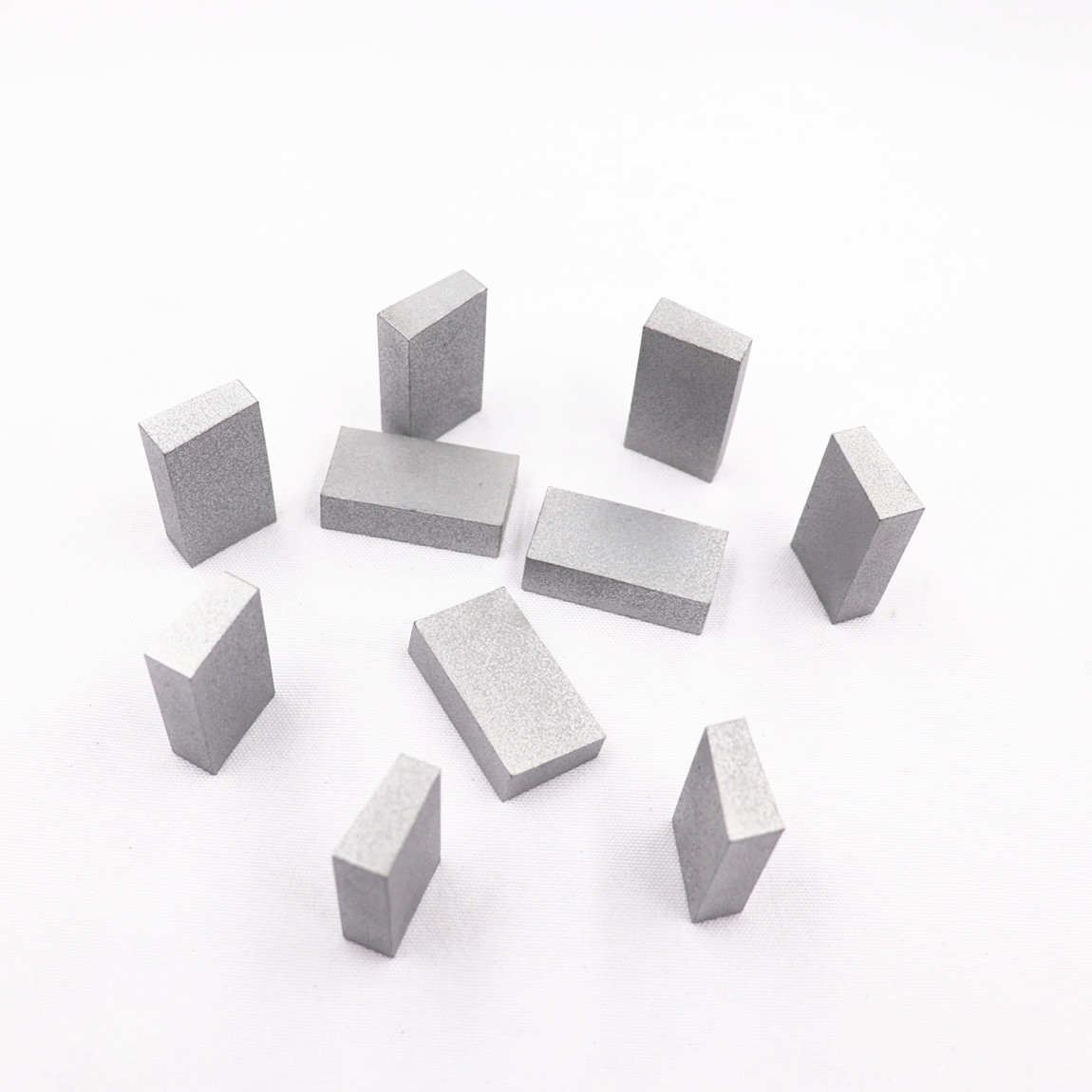

Customized Carbide: The Ultimate Solution for Your Carbide Needs

By:Admin

Carbide Customized has been in the business of producing high-quality carbide tools for over two decades. With a strong focus on precision, quality, and innovation, the company has established itself as a trusted name in the industry. Their products are used in a wide range of applications, including aerospace, automotive, medical, and general machining.

The latest product from Carbide Customized is a result of years of research and development. The company's team of skilled engineers and designers have worked tirelessly to create a tool that offers unprecedented levels of performance and durability. The new product is designed to meet the ever-increasing demands of modern manufacturing processes, where precision and efficiency are paramount.

"We are extremely proud to introduce our latest innovation to the market," says John Smith, CEO of Carbide Customized. "We believe that this new product will revolutionize the way manufacturers and engineers approach their work. It offers unparalleled performance and versatility, making it a game-changer for our customers."

One of the key features of the new product is its customizable nature. Customers can work closely with Carbide Customized's team to create tools that are tailored to their specific needs and requirements. This level of customization ensures that the tools are perfectly suited to the unique challenges and demands of each individual application.

