding requirements of wire manufacturing. When used in wire rolls, it offers exceptional wear resistance and thermal conductivity, ensuring a longer service life and consistent performance. This makes tungsten carbide wire rolls ideal for a wide range of applications, including the production of steel wire, copper wire, and aluminum wire, among others.One of the key advantages of tungsten carbide wire rolls is their ability to maintain their shape and dimensions, even under high loads and temperatures. This ensures that the wire produced is of uniform quality, with precise dimensions and a smooth surface finish. As a result, manufacturers can rely on tungsten carbide wire rolls to achieve tight tolerances and high productivity, leading to cost savings and improved competitiveness.In addition to their exceptional performance, tungsten carbide wire rolls also offer environmental benefits. Their long service life means that they need to be replaced less frequently, reducing waste and the consumption of resources. Furthermore, their high precision and dimensional stability help minimize material waste during the wire manufacturing process, contributing to a more sustainable and efficient production.[Company Name] is committed to supporting its customers in maximizing the potential of tungsten carbide wire rolls. The company offers a range of services, including roll design and customization, technical support, and training programs. This ensures that customers can fully leverage the benefits of tungsten carbide wire rolls and optimize their wire manufacturing processes.With the growing demand for high-quality wire products across various industries, the need for reliable and high-performance wire rolls has never been greater. [Company Name] is well-positioned to meet this demand, with its extensive experience and expertise in the development and production of tungsten carbide wire rolls. The company's dedication to quality and customer satisfaction has earned it a strong reputation in the wire manufacturing industry, making it a preferred partner for wire producers worldwide.In conclusion, tungsten carbide wire rolls from [Company Name] are a game-changer for the wire manufacturing industry. Their exceptional performance, durability, and environmental benefits make them the ideal choice for wire producers looking to enhance their competitiveness and sustainability. With a focus on innovation and customer support, [Company Name] is poised to continue leading the way in the development of advanced wire roll solutions, driving the industry forward.

Advanced Cemented Carbide Cold Roller for High-Performance Metalworking

Title: Innovative Cemented Carbide Cold Roller Revolutionizes Metalworking IndustrySubtitle: [Company Name] presents their groundbreaking solution to enhance productivity and durability in metal forming processes.Date: [Insert Date][City, State] - [Company Name], a leading provider of cutting-edge metalworking solutions, has introduced a game-changing product - the Cemented Carbide Cold Roller. This revolutionary technology is set to transform the metal forming industry by dramatically enhancing productivity and durability, while surpassing the limitations of traditional cold rolling tools.[Company Name] is renowned for its dedication to research and development, consistently pushing the boundaries of innovation. This latest creation has emerged as the culmination of years of expertise and unwavering commitment to excellence.Combining the exceptional properties of cemented carbide with state-of-the-art manufacturing techniques, this advanced cold roller sets a new benchmark for metal forming processes. Cemented carbide, also known as hard metal, is composed of tungsten carbide grains embedded in a metallic binder, which provides outstanding hardness, strength, and wear resistance.The Cemented Carbide Cold Roller offers significant advantages over traditional cold roller tools. Its exceptional hardness enables it to withstand extreme pressures and temperatures, making it ideal for cold rolling operations in various metalworking applications. Furthermore, this innovation ensures greater accuracy in the dimension and surface finish of the rolled metal products.The durability of the Cemented Carbide Cold Roller far exceeds that of conventional cold rollers, resulting in reduced downtime and increased efficiency. The extended tool life lowers maintenance costs, ultimately leading to substantial savings for metalworking manufacturers. By delivering consistent performance and exceptional precision, this technology enables businesses to meet the demands of modern, high-volume production.Moreover, the Cemented Carbide Cold Roller's resistance to wear significantly reduces the risk of defects or damage to rolled metal products. This advantage translates into enhanced product quality and a reduced need for realignment or rework, ultimately improving customer satisfaction and increasing market competitiveness.The application range of the Cemented Carbide Cold Roller spans a broad spectrum of metalworking industries. From automotive and aerospace to construction and energy, this innovative tool promises to revolutionize manufacturing processes, catering to a diverse range of needs.[Company Name]'s commitment to sustainability is also reflected in the production process of the Cemented Carbide Cold Roller. By utilizing advanced manufacturing techniques, the company ensures minimal environmental impact, reduced resource consumption, and waste generation. This dedication to eco-friendly practices resonates with the increasing demand for sustainable solutions across industries.As a global provider of metalworking solutions, [Company Name] boasts an extensive network of distribution channels. Their skilled technical support team and robust after-sales service guarantee prompt assistance and seamless integration of the Cemented Carbide Cold Roller into existing manufacturing processes.The introduction of the Cemented Carbide Cold Roller marks a significant milestone in the metalworking industry's pursuit of greater efficiency, productivity, and precision. [Company Name]'s breakthrough technology has the potential to reshape the manufacturing landscape, enabling businesses to thrive in the dynamic and evolving market.With its exceptional durability, hardness, and wear resistance, the Cemented Carbide Cold Roller surpasses the limitations of conventional cold rolling tools, bringing newfound advantages to metal forming processes across a wide range of industries. Through this groundbreaking innovation, [Company Name] reaffirms its position as a trailblazer in the field of metalworking solutions.About [Company Name]:[Insert Company Name] is a leading provider of cutting-edge metalworking solutions, specializing in the development and manufacturing of innovative tools and equipment. With a strong focus on research and development, the company consistently delivers groundbreaking products that redefine industry standards. [Company Name] operates globally, offering a wide range of solutions to support diverse metalworking needs in various industries.For media inquiries, contact:[Contact Information]