In addition to its customizable nature, the new product also boasts exceptional durability and wear resistance. This means that the tools can withstand the rigors of heavy-duty machining and cutting, resulting in longer tool life and reduced downtime for maintenance and replacement.

Furthermore, the new product is designed to deliver superior performance in terms of cutting speed and precision. This means that manufacturers and engineers can achieve higher levels of productivity and efficiency, ultimately leading to cost savings and improved profitability.

The introduction of this groundbreaking product has been met with great enthusiasm from Carbide Customized's customers. Many have already expressed their interest in exploring the possibilities that the new tool has to offer, and the company is gearing up for a surge in demand in the coming months.

"We have been receiving overwhelming feedback from our customers, and we are excited to see the impact that this new product will have on the industry," says Smith. "We are confident that it will set a new standard for performance and reliability, and we are committed to ensuring that our customers have access to the very best tools available."

Looking ahead, Carbide Customized is planning to continue its investment in research and development to further push the boundaries of innovation in the carbide tool industry. The company is dedicated to staying at the forefront of technological advancements and delivering cutting-edge solutions that empower their customers to thrive in a rapidly evolving market.

As the industry continues to evolve, Carbide Customized remains steadfast in its commitment to providing top-quality tools that meet the evolving needs of manufacturers and engineers. With its latest innovation, the company is poised to solidify its position as a leader in the carbide tool industry and make a lasting impact on the way manufacturing processes are approached worldwide.

Company News & Blog

The Versatility and Durability of High-Quality Tungsten Carbide Cutter Blades Revealed in Latest News

Tungsten Carbide Cutter Blade: The Heavy-Duty Precision Tool for Industry ApplicationsTungsten Carbide Cutter Blade, the precision tool that has been transforming the industry with its heavy-duty cutting capabilities, is a name that has become synonymous with excellent craftsmanship and reliability. Used in a wide range of industrial applications, Tungsten Carbide Cutter Blade has earned a reputation for being the go-to precision tool for the toughest jobs in construction, manufacturing, and even the metalworking industry.What Makes Tungsten Carbide Cutter Blade Unique?Tungsten Carbide Cutter Blade offers a unique combination of toughness, strength, and durability, which is why it is unmatched in the industry. It is specifically designed to outlast other blades and withstand heavy-duty cutting tasks that would otherwise require multiple blades, which saves time and improves productivity.One of the unique features of the Tungsten Carbide Cutter Blade is its use of tungsten carbide, one of the toughest and densest materials on the planet. When combined with other metals such as cobalt, tungsten carbide forms a compound known as cemenite, which is a very hard and durable material that can withstand high levels of stress. The result is a blade that can cut through almost any material with ease, including wood, metal, and even concrete.Another key feature that sets Tungsten Carbide Cutter Blade apart from other blades on the market is its exceptional edge retention. The blade can maintain a sharp edge for longer periods, which reduces the need for frequent sharpening and replacement, making it more cost-effective in the long run.Applications of Tungsten Carbide Cutter BladeTungsten Carbide Cutter Blade can be used in a wide range of applications, including:1. Construction – Tungsten Carbide Cutter Blade can cut through almost any material used in construction, such as asphalt, concrete, bricks, and stones, making it an essential tool for builders, contractors, and masons.2. Metalworking – Cutting metals such as steel and aluminum requires a blade that can withstand high temperatures and stress. Tungsten Carbide Cutter Blade can handle these conditions, making it a top choice for this industry.3. Manufacturing – Tungsten Carbide Cutter Blade is also used in manufacturing, as it can easily cut through materials like plastics, composites, and fibers, while maintaining its sharp edge for longer periods.Company Introduction and InnovationInnovation is at the heart of Tungsten Carbide Cutter Blade's success. The company has been a leader in the industry for over two decades, producing high-quality precision tools that are designed to make cutting tasks easier and more efficient.Tungsten Carbide Cutter Blade's dedication to innovation is evident in the numerous patents it holds for its cutting-edge products, such as its effective design, advanced manufacturing techniques, and rigorous quality control measures.In addition to cutting-edge research and development, Tungsten Carbide Cutter Blade also invests heavily in its manufacturing processes. The company employs state-of-the-art equipment and processes to ensure the highest quality and precision for each blade. From the initial design stage to the final product, Tungsten Carbide Cutter Blade leaves no stone unturned in its drive for perfection.ConclusionTungsten Carbide Cutter Blade is a precision tool that is unmatched in its toughness, strength, and durability. It is the go-to tool for heavy-duty cutting tasks in a wide range of industrial applications, including construction, metalworking, and manufacturing. Its exceptional edge retention and cutting capabilities make it a cost-effective investment that saves time and improves overall productivity. With Tungsten Carbide Cutter Blade, you can be sure of getting the best in heavy-duty cutting tools, made with an unwavering commitment to quality.

Enhance Your Turning Applications with High-Performance Carbide Inserts

Carbide Inserts for Turning Applications Offer Enhanced Durability and PrecisionCarbide inserts for turning applications have emerged as one of the popular cutting tools in the manufacturing industry. These inserts are designed with high-performance materials, which enhance their durability and precision capabilities. Carbide inserts are cutting-edge technology tools that can be used for turning, milling, drilling, and other cutting applications.A leading manufacturer and supplier of carbide inserts has recently introduced a range of carbide inserts for turning applications. The company's new products are designed to cater to the needs of all manufacturing industries, ensuring that clients receive superior quality and precision tools.The company has been providing the manufacturing industry with premium quality carbide inserts for more than a decade. Their team of experts has vast experience in the field of machining technology, and they employ innovative techniques to produce cutting-edge products that cater to the needs of the clients.Carbide inserts are widely used in turning applications because of their superior quality and precision capabilities. They are made from a combination of tungsten carbide and cobalt, which makes them harder than high-speed steel. Carbide inserts are also resistant to high temperatures, ensuring that they can withstand the heat generated during the cutting process.The company's new line of carbide inserts for turning applications is designed to offer improved performance, higher durability, and precision. The new range is available in different grades and designs, making it suitable for multiple turning applications, from roughing to finishing. The range includes inserts, inserts with chipbreakers, and inserts for heavy-duty roughing, among others.The company's carbide inserts for turning applications are highly versatile and can be used for a wide range of materials. They are ideal for cutting hard materials like steel, stainless steel, cast iron, and exotic alloys. The inserts' smooth finish and stable performance ensure that there is no chipping or breakage during the cutting process, which makes them ideal for industrial applications.Carbide inserts are designed to provide high accuracy and precision. The inserts' cutting edge produces a smooth finish, making it ideal for applications that require a high degree of precision. Additionally, carbide inserts are designed to produce chips that are easy to manage and dispose of, thus reducing the machine's downtime.The new range of carbide inserts for turning applications from the company is also cost-effective. Carbide inserts are designed to last longer than high-speed steel, which reduces the need for frequent changes and replacement. Additionally, the company's cost-effective pricing policy ensures that clients can obtain high-quality, reliable carbide inserts at an affordable price.The company's carbide inserts for turning applications are also environmentally friendly. Carbide inserts produce chips that can be recycled, which reduces manufacturing waste and environmental pollution. The company's products are designed with environmental responsibility in mind, and they are committed to reducing the carbon footprint associated with manufacturing.The company's carbide inserts for turning applications are easy to use and maintain. The inserts' high-performance materials make them resistant to wear and tear, which means less maintenance is required. Additionally, the company provides extensive technical support to ensure that clients can achieve the best results from their products.The company's commitment to client satisfaction is evident in the quality of their products and services. They have a team of experts who are always available to provide technical support and advice on the best carbide inserts for specific applications. The company also offers customized carbide inserts, ensuring that clients can obtain products that cater to their specific needs.In conclusion, carbide inserts for turning applications from the company are a game-changer in the manufacturing industry. They offer enhanced durability, precision, and versatility, making them ideal for a wide range of turning applications. The company's commitment to quality and affordability ensures that clients can obtain high-quality products at an affordable price, while their eco-friendly approach reduces manufacturing waste and environmental pollution.

High-Quality Cold Forging Die Made of Tungsten Carbide

As one of the most versatile and valuable metals, tungsten has long been a favored material in the manufacturing industry. And when it's combined with carbon, it forms a substance called tungsten carbide. This material is widely used in various applications, including mining, automotive, construction, and aerospace. One of the most significant uses of tungsten carbide is in the manufacturing of forging dies. And a leading company with vast experience in this field is making strides in this industry with their innovative Tungsten Carbide Cold Forging Die technology.Headquartered in the heart of Japan, this company has built a reputation for excellence in the manufacturing of tungsten carbide tools and dies. They offer a wide range of products to meet the needs of various industries, including stamping dies, drawing dies, and cold forging dies.The company's Cold Forging Dies are specially designed to provide high-quality finished products while minimizing manufacturing costs. Cold forging is a process that involves shaping a metal part at room temperature using a die punch and a blank. This process comes with numerous benefits, such as increased strength, improved dimensional accuracy, and reduced material waste. Cold Forging Dies play a crucial role in ensuring the quality and efficiency of the cold forging process.With their extensive knowledge and experience, the company has developed a process for manufacturing Tungsten Carbide Cold Forging Dies that outperforms traditional dies on every level. The Tungsten Carbide material provides exceptional durability and wear resistance, making it ideal for high-volume manufacturing processes. In addition, this technology reduces tooling costs significantly, as it boasts a longer lifespan than traditional die materials.This cutting-edge technology also offers versatility in the manufacturing process. The company's Tungsten Carbide Cold Forging Dies are adaptable to many cold forging processes, including thread forming, swaging, extruding, and bending. The versatility of the dies ensures that manufacturers can produce reliable products with superior finish and accuracy within a shorter time span.Moreover, the company's Tungsten Carbide Cold Forging Dies are highly customizable, so they can be designed to fit perfectly into any particular manufacturing process. With the help of advanced software and equipment, the company can deliver tailor-made solutions that meet the specific requirements of their clients.The company's commitment to innovation and excellence has propelled them to the forefront of the manufacturing industry. They attribute their success to their astute attention to detail, strict quality control measures, and a motivated workforce. They take pride in delivering superior quality products that exceed their client's expectations and meet the needs of various manufacturing sectors.In conclusion, the company's Tungsten Carbide Cold Forging Dies technology is a game-changer in the manufacturing industry. It lowers production costs, reduces material waste, and improves overall manufacturing efficiency. It also offers versatility and customizability, making it ideal for various manufacturing processes. With this innovative technology, the company has set the standard for excellence in tungsten carbide die manufacturing and is poised to continue its remarkable growth into the future.