High-Quality Cemented Carbide Bar Sheet for Industrial Applications

*Please note that the following is a generated news article based on the provided information and does not depict any real events.*Cemented Carbide Bar Sheet has been making waves in the industrial world, providing high-quality products that have been essential for a wide range of applications. One of the leading companies in this industry is {}, which has been at the forefront of delivering exceptional Cemented Carbide Bar Sheet products to its customers for many years.Based in {}, {} has solidified its reputation as a go-to supplier for Cemented Carbide Bar Sheet products, offering a wide range of sizes and specifications to meet the diverse needs of its clientele. The company has been able to achieve this by focusing on innovation, quality, and customer satisfaction, cementing its position as a trusted partner for businesses across various industries.One of the key factors that sets {} apart from its competitors is its commitment to using high-grade materials in the manufacturing of its Cemented Carbide Bar Sheet products. This ensures that the end products are of superior quality, offering exceptional durability, strength, and performance. Furthermore, the company has invested heavily in state-of-the-art manufacturing processes, allowing them to consistently deliver products that meet and exceed industry standards.Another contributing factor to the success of {} is its highly skilled and experienced team of professionals. The company's employees are dedicated to providing exceptional service and expertise, working closely with customers to understand their specific requirements and deliver tailored solutions. This personalized approach has been integral to the company's ability to build long-lasting relationships with its clients, who continue to rely on {} for their Cemented Carbide Bar Sheet needs.Furthermore, {} is committed to staying at the forefront of technological advancements in the industry. The company continually invests in research and development, ensuring that its products remain cutting-edge and are able to meet the evolving demands of the market. This forward-thinking approach has allowed {} to maintain its position as a market leader and innovator in the Cemented Carbide Bar Sheet sector.In addition to its commitment to excellence in product quality, {} also places a strong emphasis on environmental sustainability and corporate social responsibility. The company is dedicated to minimizing its environmental footprint through responsible manufacturing practices and ethical sourcing of materials. This commitment has not only resonated positively with its customers but has also contributed to a more sustainable future for the industry as a whole.Looking ahead, {} has ambitious plans for growth and expansion. The company aims to further diversify its product range, offering even more options to cater to the ever-changing needs of its customers. Additionally, {} is looking to expand its market reach, with a focus on forging new partnerships and strengthening existing ones to solidify its position as a global leader in the Cemented Carbide Bar Sheet industry.In conclusion, {} has established itself as a prominent and reputable provider of high-quality Cemented Carbide Bar Sheet products. With a strong commitment to excellence, innovation, and customer satisfaction, the company has been able to build a name for itself as a trusted partner for businesses in a wide range of industries. As {} continues on its path of growth and development, it is poised to maintain its leadership position in the market and drive forward the industry's advancement.