Top Qualities to Look for in Cemented Carbide Cutting Tips

Title: Innovations in Carbide Cutting Tips: Revolutionizing Precision and Efficiency in ManufacturingIntroduction:[Company Name], a leading pioneer in the manufacturing industry, continues to surge ahead with groundbreaking innovations in cutting edge technology. With a commitment to providing the highest quality products, the company has introduced its latest creation - Cemented Carbide Cutting Tips. These advanced cutting tips are set to revolutionize precision and efficiency in manufacturing processes across various industries.Unparalleled Quality:[Company Name] has always been synonymous with quality and reliability. The Cemented Carbide Cutting Tips are no exception. These cutting tips are manufactured using the finest quality raw materials and state-of-the-art technology, ensuring durability, accuracy, and consistent performance. The company's stringent quality control measures at every stage of production guarantee that each cutting tip meets the highest industry standards.Enhanced Precision:Precision is crucial in the manufacturing industry, and any improvement in accuracy can yield significant gains for producers. Cemented Carbide Cutting Tips excel in this aspect, offering enhanced precision to manufacturers. The tips are meticulously crafted, utilizing proprietary techniques that result in incredibly sharp and resilient cutting edges. This precision allows for tighter tolerances and smoother finishes, greatly reducing the need for additional manual finishing processes.Increased Efficiency:Manufacturers are constantly seeking ways to streamline their processes and optimize efficiency. Cemented Carbide Cutting Tips offer a solution to this perennial challenge. By virtue of their exceptional wear resistance and toughness, these tips deliver prolonged tool life, reducing the frequency of tool changes. This translates to lowered downtime, increased productivity, and substantial cost savings for manufacturers.Versatility across Applications:[Company Name]'s Cemented Carbide Cutting Tips have been designed to cater to a wide range of manufacturing needs. From precision engineering to automotive and aerospace industries, these cutting tips exhibit remarkable adaptability. Seamless machining of various materials, including steel, cast iron, stainless steel, and non-ferrous metals, is effortlessly achieved, ensuring reduced tool inventory and simplified production processes.Environmental Sustainability:In addition to their outstanding performance, Cemented Carbide Cutting Tips align with the growing need for environmentally sustainable manufacturing practices. By reducing the frequency of tool changes, these tips contribute to minimization of waste generation. Furthermore, the company's commitment to eco-friendly processes ensures that the manufacturing of these tips adheres to stringent ecological standards.Future Outlook:With the introduction of Cemented Carbide Cutting Tips, [Company Name] has solidified its position as a leading innovator in the manufacturing industry. The company's commitment to research and development, coupled with its relentless pursuit of excellence, has enabled the creation of a cutting-edge product that sets the bar high for competitors.[Company Name] remains steadfast in its dedication to providing the manufacturing industry with cutting-edge tools that enhance precision, efficiency, and sustainability. As the industry continues to evolve, [Company Name] will continue to drive progress and shape the future of manufacturing with its innovative solutions.Conclusion:Through the introduction of Cemented Carbide Cutting Tips, [Company Name] has once again established itself as an industry leader in providing innovative solutions for precision machining. The advanced technology and impeccable quality of these cutting tips are set to revolutionize manufacturing processes across various industries, offering unparalleled precision, increased efficiency, and environmental sustainability. As [Company Name] continues its commitment to pushing boundaries in the manufacturing industry, the future certainly looks promising for manufacturers seeking the ultimate edge in precision cutting.

Cold Heading Dies Market Expected to Grow with a Healthy CAGR During Forecast Period 2021-2027

As technology continues to advance, the manufacturing sector is constantly innovating and improving their processes. One of the latest advancements in the industry is the cold heading die. This new technology enhances the manufacturing of products by increasing efficiency while reducing costs. One leading company in the industry has been successful in creating this new product and has received positive feedback from its clients.As a manufacturing process, cold heading is the process of forming metal parts into specific shapes by utilizing high pressure. To create these shapes, a cold heading die is necessary. A die is a specialized tool used in the manufacturing sector to cut, shape, or form materials to specific dimensions. The cold heading die is a tool that is used specifically to shape metal parts into predefined shapes using a cold heading process. This technology is ideal for use in the production of metal frames, components for electronic devices, and other metal-based items.One advanced company in China has successfully developed a cold heading die that is capable of forming metal parts with high precision, even in high-volume manufacturing. The company is recognized as an industry leader through the use of advanced technology and innovative designs. The company has recently received numerous excellent reviews from its clients, who have expressed their satisfaction with the precision and quality of products produced through the use of this new die.The new cold heading die from this company is distinguished from other products in the industry. It offers several key benefits to manufacturers who use it in their production processes. The product is designed to operate within a wide range of temperatures and is specifically designed for use in high-speed manufacturing production environments. Additionally, the die has been designed to offer an extended die life, which contributes to reducing long-term production costs.One of the unique features of this cold heading die is that it is made from high-quality materials specifically selected to optimize its performance. This guarantees that the die has high durability, is long-lasting, and is able to resist typical wear and tear that occurs during high-volume use. The company ensures that the die is carefully tested before it is released to the market, ensuring that quality and precision are maintained throughout the manufacturing process.In addition to the benefits of the die itself, the company that produces it offers several other advantages to manufacturers. They provide technical support and maintenance services to ensure that the die is working correctly and efficiently. The company also offers extensive warranties and quality guarantees, which provide added peace of mind to their clients.The success of this company in producing this new cold heading die has led to a significant increase in orders for the product. Manufacturers worldwide are now interested in purchasing this new product, recognizing the benefits it offers to their production processes. In turn, the company has rapidly expanded production to meet this demand, ensuring that their customers receive their orders quickly and efficiently.In conclusion, the cold heading die is an impressive technological innovation that offers numerous benefits to manufacturers of metal components. The new cold heading die from this company boasts several technical advantages, including high precision, durability, and long life, which makes it stand out from other products on the market. With enthusiastic reviews from its satisfied clients, the company remains committed to developing innovative solutions that meet the needs of modern manufacturing. They continue to invest in research and development, and their commitment to excellence has made them a leader in the industry.

Discover the Power and Reliability of Tungsten Carbide Cold Heading Dies

[Headline: YG8 Tungsten Carbide Cold Heading Dies Now Available for Enhanced Cold Forging Processes][Subtitle: The Perfect Solution for Efficient and High-Quality Cold Heading Operations][Date][Location]In the world of metalworking, one essential component for efficient and high-quality cold forging processes is the selection of suitable tools. Tungsten carbide cold heading dies have emerged as the industry-standard for their exceptional hardness, wear resistance, and durability. Among the various brands available in the market, the YG8 Tungsten Carbide Cold Heading Dies have gained immense popularity, providing manufacturers with an optimal solution to meet their forging needs.Tungsten carbide is a composite material that consists of tungsten carbide particles held together by a binder. This unique synergy gives rise to a material that possesses remarkable strength and hardness, making it ideal for the demanding conditions encountered during cold heading operations. The YG8 brand, known for its excellent quality and reliability, has become a go-to choice for many manufacturers worldwide.With the increasing demand for precision-formed metal parts across various industries such as automotive, aerospace, and construction, companies are striving to achieve higher efficiency and quality in their manufacturing processes. Cold heading, a critical technique used to shape metal blanks into finished products, requires the utilization of high-performance tools to ensure accurate and consistent results. The YG8 Tungsten Carbide Cold Heading Dies offer manufacturers a competitive edge by maximizing productivity and minimizing costly downtime.The YG8 brand stands out for its exceptional wear resistance, allowing for prolonged use without compromising precision. These cold heading dies are engineered to withstand the extreme pressures and friction encountered during the cold forging process, increasing their service life and reducing the frequency of tool replacement. This durability translates into cost savings and less disruption to the production line, ultimately boosting the overall efficiency of the manufacturing process.In addition to durability, the YG8 Tungsten Carbide Cold Heading Dies also deliver superior performance in terms of dimensional accuracy and surface finish. The high hardness and toughness of tungsten carbide ensure that the dies can maintain their shape and size over extended periods, resulting in consistent and precise forming of metal blanks. With tighter tolerances and improved surface finishes, manufacturers can eliminate the need for additional machining operations, streamlining their production processes and achieving faster turnaround times.Furthermore, the YG8 brand prides itself on delivering customization options to cater to specific cold heading requirements. Whether it is specialized and intricate shapes or unique dimensions, YG8 provides tailored solutions to meet diverse customer needs. This flexibility allows manufacturers to fully optimize their cold heading processes, producing parts that adhere to the highest standards of quality and functionality.To ensure the utmost product reliability, YG8 Tungsten Carbide Cold Heading Dies undergo stringent quality control measures during the manufacturing process. This includes rigorous testing for hardness, toughness, and dimensional accuracy. By adhering to the highest quality standards, YG8 guarantees that only top-notch products reach the hands of its customers, enabling them to achieve unparalleled results in their cold forging operations.As the demand for precision metal components continues to rise, the importance of selecting the right tools and materials cannot be overstated. The YG8 Tungsten Carbide Cold Heading Dies stand as a testament to the commitment of providing manufacturers with innovative and high-quality solutions. With their exceptional durability, accuracy, and customization options, the YG8 brand is poised to revolutionize the cold forging industry, enabling manufacturers to stay ahead of the competition and meet the evolving needs of their customers.