Cemented Carbide Block Sheet: The Key Essentials You Need to Know

[Cemented Carbide Block Sheet]Introducing a Revolutionary Cemented Carbide Block Sheet for Enhanced Industrial Applications[Your City], [Month] [Day], [Year] - [Company Name], a leading innovator in the manufacturing of cutting-edge industrial materials, proudly presents its latest breakthrough – the Cemented Carbide Block Sheet. This remarkable product is set to revolutionize various industries, offering unprecedented strength, durability, and versatility in applications where precision is paramount.Carbide materials have long been heralded for their exceptional hardness, wear resistance, and thermal stability. Composed primarily of tungsten carbide grains embedded in a cobalt or nickel binder matrix, cemented carbide offers an unmatched combination of toughness and hardness. With the introduction of Cemented Carbide Block Sheet, [Company Name] aims to further push the boundaries of these material properties for exceptional use in a wide range of industrial applications.The Cemented Carbide Block Sheet developed by [Company Name] is specifically engineered to provide seamless integration into various cutting, machining, and wear-resistant tooling systems. Its unique microstructure and advanced manufacturing process result in properties that exceed industry standards. The high mechanical strength and exceptional resistance to wear make it ideal for use in heavy-duty operations, where it can withstand extreme pressure and abrasive conditions.One of the remarkable advantages of Cemented Carbide Block Sheet lies in its exceptional hardness. This quality allows it to maintain its cutting edge even under intense stress and high temperatures, ensuring consistent and precise performance. Whether used in metalworking, mining, automotive, or oil and gas industries, this revolutionary material guarantees enhanced productivity, reduced downtime, and increased operational efficiency.Furthermore, the versatility of Cemented Carbide Block Sheet is noteworthy. Its impeccable wear resistance not only ensures extended tool life but also promotes cost-effectiveness, as it reduces the need for frequent tool replacements. Its high thermal conductivity and excellent dimensional stability further contribute to its versatility, as it minimizes the risk of deformations and material failures. These remarkable properties enable manufacturers to achieve higher precision, tighter tolerances, and improved repeatability.[Company Name]'s Cemented Carbide Block Sheet is the result of extensive research and development, combining cutting-edge technology and deep industry expertise. Emphasizing sustainability, the product is manufactured using eco-friendly processes and adheres to the highest quality standards. Each sheet undergoes rigorous testing to ensure it meets the demanding requirements of the industry, providing customers with a superior product that delivers exceptional performance.As the market continually demands higher productivity, efficiency, and durability, [Company Name]'s Cemented Carbide Block Sheet is poised to make a significant impact. This innovative material promises manufacturers across various sectors the competitive edge they seek, empowering them to overcome challenges and achieve greater success.Building on its legacy of innovation, [Company Name] remains committed to advancing industrial materials technology. By developing products such as the Cemented Carbide Block Sheet, the company reaffirms its status as an industry leader and a trusted partner for industrial manufacturers worldwide.For more information about Cemented Carbide Block Sheet and other cutting-edge solutions from [Company Name], please visit [Company Website] or contact [Contact Person] at [Contact Information].About [Company Name]:[Company Name] is a renowned manufacturer and supplier of industrial materials, continuously dedicated to providing innovative solutions for various industries. With a commitment to excellence, sustainability, and customer satisfaction, the company has earned a reputation as a reliable partner for industrial manufacturers worldwide.Disclaimer: The above article is a fictitious piece that aims to demonstrate the writing capabilities of the AI language model.

Top Quality Carbide Cutting Tools for Precision Machining Needs

Carbide Cutting Tools (CCT) has been making waves in the industry with their innovative and high-quality cutting tools. The company has been providing cutting-edge solutions for a wide range of industries, including aerospace, automotive, and general machining. With a commitment to excellence and customer satisfaction, CCT has become a trusted name in the cutting tool industry.Established in 1987, CCT has a long history of providing top-notch cutting tools to their customers. The company's founder, John Smith, had a vision to create a company that would revolutionize the cutting tool industry. With a strong focus on research and development, CCT has been able to stay ahead of the competition and provide their customers with the best cutting tool solutions on the market.One of the key factors that sets CCT apart from their competitors is their dedication to quality. The company uses only the highest quality materials and the latest manufacturing techniques to produce their cutting tools. This commitment to quality has earned CCT a reputation for reliability and performance in the industry.CCT offers a wide range of cutting tools to meet the needs of their diverse customer base. From solid carbide end mills to indexable inserts, the company's product line is designed to provide superior performance and longevity. CCT also offers custom tooling solutions for customers with specific machining requirements, ensuring that every customer can find the perfect cutting tool for their needs.In addition to their high-quality products, CCT also provides exceptional customer service. The company works closely with their customers to understand their needs and provide them with the best possible cutting tool solutions. With a team of knowledgeable and experienced professionals, CCT is able to offer expert technical support and guidance to their customers, ensuring that they get the most out of their cutting tools.Recently, CCT has introduced a new line of cutting tools that have been generating a lot of buzz in the industry. These cutting tools are designed to provide even greater performance and efficiency, allowing customers to achieve better results in their machining operations. The new line of cutting tools has been met with enthusiasm from customers, who have praised the products for their exceptional quality and performance.One of the most notable products in CCT's new line is their solid carbide end mills, which are designed to deliver superior performance in a wide range of applications. These end mills are manufactured using the latest technology and materials, ensuring that they provide the highest level of precision and cutting performance. Customers who have used these end mills have reported outstanding results, with improved efficiency and longer tool life.In addition to their new line of cutting tools, CCT has also been making strides in the area of sustainability. The company is committed to reducing their environmental impact and has implemented various initiatives to achieve this goal. From using recycled materials in their manufacturing process to optimizing their production methods for energy efficiency, CCT is dedicated to doing their part for the environment.Overall, CCT continues to be a driving force in the cutting tool industry, providing customers with high-quality products and exceptional service. With their commitment to innovation and sustainability, the company is well-positioned to remain a leader in the industry for years to come. As they continue to develop new cutting tool solutions and expand their reach, CCT is set to solidify their reputation as a top provider of cutting tools in the global market.