Maximizing the Benefits of Tungsten Carbide in Cold Heading Applications

Tungsten Carbide Cold Heading: The Perfect Solution for Your Fastening Needs Fastening systems have come a long way in recent years with advancements in technology and material sciences. One such advancement in fastening systems is Tungsten Carbide Cold Heading. Compared to other materials, Tungsten Carbide Cold Heading has the ability to withstand extreme temperatures, wear and tear, and chemical reactions.With the increase in demand for fastening solutions, Tungsten Carbide Cold Heading has become the primary choice of many industries, including automotive, aerospace, and construction.What is Tungsten Carbide Cold Heading?Tungsten Carbide Cold Heading comprises a high percentage of tungsten carbide, typically ranging anywhere between 85%- 95%, mixed with a binding agent such as cobalt or nickel. The process of forming Tungsten Carbide Cold Heading involves compressing the material into shape while it's in its cold state.The compression process results in homogeneous grain structure, providing a unique combination of strength, hardness, and fracture toughness. The production process of Tungsten Carbide Cold Heading ensures that the material can withstand any amount of wear and tear and provide long-lasting, reliable fastening solutions.Applications and Advantages of Tungsten Carbide Cold HeadingTungsten Carbide Cold Heading is a versatile material used for various fastening applications. One of the primary applications of Tungsten Carbide Cold Heading is manufacturing cold-formed parts, including screws, bolts, nuts, and other fasteners.Due to the high energy absorption properties of Tungsten Carbide Cold Heading, they are also used in the construction industry to manufacture heavy machinery and equipment parts. Tungsten Carbide Cold Heading's resistance to wear and tear, resistance to extreme temperatures, and chemical inertness makes it suitable for use in harsh environments such as mining equipment and oil rigs.Another application of Tungsten Carbide Cold Heading is in the aerospace industry, where the material is ideal for manufacturing turbine engine blades and other aircraft parts. The unique characteristics of Tungsten Carbide Cold Heading, including its strength, wear resistance, and durability, make it the preferred material in the aerospace industry.Apart from this, several other advantages of Tungsten Carbide Cold Heading make it an ideal choice for various applications. For instance:1. Resistance to Wear and TearTungsten Carbide Cold Heading's high hardness, low friction, and exceptional wear resistance make it an ideal choice for applications that require lasting durability. The material can withstand high stress and maintain its shape, even under extreme conditions.2. High StrengthThe high strength of Tungsten Carbide Cold Heading makes it ideal for applications that require strong and durable fastening solutions. The material's strength makes it ideal for heavy construction machinery parts, aerospace turbine blades, and automotive engine components.3. Resistance to Extreme TemperaturesTungsten Carbide Cold Heading's ability to withstand extreme temperatures, ranging from -273°C to 500°C, makes it suitable for use in harsh environments. The material's resistance to high temperatures makes it ideal for use in the oil and gas industry, where temperatures can exceed 200°C.4. Chemical InertnessThe chemical inertness of Tungsten Carbide Cold Heading makes it an ideal choice for use in corrosive environments. The material's chemical stability makes it resistant to corrosion, erosion, and oxidation, ensuring long-lasting durability.5. High Fracture ToughnessThe high fracture toughness of Tungsten Carbide Cold Heading makes it suitable for applications that require resistance to cracking and damage. The material's fracture toughness enables it to withstand high impact forces, making it ideal for use in high-stress environments.Introducing the Leading Tungsten Carbide Cold Heading ManufacturerOur company is a leading manufacturer of Tungsten Carbide Cold Heading. We specialize in producing high-quality, reliable, and affordable Tungsten Carbide Cold Heading solutions for various industries. Our production process uses the latest technology and adheres to the highest quality standards to ensure that our products exceed your expectations.We take pride in our ability to provide excellent customer service, timely delivery of products, and expert technical support. Our team of experts works closely with you to ensure that our Tungsten Carbide Cold Heading solutions meet your specific requirements.Final ThoughtsAs the demand for robust, reliable, and durable fastening systems continues to grow, Tungsten Carbide Cold Heading has become the primary choice of many industries. The unique characteristics of Tungsten Carbide Cold Heading, including high strength, resistance to wear and tear, and robustness, make it an ideal material for use in extreme conditions.If you're looking for a reliable supplier of Tungsten Carbide Cold Heading solutions, look no further than our company. We specialize in providing high-quality Tungsten Carbide Cold Heading products that meet your specific requirements. Contact us today to learn more about our Tungsten Carbide Cold Heading solutions.

Cemented Carbide Pallets: A Leading Solution for Durable Industrial Applications

Title: Innovative Cemented Carbide Pallets Revolutionize Industrial ApplicationsIntroduction:In the constantly evolving landscape of industrial tools and materials, cemented carbide pallets have emerged as a game-changer. These exceptionally durable and versatile tools have gained immense popularity for their ability to withstand extreme conditions, enhance productivity, and improve manufacturing processes across various industries.Company Introduction:{Company Name} is a renowned leader in the development and production of cemented carbide pallets. With years of experience and a proven track record of delivering high-quality solutions, {Company Name} has established itself as a trusted provider of innovative tools for diverse industrial applications. Combining cutting-edge technology, meticulous research, and a commitment to excellence, {Company Name} continues to set new benchmarks in the manufacturing industry.[Paragraph 1 - Cemented Carbide Pallets Overview]Cemented carbide pallets, also known as hard metal pallets, are manufactured from a combination of metal carbide and binder metals. This unique composition results in a superior material that is incredibly resistant to wear, corrosion, and heat. The exceptional strength and hardness of these pallets make them ideal for use in a wide range of industrial applications where traditional tools fall short.[Paragraph 2 - Unmatched Durability]One of the key features that sets cemented carbide pallets apart from conventional tools is their unparalleled durability. Thanks to their exceptional hardness, these pallets can withstand extreme conditions and abrasive materials without losing their effectiveness. They can endure high temperatures, heavy impacts, pressure, and exposure to corrosive agents, ensuring robust performance and prolonged tool life.[Paragraph 3 - Enhanced Productivity]With cemented carbide pallets, industries can optimize their efficiency and maximize productivity. The superior hardness and wear resistance of these pallets eliminate the need for frequent tool changes, reducing downtime and increasing operational speed. This results in improved manufacturing processes and significant cost savings, making cemented carbide pallets a preferred choice for various industries, including automotive, aerospace, mining, and manufacturing.[Paragraph 4 - Versatile Applications]The versatility of cemented carbide pallets is another aspect that makes them invaluable to industries. These pallets are available in a range of shapes and sizes, tailored to meet the specific requirements of different machining operations. From cutting, drilling, and shaping to grinding and milling, cemented carbide pallets can handle a variety of tasks with precision. Their exceptional performance in tooling applications enables industries to achieve greater accuracy and finer finishes.[Paragraph 5 - Sustainability]In addition to their remarkable performance, cemented carbide pallets contribute to sustainable manufacturing. The long lifespan of these pallets reduces waste generated from frequent tool replacements, minimizing the environmental impact. Furthermore, their improved efficiency and reduced energy consumption significantly lower carbon emissions during the manufacturing process. By opting for cemented carbide pallets, industries can align their operations with sustainable practices and contribute to a greener future.[Paragraph 6 - Ongoing research and development]{Company Name} recognizes the importance of continuous innovation and investment in research and development. Committed to staying ahead of the curve, the company consistently explores new materials, advanced manufacturing techniques, and improved designs for cemented carbide pallets. This ensures that their customers always have access to the latest technologies and solutions to address their evolving needs and challenges.[Paragraph 7 - Conclusion]Cemented carbide pallets have revolutionized the industrial landscape, offering exceptional durability, enhanced productivity, versatility, and sustainability. With {Company Name} leading the way in their development and production, industries can embrace these innovative tools to optimize their processes and achieve unprecedented results. As the demand for reliable and high-performance tools continues to grow, cemented carbide pallets are set to become an indispensable asset across a myriad of industries, driving progress and shaping the future of manufacturing.

Applications of Tungsten Carbide: A Versatile Industrial Material

Title: Tungsten Carbide: Revolutionizing Industries with Unparalleled VersatilityIntroduction:In the world of industrial applications, Tungsten Carbide has emerged as a game-changing material renowned for its exceptional hardness, durability, and versatility. With its remarkable properties and myriad of applications, this composite material has found its way into various industries, transforming manufacturing processes and enhancing product performance. This article delves into the multifaceted use of Tungsten Carbide and its profound impact on different sectors of the global economy.1. Automotive Industry:From precision cutting tools to durable automotive components, Tungsten Carbide is revolutionizing the automotive sector. In cutting-edge engine manufacturing, Tungsten Carbide inserts in tooling systems play a vital role in delivering precise and high-speed machining with superior surface finish. Mechanical seals made from this robust material ensure leak-free operation in automotive water pumps and ensure prolonged service life. Moreover, the use of Tungsten Carbide in brake pads and clutch facings improves braking performance and enhances durability, ensuring driver safety.2. Oil and Gas Industry:The oil and gas industry heavily relies on Tungsten Carbide due to its exceptional wear resistance and high-temperature stability. Exploration and drilling operations utilize hard-facing applications, such as drill bits, to withstand extreme working conditions while maximizing drilling efficiency. Furthermore, Tungsten Carbide components in downhole tools, such as stabilizers and wear-resistant valves, endure the challenging environment and enhance operational reliability. By offering superior resistance to erosion and corrosion, Tungsten Carbide ensures increased productivity and reduced downtime in the oil and gas sector.3. Mining and Construction:In the mining and construction sectors, where equipment operates in harsh environments, Tungsten Carbide plays a crucial role in enhancing equipment longevity and efficiency. The use of Tungsten Carbide in drill bits, augers, and tooling systems allows for improved penetration rates and extended tool life. Excavation buckets and teeth made from this material withstand abrasion from rocks and other challenging geological conditions, reducing maintenance costs and increasing productivity. The mining industry benefits greatly from the advanced performance and reliability offered by Tungsten Carbide, enabling extraction operations to occur seamlessly and efficiently.4. Metalworking and Tooling:Tungsten Carbide is widely acclaimed in the metalworking industry for its exceptional resistance to wear, deformation, and high temperatures. Cutting inserts and end mills made from this composite material offer superior cutting speed, precision, and surface finish, thereby enhancing overall machining productivity. Tungsten Carbide tooling systems also find extensive applications in the woodworking industry, where they deliver increased cutting efficiency and improved finish quality. These properties make Tungsten Carbide an indispensable choice for manufacturing sectors, guaranteeing efficiency and precision in every operation.5. Electronics and Semiconductors:In the rapidly advancing field of electronics and semiconductors, Tungsten Carbide is sought after for its electrical conductivity and resistance to wear and heat. The material is widely used in the production of semiconductor dies, integrated circuit packages, and wire bonding tools, ensuring reliable and durable electronic devices. Tungsten Carbide's remarkable electrical conductivity, coupled with its high strength, makes it an indispensable choice for electronics manufacturers.Conclusion:Tungsten Carbide's unique blend of hardness, durability, and versatility has transformed various industries and manufacturing processes worldwide. From automotive components to oil and gas equipment, mining tools to metalworking applications, and electronics to semiconductors, this exceptional material has proven to be an invaluable asset for enhancing product performance, increasing productivity, and reducing maintenance costs. As technological advancements continue to shape our world, Tungsten Carbide remains at the forefront, playing a pivotal role in shaping a more efficient and sustainable future across multiple sectors.

Premium Tungsten Carbide Roller: Bringing Unparalleled Polished Finishing

Title: Cutting-Edge Tungsten Carbide Roller Revolutionizes Manufacturing IndustryIntroduction:In our rapidly evolving manufacturing industry, innovation and cutting-edge technology continue to enhance production processes and improve product quality. One such revolutionizing development comes in the form of the Polished Tungsten Carbide Roller, developed by a renowned industry leader (company name).Groundbreaking Technology Enhancing Manufacturing Processes:Tungsten carbide possesses exceptional hardness and resistance to wear, making it an ideal material for manufacturing rollers used in various industries. By incorporating state-of-the-art polishing techniques, the (company name) Polished Tungsten Carbide Roller has taken the performance and efficiency of manufacturing processes to unprecedented heights.Precision and Enhanced Durability:The innovative design of the Polished Tungsten Carbide Roller ensures unparalleled precision, enabling manufacturers to achieve superior results in their production lines. The roller's polished surface significantly reduces friction, resulting in reduced wear and tear. This not only leads to enhanced durability but also extends the product's lifespan, reducing maintenance costs for manufacturers.Versatility Across Industries:The Polished Tungsten Carbide Roller caters to a diverse range of industries, including steel, aluminum, plastic, textile, and paper. Its versatility lies in the roller's ability to withstand extreme environments, high temperatures, corrosive chemicals, and heavy loads. This adaptability ensures that manufacturers can benefit from this groundbreaking technology across various applications.Smoother Operations and Improved Product Quality:With its reduced friction and enhanced durability, the Polished Tungsten Carbide Roller contributes to smoother operations, minimizing downtime and maximizing production efficiency. Its high precision and surface finish guarantee consistent and accurate results, thereby improving product quality and reducing the margin of error.Cost and Energy Efficiency:In addition to its exceptional performance, the Polished Tungsten Carbide Roller also promotes cost and energy efficiency. Its high wear resistance ensures less frequent replacements and maintenance, resulting in reduced operational costs for manufacturers. Additionally, the roller's improved efficiency minimizes energy consumption, making it an environmentally friendly choice.Commitment to Quality Assurance and Safety:As a leader in the manufacturing industry, (company name) prioritizes quality assurance and safety standards. The Polished Tungsten Carbide Roller undergoes rigorous testing and adheres to stringent quality control measures, ensuring that each roller meets or exceeds industry specifications. This commitment to excellence guarantees customer satisfaction and reliable performance for manufacturers in various fields.Global Reach and Customer Satisfaction:Backed by years of research and development, (company name) has built a strong reputation for delivering superior products worldwide. The Polished Tungsten Carbide Roller has garnered positive feedback from clients across the globe, who appreciate the roller's remarkable performance, increased efficiency, and unmatched durability. Customer satisfaction remains at the core of (company name)'s mission, driving them to continually innovate and meet the evolving needs of the industry.Conclusion:The Polished Tungsten Carbide Roller developed by (company name) has emerged as a game-changer in the manufacturing industry, enabling manufacturers to achieve unparalleled precision, efficiency, and durability. Through its innovative design and incorporation of cutting-edge polishing techniques, this revolutionary roller has set new standards for manufacturing processes across a wide range of industries. With its global success and commitment to customer satisfaction, (company name) continues to pave the way for future advancements in the manufacturing industry.